Intro

Learn to design and 3D print your own custom clamp with ease. Discover the step-by-step process of creating a functional 3D printable clamp, from modeling to printing. Master the art of designing and printing clamps for various applications, including woodworking, DIY projects, and more, with expert tips and tricks.

The world of 3D printing has opened up a whole new realm of possibilities for makers and DIY enthusiasts. With the ability to design and print custom objects, the limitations of traditional manufacturing are a thing of the past. One of the most versatile and practical objects you can create is a 3D printable clamp. In this article, we'll explore the world of 3D printable clamps, their benefits, and provide a step-by-step guide on how to design and print your own.

Benefits of 3D Printable Clamps

Before we dive into the design and printing process, let's take a look at the benefits of 3D printable clamps:

- Customization: With 3D printing, you can design a clamp that fits your specific needs. Whether it's a small clamp for holding tiny parts or a large clamp for securing heavy materials, the possibilities are endless.

- Cost-effective: 3D printing eliminates the need for expensive tooling and molds, making it a cost-effective solution for producing clamps.

- Speed: 3D printing allows for rapid prototyping and production, which means you can have a functional clamp in your hands in a matter of hours, not days or weeks.

- Durability: 3D printed clamps can be designed with strength and durability in mind, making them suitable for a wide range of applications.

Designing Your 3D Printable Clamp

Designing a 3D printable clamp requires some basic knowledge of CAD software and 3D modeling. Here are the steps to follow:

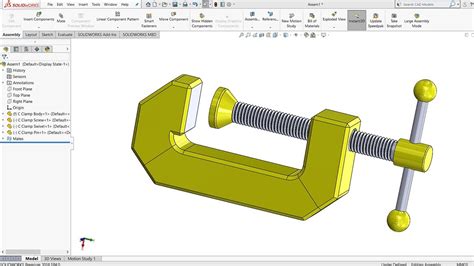

- Choose a CAD software: There are many CAD software options available, including Tinkercad, Fusion 360, and Blender. Choose one that you're comfortable with and has the features you need.

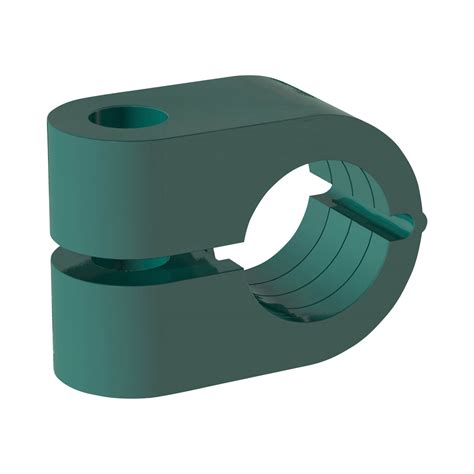

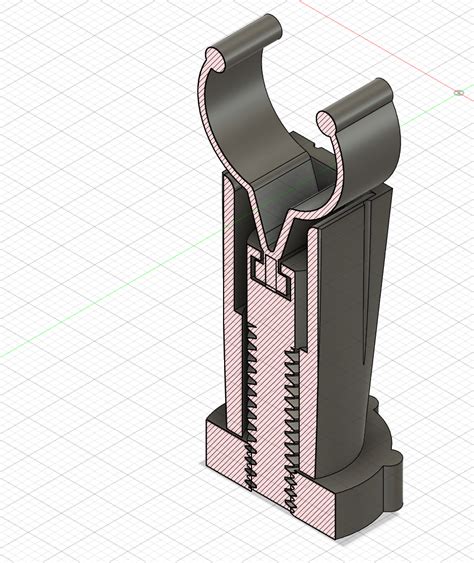

- Design the clamp body: Start by designing the main body of the clamp. Consider the size, shape, and material you'll be using. Make sure it's strong and durable enough for your intended use.

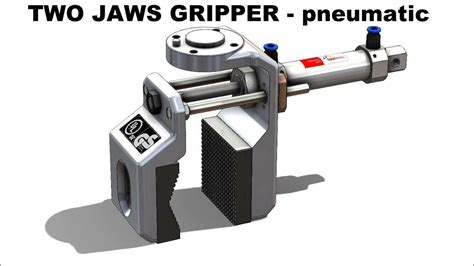

- Add the jaw mechanism: The jaw mechanism is the part of the clamp that grips the material. You can design a simple screw-based mechanism or a more complex cam-based system.

- Add the handle: The handle is the part of the clamp that you'll use to apply pressure. Make sure it's comfortable to grip and has enough leverage to apply the necessary force.

- Refine the design: Once you have the basic design, refine it by adding details such as holes for screws, fillets for smooth edges, and a chamfer for easy assembly.

Preparing Your 3D Printable Clamp for Printing

Once you have your design, it's time to prepare it for printing. Here are the steps to follow:

- Export the design: Export your design as an STL file, which is the standard file format for 3D printing.

- Slice the model: Use slicing software such as Cura or Slic3r to slice your model into layers. This will create a G-code file that your 3D printer can read.

- Configure the print settings: Configure the print settings such as layer height, infill density, and support material.

Printing Your 3D Printable Clamp

With your design prepared, it's time to print your clamp. Here are the steps to follow:

- Load the G-code file: Load the G-code file into your 3D printer's software.

- Start the print: Start the print job and let the printer do its magic.

- Monitor the print: Monitor the print job to ensure that it's printing correctly.

Post-Printing and Assembly

Once the print job is complete, it's time to assemble the clamp. Here are the steps to follow:

- Remove the support material: Remove the support material from the clamp.

- Assemble the jaw mechanism: Assemble the jaw mechanism by attaching the screws or other hardware.

- Attach the handle: Attach the handle to the clamp body.

- Test the clamp: Test the clamp to ensure that it's working correctly.

Tips and Tricks

Here are some tips and tricks to keep in mind when designing and printing your 3D printable clamp:

- Use a strong material: Use a strong material such as ABS or PETG for the clamp body and jaw mechanism.

- Add a non-slip surface: Add a non-slip surface to the jaw mechanism to prevent slipping.

- Use a spring: Use a spring to provide additional force to the jaw mechanism.

Conclusion

Designing and printing your own 3D printable clamp is a fun and rewarding project. With the right design and printing techniques, you can create a clamp that's customized to your specific needs. Remember to use a strong material, add a non-slip surface, and use a spring to provide additional force. Happy printing!

3D Printable Clamp Image Gallery

We hope you've enjoyed this article on designing and printing your own 3D printable clamp. If you have any questions or comments, please feel free to share them below.