Intro

Discover the world of 3D printable gearbox designs and models. Learn how to create complex mechanical transmissions with 3D printing technology. Explore various gearbox models, including planetary gears, robotic transmissions, and more. Get insights on designing and printing custom gearboxes for robotics, drones, and other applications.

The world of 3D printing has revolutionized the way we design and create complex mechanical systems, and one area that has seen significant innovation is gearbox design. A gearbox is a crucial component in many mechanical systems, allowing for the transmission of rotational energy between two or more shafts, often with a change in speed or torque. With 3D printing, designers and engineers can now create complex gearbox designs and models with unprecedented ease and accuracy.

Benefits of 3D Printable Gearbox Designs

The use of 3D printing in gearbox design offers several benefits, including:

- Increased complexity: 3D printing allows for the creation of complex geometries and shapes that would be difficult or impossible to produce with traditional manufacturing methods.

- Reduced material waste: 3D printing is an additive process, meaning that material is only added as needed, reducing waste and conserving resources.

- Faster prototyping: 3D printing enables rapid prototyping and testing of gearbox designs, allowing designers to iterate and refine their designs quickly.

- Customization: 3D printing allows for the creation of custom gearbox designs tailored to specific applications or requirements.

Types of 3D Printable Gearbox Designs

There are several types of gearbox designs that can be created using 3D printing, including:

- Spur gearboxes: These are the most common type of gearbox, using straight-cut teeth to transmit rotational energy.

- Helical gearboxes: These use angled teeth to transmit rotational energy, often used in applications where high torque is required.

- Worm gearboxes: These use a worm gear to transmit rotational energy, often used in applications where high speed is required.

- Planetary gearboxes: These use a combination of gears and shafts to transmit rotational energy, often used in applications where high torque and speed are required.

Design Considerations for 3D Printable Gearbox Models

When designing 3D printable gearbox models, there are several considerations to keep in mind, including:

- Material selection: The choice of material will depend on the application and requirements of the gearbox. Common materials used for 3D printing include plastics, metals, and ceramics.

- Gear tooth design: The design of the gear teeth will depend on the type of gearbox and the application. Considerations include tooth shape, size, and spacing.

- Shaft design: The design of the shafts will depend on the application and requirements of the gearbox. Considerations include shaft diameter, length, and material.

- Bearing design: The design of the bearings will depend on the application and requirements of the gearbox. Considerations include bearing type, size, and material.

Software Tools for 3D Printable Gearbox Design

There are several software tools available for designing 3D printable gearbox models, including:

- Computer-aided design (CAD) software: CAD software such as Autodesk Inventor, SolidWorks, and Fusion 360 can be used to create 2D and 3D models of gearbox designs.

- 3D modeling software: 3D modeling software such as Blender and Tinkercad can be used to create complex geometries and shapes.

- Gearbox design software: Specialized software such as GearLab and GearTrain can be used to design and analyze gearbox models.

Applications of 3D Printable Gearbox Designs

3D printable gearbox designs have a wide range of applications, including:

- Robotics: 3D printed gearboxes are often used in robotics applications where high precision and accuracy are required.

- Aerospace: 3D printed gearboxes are used in aerospace applications where high strength-to-weight ratios are required.

- Automotive: 3D printed gearboxes are used in automotive applications where high torque and speed are required.

- Medical devices: 3D printed gearboxes are used in medical devices such as surgical instruments and diagnostic equipment.

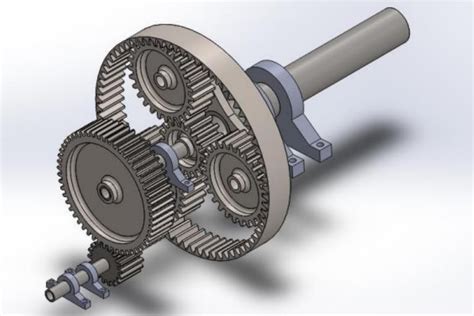

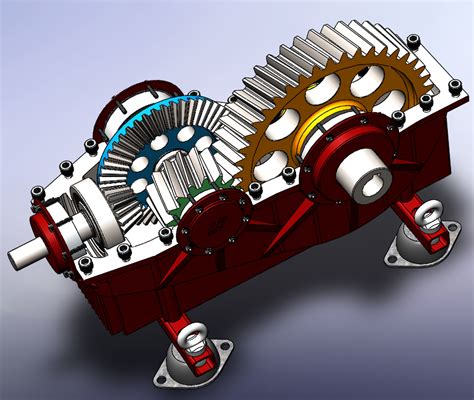

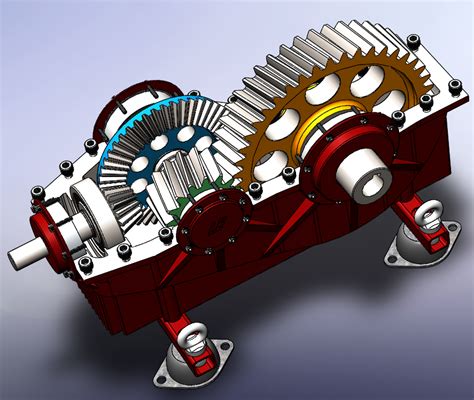

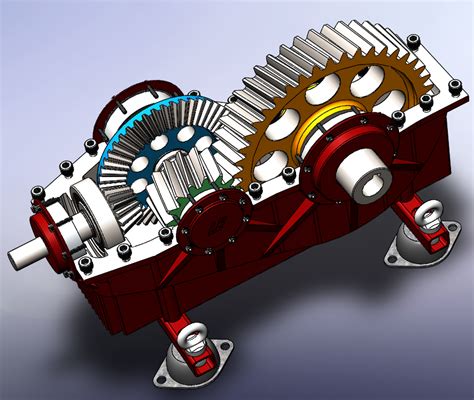

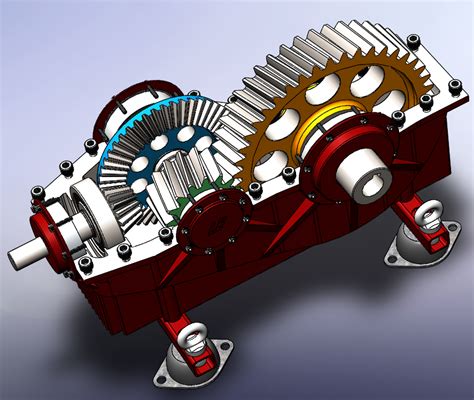

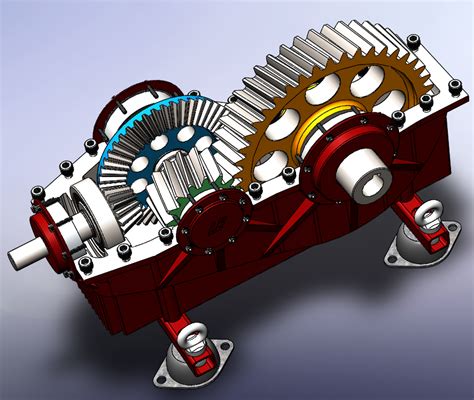

Gearbox Design Gallery

We hope this article has provided you with a comprehensive overview of 3D printable gearbox designs and models. Whether you're a designer, engineer, or simply interested in learning more about gearbox design, we encourage you to share your thoughts and experiences in the comments below.