5 Steps To Build 3d Printable Rc Airplane Summary

Design and build your own 3D printable RC airplane with these 5 easy steps. Learn how to create a custom model, choose the right materials, and assemble your aircraft. Discover the best 3D printing techniques and RC airplane design tips for a successful flight. Get ready to take to the skies with your DIY RC plane.

Building a 3D printable RC airplane is an exciting project that combines the thrill of flying with the cutting-edge technology of 3D printing. With the right design, materials, and tools, you can create a customized RC airplane that is both durable and aerodynamic. Here are the 5 steps to build a 3D printable RC airplane:

Step 1: Design Your Airplane

Before you start printing, you need to design your airplane. You can use computer-aided design (CAD) software or online tools to create a digital model of your airplane. Consider the type of airplane you want to build, its size, shape, and weight. You can also choose from various pre-made designs available online.

When designing your airplane, keep in mind the following factors:

- Wing shape and size

- Fuselage shape and size

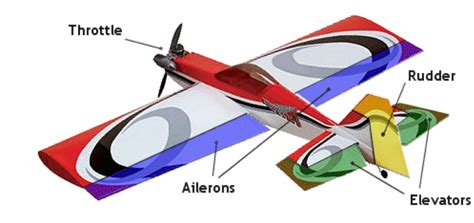

- Control surfaces (ailerons, elevators, rudder)

- Landing gear

- Motor and propeller placement

Use software like Blender, Tinkercad, or Fusion 360 to create your design. You can also use online tools like Thingiverse or MyMiniFactory to find pre-made designs.

Step 2: Prepare Your 3D Printing Files

Once you have your design, you need to prepare your 3D printing files. This involves converting your CAD file into a format that your 3D printer can understand.

Use software like Slic3r or Cura to slice your CAD file into layers that your 3D printer can print. You can also use online tools like MakeXYZ or Printalyze to prepare your files.

Consider the following factors when preparing your files:

- Layer height and thickness

- Infill density and pattern

- Support material (if necessary)

- Printing orientation and layout

Step 3: Print Your Airplane Parts

With your files ready, you can start printing your airplane parts. Make sure you have the right 3D printing materials, such as PLA or ABS, and the right printer settings.

Print each part separately, starting with the wing, fuselage, and control surfaces. Use a brim or raft to prevent warping and ensure a smooth printing process.

Consider the following factors when printing your parts:

- Printing speed and temperature

- Layer adhesion and bonding

- Support material removal (if necessary)

Step 4: Assemble and Sand Your Airplane

Once you have printed all the parts, you need to assemble and sand your airplane. Use glue, screws, or other fastening methods to attach the parts together.

Sand your airplane to smooth out any rough edges or surfaces. Use a sanding block or sandpaper to achieve a smooth finish.

Consider the following factors when assembling and sanding your airplane:

- Joint strength and durability

- Surface finish and texture

- Weight and balance

Step 5: Add Electronics and Final Touches

Finally, you need to add electronics and final touches to your airplane. Install the motor, propeller, and control surfaces. Add a radio transmitter and receiver to control your airplane.

Consider the following factors when adding electronics and final touches:

- Motor and propeller selection

- Control surface alignment and adjustment

- Radio transmitter and receiver setup

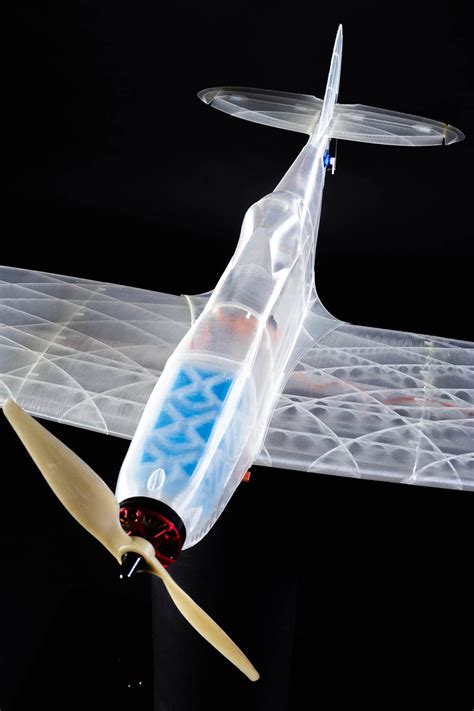

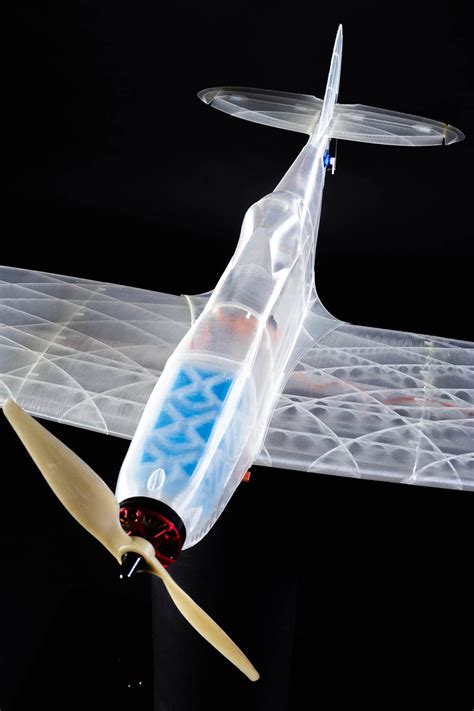

Gallery of 3D Printable RC Airplane Images

3D Printable RC Airplane Image Gallery

By following these 5 steps, you can build a 3D printable RC airplane that is both durable and aerodynamic. Remember to design your airplane carefully, prepare your 3D printing files correctly, print your parts accurately, assemble and sand your airplane smoothly, and add electronics and final touches carefully. Happy building!