Discover how 3D printed tanks are transforming modern warfare and manufacturing. Learn about the cutting-edge technology behind these innovative vehicles, their impact on military logistics and supply chains, and the future of additive manufacturing in the defense industry, revolutionizing the way we design, produce, and deploy combat vehicles.

The world of warfare and manufacturing is on the cusp of a revolution, thanks to the advent of 3D printed tanks. This game-changing technology is set to transform the way armies fight and industries produce, making it a crucial development in the modern era.

As the world becomes increasingly dependent on technology, the need for innovative solutions in warfare and manufacturing has never been more pressing. Traditional methods of producing tanks and other military vehicles are time-consuming, expensive, and often result in significant waste. However, with the emergence of 3D printing, these challenges can be overcome, paving the way for a new era of efficient and effective production.

Benefits of 3D Printed Tanks

The benefits of 3D printed tanks are numerous and far-reaching. Here are some of the most significant advantages:

- Reduced Production Time: 3D printing allows for rapid production, significantly reducing the time it takes to manufacture a tank. This means that armies can quickly respond to emerging threats and industries can meet increasing demand.

- Increased Efficiency: Traditional manufacturing methods often result in significant waste, with up to 90% of materials being discarded. 3D printing, on the other hand, uses a layer-by-layer approach, minimizing waste and reducing costs.

- Improved Customization: 3D printing enables the creation of customized tanks tailored to specific needs. This means that armies can design tanks that meet their unique requirements, and industries can produce vehicles that meet the specific needs of their customers.

- Enhanced Durability: 3D printed tanks are made from advanced materials that are stronger and more durable than traditional materials. This means that tanks can withstand the rigors of battle and harsh environments.

How 3D Printed Tanks Work

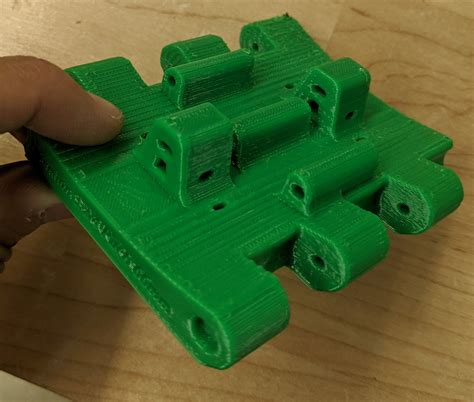

3D printed tanks are created using a process called additive manufacturing. This involves layering materials, such as metals and plastics, to create the desired shape and structure. The process is controlled by sophisticated software that ensures accuracy and precision.

Here's a step-by-step overview of how 3D printed tanks are made:

- Design: The design process begins with the creation of a digital model of the tank. This is done using computer-aided design (CAD) software.

- Materials: The materials used for 3D printing are selected based on their strength, durability, and weight. Common materials include metals, plastics, and ceramics.

- Layering: The 3D printing process involves layering the materials to create the desired shape and structure. This is done using a 3D printer, which is controlled by the CAD software.

- Finishing: Once the tank is printed, it undergoes a series of finishing processes, including sanding, painting, and assembly.

Applications of 3D Printed Tanks

3D printed tanks have a wide range of applications in both warfare and manufacturing. Here are some of the most significant uses:

- Military: 3D printed tanks can be used in various military applications, including combat, transport, and reconnaissance.

- Industrial: 3D printed tanks can be used in industrial settings, such as in the production of heavy machinery and equipment.

- Agricultural: 3D printed tanks can be used in agricultural settings, such as in the production of tractors and other farm equipment.

- Environmental: 3D printed tanks can be used in environmental applications, such as in the production of equipment for oil spills and other environmental disasters.

Challenges and Limitations

While 3D printed tanks offer numerous benefits, there are also challenges and limitations to consider. Here are some of the most significant ones:

- Scalability: 3D printing is still a relatively new technology, and scaling up production to meet demand can be a challenge.

- Cost: 3D printing is still a relatively expensive technology, making it inaccessible to some industries and countries.

- Regulations: There are still regulatory challenges to overcome, particularly in the military sector, where the use of 3D printed tanks is still a relatively new concept.

Future of 3D Printed Tanks

The future of 3D printed tanks is exciting and promising. As the technology continues to evolve, we can expect to see significant advancements in the following areas:

- Increased Adoption: As the benefits of 3D printed tanks become more widely recognized, we can expect to see increased adoption in both warfare and manufacturing.

- Improved Efficiency: Advances in 3D printing technology will enable faster and more efficient production, reducing costs and increasing productivity.

- New Materials: Researchers are continually developing new materials that are stronger, lighter, and more durable. These advancements will enable the creation of even more advanced 3D printed tanks.

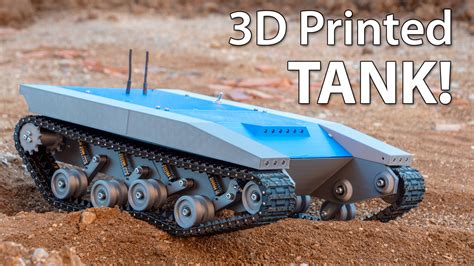

3D Printed Tank Image Gallery

As we look to the future, it's clear that 3D printed tanks will play a significant role in both warfare and manufacturing. With their numerous benefits, including reduced production time, increased efficiency, and improved customization, it's no wonder that 3D printed tanks are revolutionizing these industries. Whether you're a military leader, industrial manager, or simply someone interested in the latest technological advancements, 3D printed tanks are definitely worth keeping an eye on.