Intro

Discover the staggering costs behind the US aircraft carrier program. This in-depth breakdown reveals the billion-dollar expenses, from development and construction to operation and maintenance. Learn about the economic impact, defense budget allocation, and strategic value of these naval behemoths, and how they shape the nations military presence and global influence.

The United States has the largest and most advanced naval fleet in the world, with a significant portion of its budget allocated to the construction and maintenance of its aircraft carriers. These massive warships are the centerpiece of the US Navy's power projection capabilities, serving as floating airbases that can deploy aircraft, troops, and supplies to any part of the world. However, the cost of building and operating these behemoths is staggering, with a single aircraft carrier costing billions of dollars.

The cost of an aircraft carrier can be broken down into several components, including the initial construction cost, operating costs, and maintenance costs. In this article, we will delve into the details of the costs associated with building and operating a US aircraft carrier, as well as explore the various factors that contribute to these costs.

Initial Construction Cost

The initial construction cost of an aircraft carrier is the largest single expense associated with these vessels. The cost of building a new aircraft carrier can range from $8 billion to $13 billion, depending on the size and complexity of the ship. The Gerald R. Ford-class aircraft carriers, for example, are estimated to cost around $13 billion each.

The construction cost includes the cost of materials, labor, and equipment, as well as the cost of designing and testing the ship. The cost of materials is a significant portion of the overall construction cost, with the ship's hull, engines, and flight deck requiring large amounts of steel, aluminum, and other materials.

Breakdown of Construction Costs

- Hull and propulsion: 30% of the total construction cost

- Flight deck and arresting gear: 20% of the total construction cost

- Electronics and communication systems: 15% of the total construction cost

- Aircraft and aviation systems: 10% of the total construction cost

- Miscellaneous (including labor and overhead): 25% of the total construction cost

Operating Costs

The operating costs of an aircraft carrier are significant, with the ship requiring a large crew and significant amounts of fuel to operate. The operating costs of an aircraft carrier can be broken down into several categories, including:

- Personnel costs: The salary and benefits of the crew, which can number over 5,000 personnel.

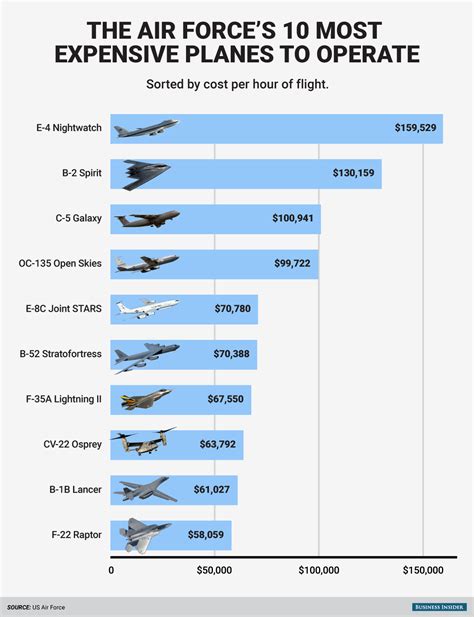

- Fuel costs: The cost of fuel for the ship's engines and aircraft.

- Maintenance costs: The cost of maintaining and repairing the ship and its systems.

- Supplies and services: The cost of food, medical supplies, and other services required to support the crew.

The operating costs of an aircraft carrier can range from $1 billion to $2 billion per year, depending on the ship's operational tempo and the cost of fuel.

Factors Affecting Operating Costs

- Crew size and composition: The number and type of personnel on board the ship can significantly affect operating costs.

- Operational tempo: The frequency and duration of deployments can impact fuel and maintenance costs.

- Fuel prices: The cost of fuel can fluctuate significantly, affecting the ship's operating costs.

Maintenance Costs

Maintenance costs are a significant portion of the overall cost of owning and operating an aircraft carrier. The ship's complex systems and equipment require regular maintenance to ensure they remain operational, and the cost of this maintenance can be substantial.

The maintenance costs of an aircraft carrier can be broken down into several categories, including:

- Routine maintenance: Regular maintenance tasks, such as cleaning and inspecting the ship's systems.

- Overhaul and repair: More extensive maintenance tasks, such as replacing or repairing major systems.

- Modernization: Upgrading the ship's systems and equipment to keep them current with the latest technology.

The maintenance costs of an aircraft carrier can range from $500 million to $1 billion per year, depending on the ship's age and operational tempo.

Factors Affecting Maintenance Costs

- Ship age: Older ships require more maintenance, as their systems and equipment become less reliable.

- Operational tempo: Ships that are deployed more frequently require more maintenance, as their systems and equipment are subjected to greater stress.

- Technology upgrades: Modernizing the ship's systems and equipment can reduce maintenance costs in the long run, but can be expensive upfront.

Conclusion

The cost of building and operating a US aircraft carrier is a significant expense, with the initial construction cost ranging from $8 billion to $13 billion and the operating costs ranging from $1 billion to $2 billion per year. Maintenance costs can add an additional $500 million to $1 billion per year. While these costs are significant, they are necessary to maintain the US Navy's power projection capabilities and ensure the country's national security.

Aircraft Carrier Image Gallery