Intro

Learn how to calculate Cpk in Excel with ease. Discover the 5 simple steps to measure process capability and ensure quality control. Master the process capability index (Cpk) formula and improve your manufacturing processes. Get expert tips on how to use Excel formulas to calculate Cpk, Ppk, and sigma levels.

In today's data-driven world, quality control is crucial for businesses to ensure their products meet customer expectations. One statistical tool used to measure process capability is the Cpk (Capability Index). Cpk measures the number of standard deviations between the process mean and the nearest specification limit. Calculating Cpk in Excel is a straightforward process, and we'll break it down into 5 easy steps.

Understanding Cpk and Its Importance

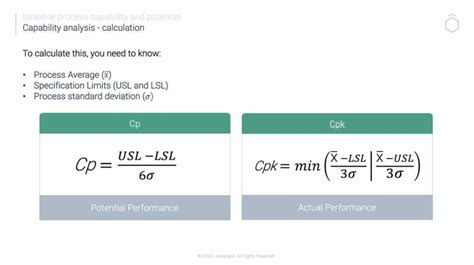

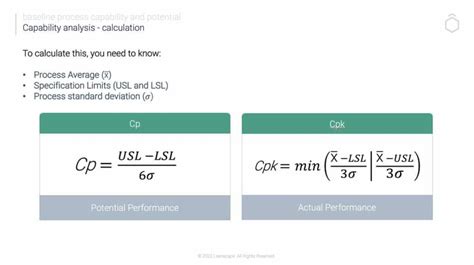

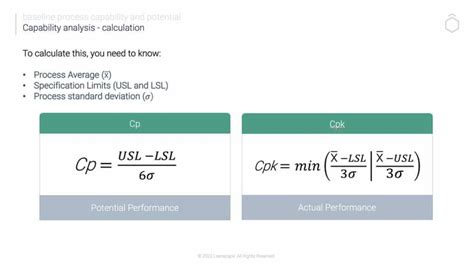

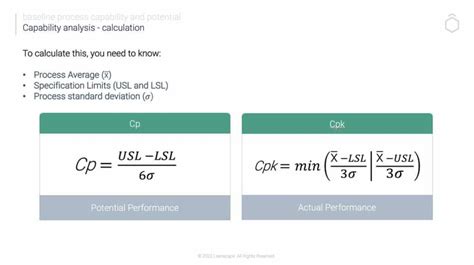

Before diving into the calculation process, it's essential to understand what Cpk represents and its significance in quality control. Cpk is a measure of a process's ability to produce output within specified limits. It's a dimensionless quantity that indicates how many standard deviations fit between the process mean and the nearest specification limit.

Cpk is crucial in identifying potential quality issues early on, allowing manufacturers to make necessary adjustments to their processes. By calculating Cpk, businesses can:

- Evaluate process performance

- Identify areas for improvement

- Monitor changes in process performance over time

- Set realistic quality targets

Step 1: Gather Data and Set Up Your Excel Worksheet

To calculate Cpk, you'll need to collect data on the process you want to evaluate. This data should include the process mean (μ), standard deviation (σ), and the upper and lower specification limits (USL and LSL).

Create a new Excel worksheet and set up the following columns:

| Column A | Column B | Column C | Column D |

|---|---|---|---|

| Data | Mean | Standard Deviation | USL |

| Data | LSL |

Enter your data in Column A, and calculate the mean and standard deviation using the AVERAGE and STDEV functions, respectively.

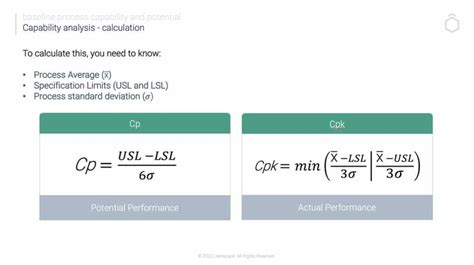

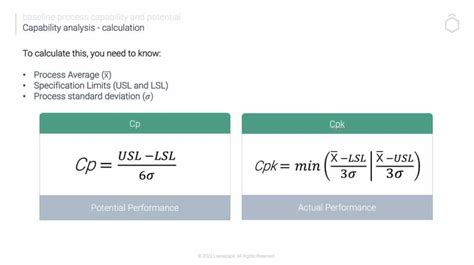

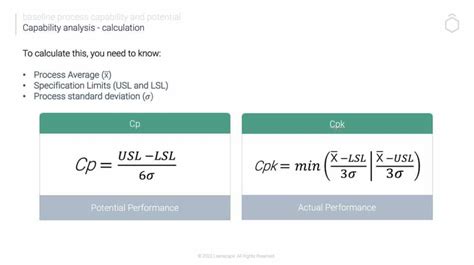

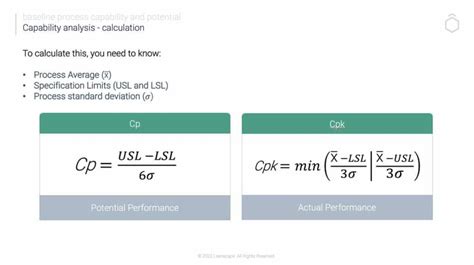

Step 2: Calculate the Process Capability

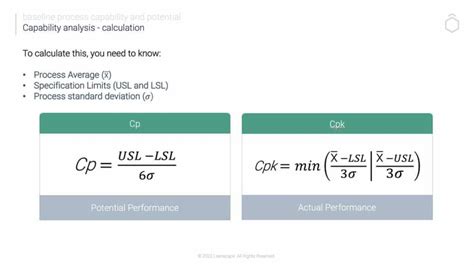

Next, you'll need to calculate the process capability using the following formula:

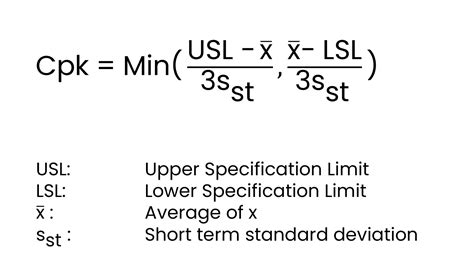

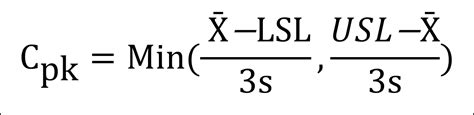

Cpk = min[(USL - μ) / (3σ), (μ - LSL) / (3σ)]

This formula calculates the minimum distance between the process mean and the nearest specification limit, expressed in standard deviations.

Create a new cell to calculate Cpk and use the MIN function to determine the minimum value between the two calculations.

Step 3: Calculate the Upper and Lower Cpk Values

To get a complete picture of the process capability, you'll need to calculate the upper and lower Cpk values. These values represent the number of standard deviations between the process mean and the upper and lower specification limits, respectively.

Create two new cells to calculate the upper and lower Cpk values using the following formulas:

Upper Cpk = (USL - μ) / (3σ) Lower Cpk = (μ - LSL) / (3σ)

Step 4: Interpret the Results

Once you've calculated the Cpk, upper Cpk, and lower Cpk values, it's essential to interpret the results. A Cpk value greater than 1 indicates that the process is capable of producing output within the specified limits. A value less than 1 indicates that the process may not be capable.

You can use the following guidelines to interpret the Cpk values:

| Cpk Value | Interpretation |

|---|---|

| > 1.33 | Excellent process capability |

| 1.00 - 1.33 | Good process capability |

| 0.67 - 1.00 | Fair process capability |

| < 0.67 | Poor process capability |

Step 5: Monitor and Improve the Process

The final step is to monitor the process and make improvements as needed. Regularly calculating Cpk values will help you identify changes in process performance over time. By analyzing these changes, you can identify areas for improvement and make necessary adjustments to maintain high-quality output.

Gallery of Cpk Calculation Examples

Cpk Calculation Examples

Conclusion: Take Control of Your Process Capability

Calculating Cpk in Excel is a straightforward process that can help you evaluate your process capability and identify areas for improvement. By following these 5 easy steps, you can take control of your process and ensure that your products meet customer expectations. Don't let quality issues hold you back – start calculating Cpk today and see the difference it can make in your business.

What's your experience with calculating Cpk? Share your thoughts and questions in the comments below!