Intro

Master process control with our expert guide on how to calculate Cpk in Excel. Learn a step-by-step approach to measuring process capability and stability using Excel formulas and functions. Discover how to calculate Cpk, Cp, and Pp to optimize process performance and reduce variability. Boost quality control and decision-making with data-driven insights.

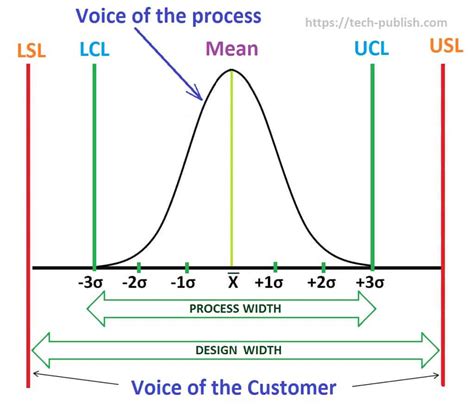

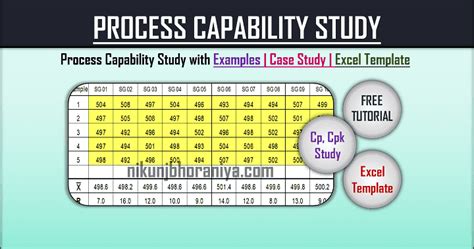

In the world of manufacturing and quality control, understanding the performance of a process is crucial to ensuring that products meet specifications and customer expectations. One key metric used to assess process performance is the process capability index, Cpk. Cpk is a statistical measure that compares the variability of a process to its specifications, providing insight into whether the process can produce output within desired limits. Calculating Cpk in Excel is a practical skill for quality control professionals and analysts, as it allows for quick and accurate assessment of process capabilities. In this article, we will delve into the details of Cpk, its importance, and provide a step-by-step guide on how to calculate it in Excel.

Understanding Cpk

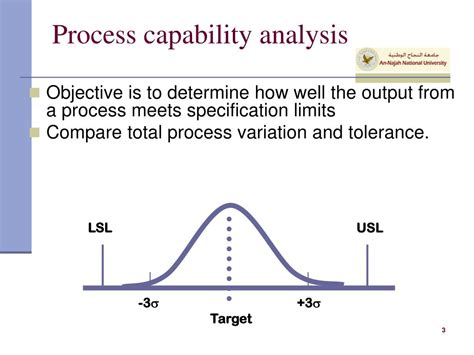

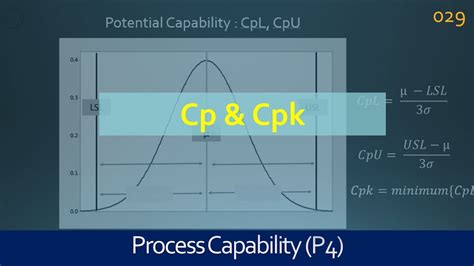

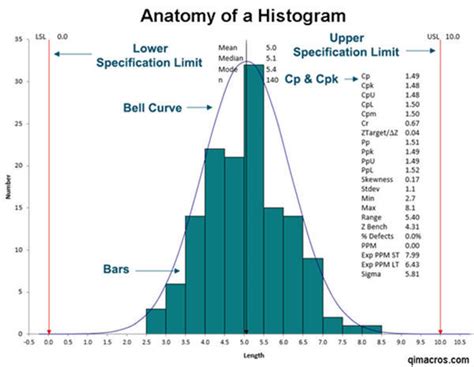

Cpk, or process capability index, is a measure of a process's ability to produce output within the specified limits. It takes into account both the mean (average) of the process and its variability (standard deviation). The Cpk value is calculated based on the mean, standard deviation, and the upper and lower specification limits (USL and LSL) of the process. A higher Cpk value indicates a more capable process, as it suggests that the process can consistently produce output within the desired specifications.

Why Cpk Matters

Cpk is a critical metric for several reasons:

- Assessing Process Performance: Cpk helps in evaluating whether a process is capable of meeting customer requirements.

- Reducing Defects: By ensuring that processes operate within desired specifications, Cpk helps in minimizing defects, which can lead to cost savings and improved customer satisfaction.

- Quality Improvement: Understanding process capabilities through Cpk allows for targeted improvement initiatives, focusing on reducing variability and centering the process mean.

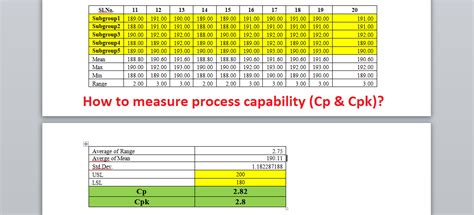

Calculating Cpk in Excel

Calculating Cpk in Excel involves several steps:

Step 1: Gather Data

- Collect a dataset of process output that represents a stable and normal distribution.

- Ensure that the data includes the upper and lower specification limits (USL and LSL).

Step 2: Calculate the Mean

- Use the

AVERAGEfunction in Excel to calculate the mean of your dataset. - Example:

=AVERAGE(A1:A100), assuming your data is in cells A1 through A100.

Step 3: Calculate the Standard Deviation

- Use the

STDEV.Sfunction in Excel to calculate the sample standard deviation of your dataset. - Example:

=STDEV.S(A1:A100), assuming your data is in cells A1 through A100.

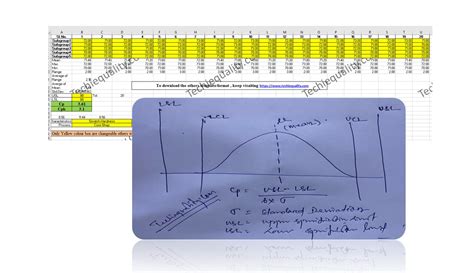

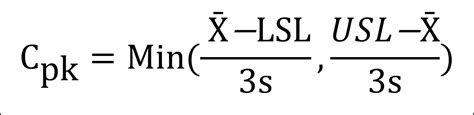

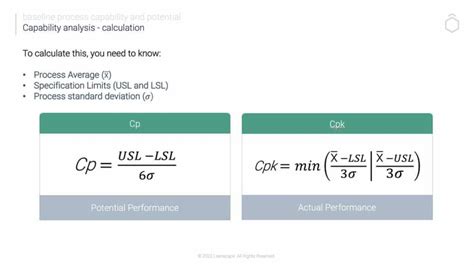

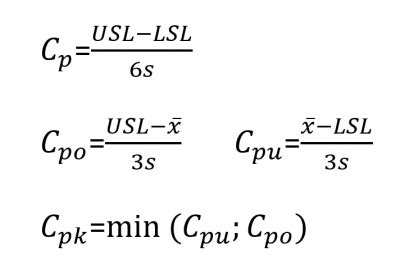

Step 4: Calculate Cpk

- Use the following formula to calculate Cpk:

Cpk = MIN((USL - μ) / (3*σ), (μ - LSL) / (3*σ)) - Where:

USLis the upper specification limit.LSLis the lower specification limit.μis the mean of the process.σis the standard deviation of the process.

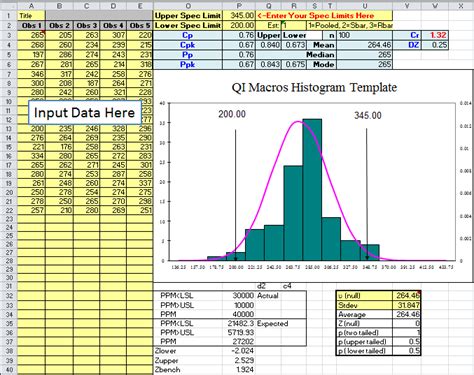

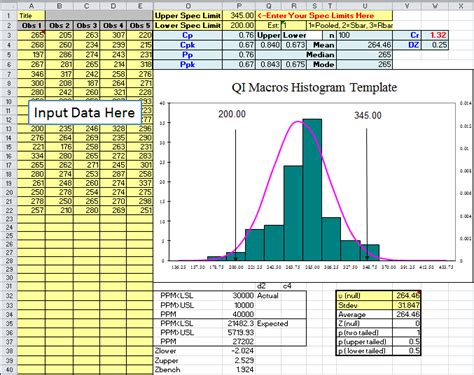

Example in Excel

Assuming your data is in cells A1:A100, with USL in cell B1 and LSL in cell C1, and using the mean and standard deviation calculated in steps 2 and 3:

=(MIN((B1-AVERAGE(A1:A100))/(3*STDEV.S(A1:A100)), (AVERAGE(A1:A100)-C1)/(3*STDEV.S(A1:A100))))

Interpreting Cpk Values

Cpk values can be interpreted as follows:

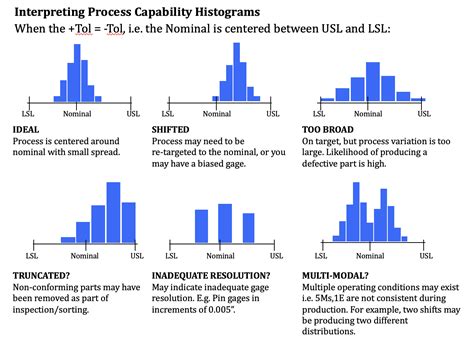

- Cpk < 1: The process is not capable, indicating that the variability of the process is too high relative to the specification limits.

- Cpk = 1: The process is minimally capable, suggesting that the process mean is centered, but the variability is such that the process output occasionally falls outside the specification limits.

- Cpk > 1: The process is capable, indicating that the process can consistently produce output within the desired specifications.

Gallery of Process Capability Indices

Process Capability Indices Image Gallery

Conclusion: Enhancing Process Performance with Cpk

Calculating Cpk in Excel is a straightforward process that can significantly enhance your ability to assess and improve process performance. By following the steps outlined in this guide and interpreting Cpk values effectively, you can identify opportunities for improvement and implement targeted initiatives to increase process capability. Whether you are in quality control, operations, or manufacturing, mastering the calculation of Cpk in Excel is a valuable skill that can contribute to improved product quality, reduced defects, and increased customer satisfaction.