Capacity planning is a crucial aspect of any organization's success, as it enables businesses to optimize resource allocation, reduce costs, and improve overall efficiency. However, creating a comprehensive capacity plan from scratch can be a daunting task, especially for those without extensive experience in operations management. Fortunately, there's a simple and effective solution: using an Excel template for capacity planning.

In this article, we'll delve into the world of capacity planning, exploring its importance, benefits, and challenges. We'll also provide a step-by-step guide on how to create a capacity plan using an Excel template, making it easier for you to get started.

What is Capacity Planning?

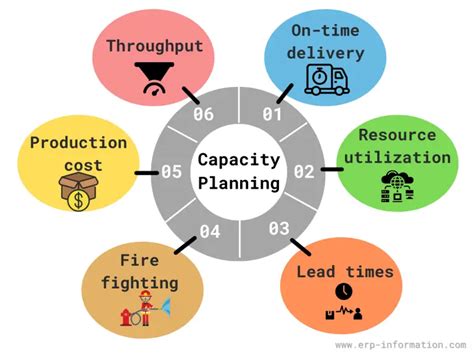

Capacity planning is the process of determining the optimal level of resources required to meet customer demand, while minimizing waste and maximizing efficiency. It involves analyzing various factors, such as production capacity, labor, equipment, and materials, to ensure that an organization has the necessary resources to deliver its products or services.

Why is Capacity Planning Important?

Capacity planning is essential for businesses of all sizes, as it helps to:

- Improve resource allocation and utilization

- Reduce waste and minimize idle time

- Increase productivity and efficiency

- Enhance customer satisfaction and loyalty

- Support strategic decision-making and business growth

Benefits of Using an Excel Template for Capacity Planning

Using an Excel template for capacity planning offers numerous benefits, including:

- Simplified planning and analysis

- Improved accuracy and reduced errors

- Enhanced collaboration and communication

- Increased flexibility and scalability

- Reduced costs and improved resource allocation

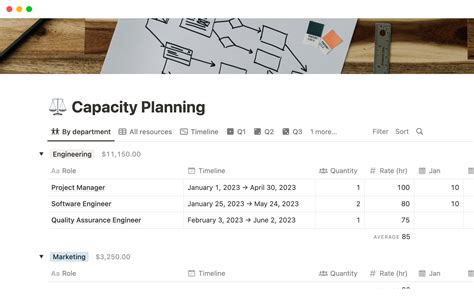

Creating a Capacity Plan Using an Excel Template

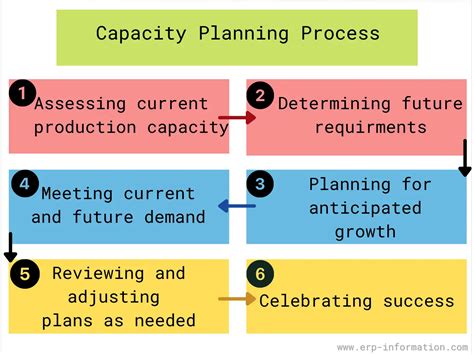

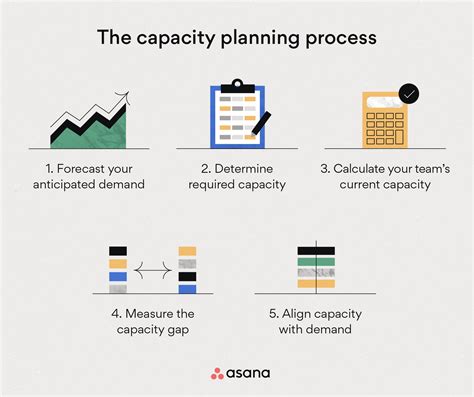

To create a capacity plan using an Excel template, follow these steps:

- Define your objectives: Identify your organization's goals and objectives, including production targets, resource allocation, and budget constraints.

- Gather data: Collect relevant data on your organization's resources, including equipment, labor, materials, and production capacity.

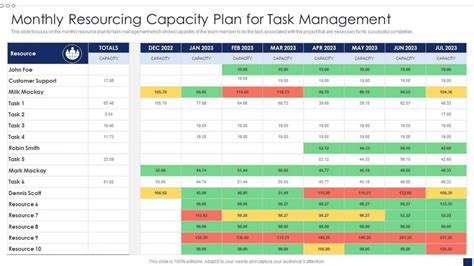

- Choose an Excel template: Select a suitable Excel template for capacity planning, or create your own using a spreadsheet software.

- Enter data: Input your data into the template, including production targets, resource allocation, and budget constraints.

- Analyze and adjust: Analyze your data and adjust your plan as necessary to ensure optimal resource allocation and utilization.

- Monitor and review: Regularly monitor and review your capacity plan to ensure it remains aligned with your organization's objectives and changing business needs.

Common Challenges in Capacity Planning

Capacity planning can be challenging, especially when dealing with complex production processes, variable demand, and limited resources. Common challenges include:

- Accurate demand forecasting: Predicting customer demand accurately to ensure optimal resource allocation.

- Resource constraints: Managing limited resources, such as equipment, labor, and materials.

- Production variability: Dealing with variable production processes, including quality control and maintenance.

- Budget constraints: Managing budget constraints and allocating resources effectively.

Best Practices for Capacity Planning

To overcome common challenges and create an effective capacity plan, follow these best practices:

- Use historical data: Analyze historical data to inform your capacity plan and improve accuracy.

- Collaborate with stakeholders: Engage with stakeholders, including production teams, suppliers, and customers, to ensure a comprehensive plan.

- Monitor and adjust: Regularly monitor your capacity plan and adjust as necessary to ensure optimal resource allocation and utilization.

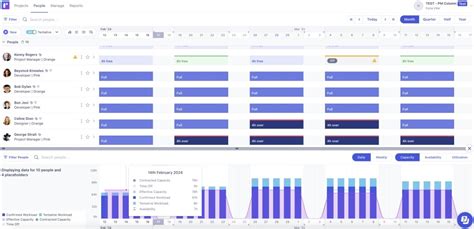

- Use technology: Leverage technology, such as Excel templates and simulation software, to simplify planning and analysis.

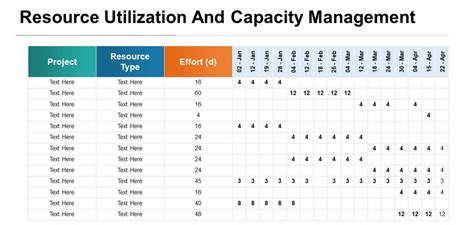

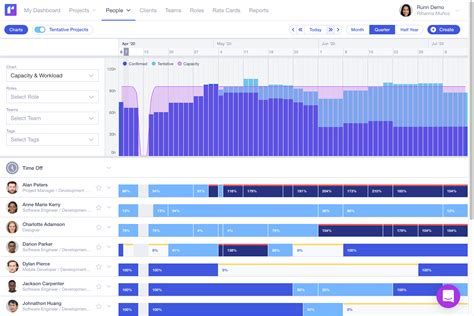

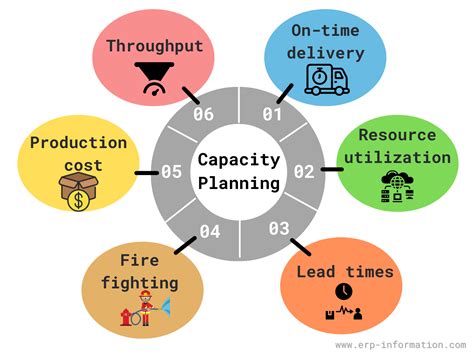

Capacity Planning Image Gallery

Conclusion

Capacity planning is a critical aspect of any organization's success, enabling businesses to optimize resource allocation, reduce costs, and improve overall efficiency. By using an Excel template for capacity planning, organizations can simplify the planning process, improve accuracy, and enhance collaboration. Remember to follow best practices, such as using historical data, collaborating with stakeholders, and monitoring and adjusting your plan regularly.

Share your thoughts on capacity planning and Excel templates in the comments below! Have you used an Excel template for capacity planning in the past? What were your experiences, and what benefits did you realize?