Process capability indices, such as Cp and Cpk, are statistical measures used to evaluate the ability of a process to produce output within specified limits. In this article, we will explore how to calculate Cpk in Excel, providing a step-by-step guide.

Understanding Cpk

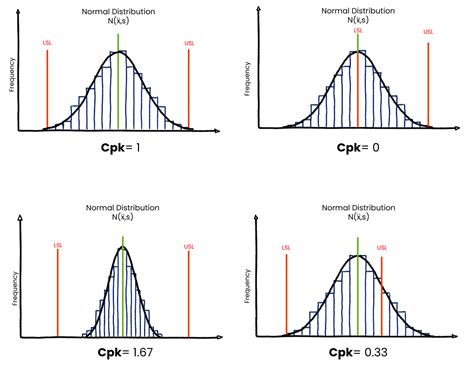

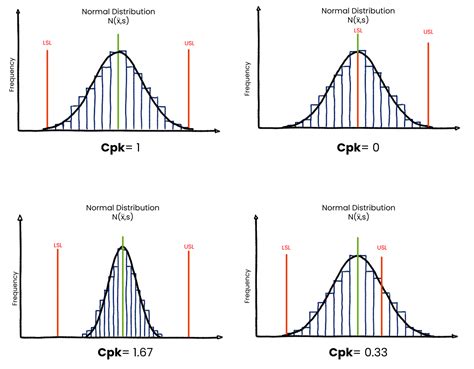

Cpk, or process capability index, measures the relationship between the natural variability of a process and the specifications imposed on the process. A high Cpk value indicates that the process is capable of producing output within the specified limits, while a low Cpk value indicates that the process may not be capable.

Why is Cpk important?

Cpk is an essential metric in quality control, as it helps manufacturers and engineers evaluate the performance of their processes. By calculating Cpk, organizations can:

- Identify processes that require improvement

- Evaluate the effectiveness of process changes

- Compare the performance of different processes

- Determine the probability of defects

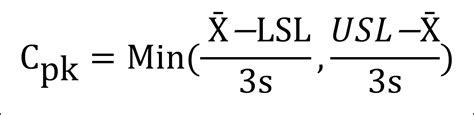

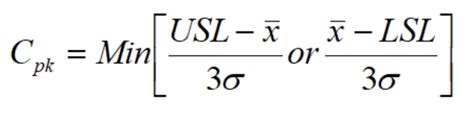

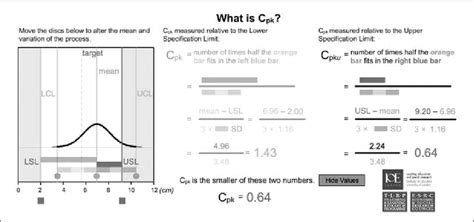

Cpk Calculation Formula

The Cpk formula is:

Cpk = min(USL - μ, μ - LSL) / (3 * σ)

Where:

- USL = Upper Specification Limit

- LSL = Lower Specification Limit

- μ = Process mean

- σ = Process standard deviation

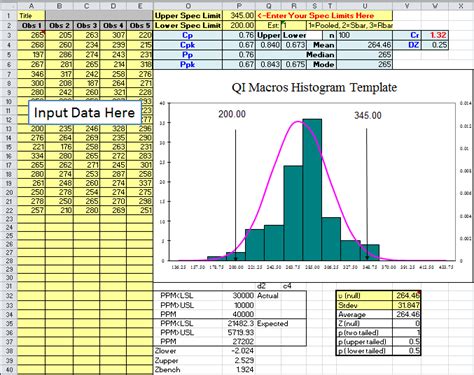

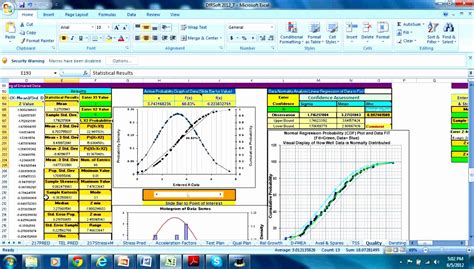

Calculating Cpk in Excel

To calculate Cpk in Excel, follow these steps:

- Collect data on the process output, including the measurements and specifications.

- Calculate the process mean (μ) using the AVERAGE function in Excel.

- Calculate the process standard deviation (σ) using the STDEV.S function in Excel.

- Determine the Upper Specification Limit (USL) and Lower Specification Limit (LSL) based on the specifications.

- Use the Cpk formula to calculate the Cpk value.

Here is an example of how to calculate Cpk in Excel:

| Measurement | Specification |

|---|---|

| 10.2 | 10.0 - 12.0 |

| 11.5 | 10.0 - 12.0 |

| 9.8 | 10.0 - 12.0 |

| 11.1 | 10.0 - 12.0 |

| 10.9 | 10.0 - 12.0 |

To calculate the process mean (μ), use the AVERAGE function:

=AVERAGE(B2:B6)

Output: 10.7

To calculate the process standard deviation (σ), use the STDEV.S function:

=STDEV.S(B2:B6)

Output: 0.55

To calculate the Cpk value, use the Cpk formula:

=MIN(12-10.7, 10.7-10)/(3*0.55)

Output: 1.35

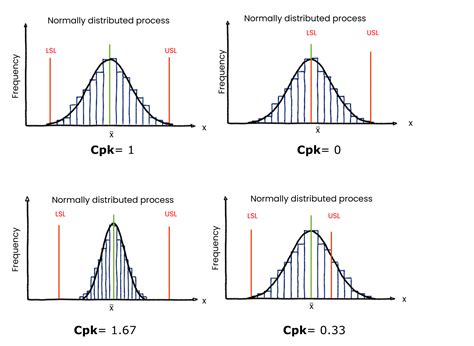

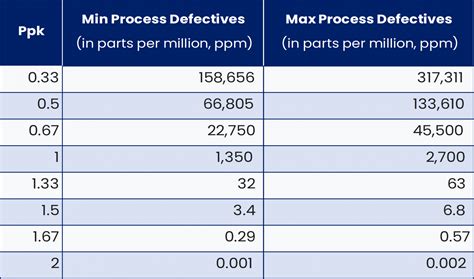

Interpreting Cpk Values

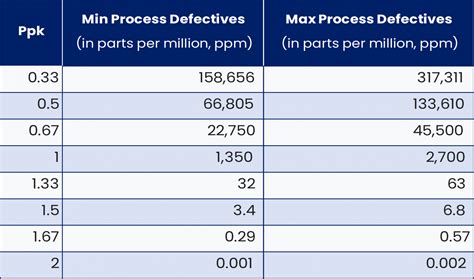

The Cpk value can be interpreted as follows:

- Cpk > 1.33: The process is capable of producing output within the specifications.

- Cpk = 1.00 - 1.33: The process is marginally capable of producing output within the specifications.

- Cpk < 1.00: The process is not capable of producing output within the specifications.

In this example, the Cpk value of 1.35 indicates that the process is capable of producing output within the specifications.

Common Challenges in Cpk Calculation

When calculating Cpk, there are several common challenges to consider:

- Non-normal data: If the data is not normally distributed, the Cpk calculation may not be accurate.

- Limited data: If there is limited data available, the Cpk calculation may not be reliable.

- Changing process conditions: If the process conditions change over time, the Cpk calculation may not reflect the current process performance.

To address these challenges, it is essential to:

- Verify the normality of the data using statistical tests

- Collect sufficient data to ensure reliable results

- Update the Cpk calculation regularly to reflect changes in process conditions

Best Practices for Cpk Calculation

To ensure accurate and reliable Cpk calculations, follow these best practices:

- Use robust statistical methods to verify the normality of the data

- Collect sufficient data to ensure reliable results

- Update the Cpk calculation regularly to reflect changes in process conditions

- Consider using alternative metrics, such as Ppk or Cpm, to supplement Cpk calculations

By following these best practices, organizations can ensure that their Cpk calculations are accurate, reliable, and actionable.

Gallery of Cpk Images

Cpk Image Gallery

Frequently Asked Questions (FAQs)

-

What is the difference between Cpk and Ppk? Cpk is a measure of process capability, while Ppk is a measure of process performance.

-

How do I calculate Cpk in Excel? Use the AVERAGE and STDEV.S functions to calculate the process mean and standard deviation, and then use the Cpk formula to calculate the Cpk value.

-

What is the minimum sample size required for Cpk calculation? The minimum sample size required for Cpk calculation is 30, but it is recommended to use a larger sample size for more reliable results.

-

Can I use Cpk to evaluate the performance of multiple processes? Yes, Cpk can be used to evaluate the performance of multiple processes and compare their capabilities.

-

What are some common challenges in Cpk calculation? Common challenges in Cpk calculation include non-normal data, limited data, and changing process conditions.

By following the steps outlined in this article, you can accurately calculate Cpk in Excel and improve the performance of your processes. Remember to consider the common challenges and best practices to ensure reliable and actionable results.