Intro

Discover the perfect fit with our comprehensive Chip Bag Template Size Guide. Learn how to choose the optimal template size for your packaging needs, ensuring a snug and secure fit for your products. Explore standard sizes, custom options, and expert tips to maximize efficiency and minimize waste in food packaging.

When it comes to packaging chips, the right template size is crucial for both functionality and aesthetics. A well-designed chip bag template can make a significant difference in the overall appeal of your product, while also ensuring that your chips are properly protected and easy to consume. In this article, we will delve into the world of optimal chip bag template sizes, exploring the various factors that influence their design and providing a comprehensive guide to help you choose the perfect template for your chip packaging needs.

The Importance of Template Size in Chip Packaging

The size of a chip bag template plays a critical role in determining the overall packaging efficiency, product visibility, and consumer satisfaction. A template that is too small may not provide sufficient space for branding and nutritional information, while a template that is too large may result in wasted material and increased production costs. Furthermore, a well-designed template can also influence the way your product is perceived by consumers, with a visually appealing design capable of boosting brand recognition and driving sales.

Factors Influencing Chip Bag Template Size

Several factors can influence the size of a chip bag template, including:

- Product size and shape: The size and shape of your chips will play a significant role in determining the optimal template size. For example, larger chips may require a bigger template, while smaller chips may be packaged in a smaller template.

- Packaging material: The type of packaging material used can also impact template size. For instance, a template designed for flexible packaging materials like plastic or paper may differ from one designed for rigid materials like cardboard.

- Branding and labeling requirements: The amount of space required for branding and labeling can also influence template size. Templates with more complex designs or larger labels may need to be bigger to accommodate these elements.

- Production efficiency: The size of the template can also impact production efficiency, with larger templates potentially reducing production time and costs.

Standard Chip Bag Template Sizes

While there is no one-size-fits-all approach to chip bag template design, there are several standard sizes that are commonly used in the industry. These include:

- Small: 3-4 inches wide, 5-6 inches tall ( ideal for small bags of chips or single-serve packets)

- Medium: 5-6 inches wide, 8-9 inches tall (suitable for standard bags of chips)

- Large: 7-8 inches wide, 10-11 inches tall (ideal for larger bags of chips or family-sized packs)

Customizing Your Chip Bag Template

While standard template sizes can provide a good starting point, many chip manufacturers opt for custom template designs that cater to their specific needs. This can involve adjusting the template size to accommodate unique product shapes or sizes, or incorporating custom design elements that reflect the brand's identity.

Benefits of Custom Chip Bag Templates

Custom chip bag templates can offer several benefits, including:

- Increased brand recognition: A custom template can help differentiate your product from competitors and reinforce your brand identity.

- Improved product visibility: A well-designed template can showcase your product in a more appealing way, making it more visible to consumers.

- Enhanced customer satisfaction: A custom template can also improve customer satisfaction by providing a more convenient and user-friendly packaging experience.

Designing Your Optimal Chip Bag Template

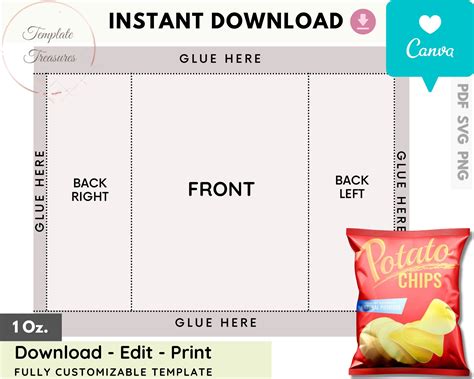

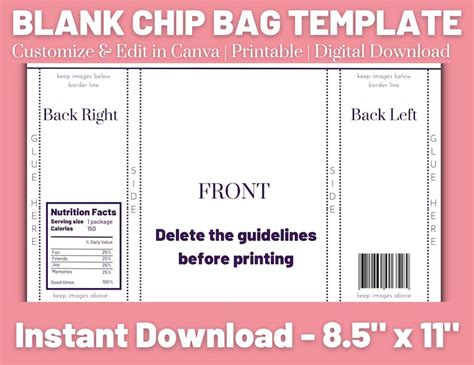

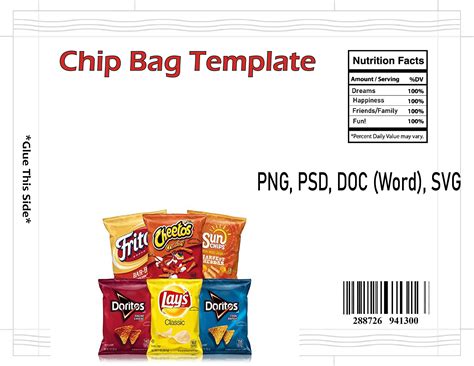

When designing your optimal chip bag template, consider the following key elements:

- Product window: A clear plastic window that allows consumers to see the product inside.

- Branding and labeling: A prominent display of your brand name and logo, as well as any relevant labeling information.

- Closure system: A secure closure system that prevents chips from spilling out during transportation or storage.

- Material selection: A durable and food-grade material that can protect the product and withstand various environmental conditions.

Best Practices for Chip Bag Template Design

To ensure your chip bag template design is both functional and visually appealing, follow these best practices:

- Keep it simple: Avoid cluttering the design with too much information or complex graphics.

- Use high-quality images: Incorporate high-quality images of your product to showcase its quality and appeal.

- Choose a clear font: Select a font that is clear and easy to read, especially for labeling information.

- Consider sustainability: Opt for eco-friendly materials and design elements that minimize waste and environmental impact.

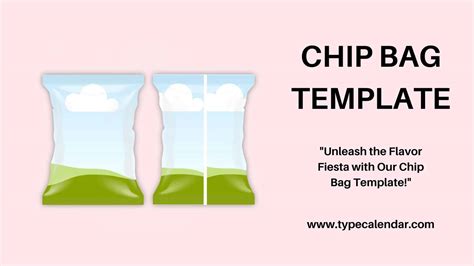

Gallery of Chip Bag Template Designs

Chip Bag Template Designs

Frequently Asked Questions

- What is the standard size for a chip bag template? The standard size for a chip bag template can vary depending on the type of chips and the packaging material used. However, common sizes include 3-4 inches wide, 5-6 inches tall (small), 5-6 inches wide, 8-9 inches tall (medium), and 7-8 inches wide, 10-11 inches tall (large).

- How do I design a custom chip bag template? To design a custom chip bag template, consider the product size and shape, packaging material, branding and labeling requirements, and production efficiency. You can also use design software or consult with a packaging expert to create a custom template that meets your specific needs.

- What are the benefits of using a custom chip bag template? Using a custom chip bag template can increase brand recognition, improve product visibility, and enhance customer satisfaction. It can also provide a unique and differentiated packaging solution that sets your product apart from competitors.

Conclusion

In conclusion, the optimal chip bag template size is crucial for both functionality and aesthetics. By considering factors such as product size and shape, packaging material, branding and labeling requirements, and production efficiency, you can design a template that meets your specific needs and enhances your product's appeal. Whether you choose a standard or custom template, following best practices for design and incorporating elements such as product windows, clear fonts, and sustainable materials can help ensure a successful packaging solution.