Intro

Master process control with the Cpk formula in Excel! Learn 5 practical ways to apply this powerful statistical tool to optimize your operations, including monitoring process variability, setting tolerance limits, and improving yield. Boost efficiency and accuracy with expert guidance on Cpk calculation, interpretation, and implementation in Excel.

In the world of process management and quality control, understanding the performance of a process is crucial. One widely used metric to evaluate process performance is the Process Capability Index, commonly referred to as Cpk. The Cpk formula is a statistical tool used to measure the ability of a process to produce output within specified limits. In this article, we will delve into the world of Cpk and explore five ways to use the Cpk formula in Excel.

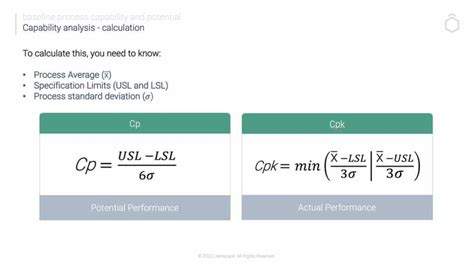

Process capability is a measure of the inherent variation of a process and its ability to produce output that meets specifications. The Cpk formula is one of the most commonly used metrics to evaluate process capability. It takes into account the mean and standard deviation of the process, as well as the specification limits.

What is Cpk Formula?

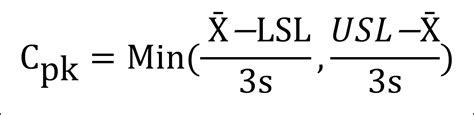

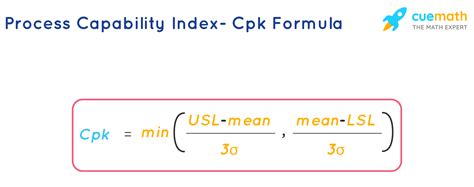

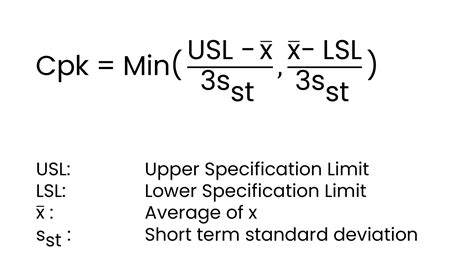

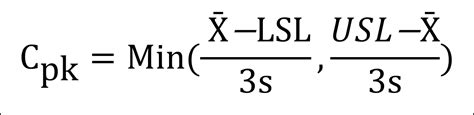

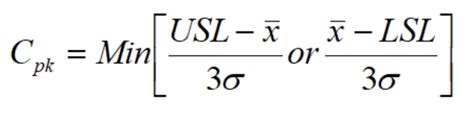

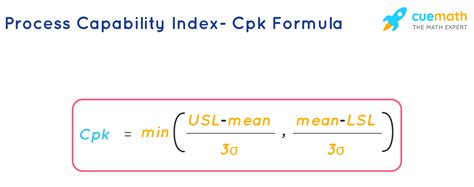

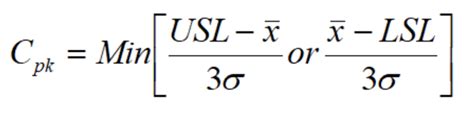

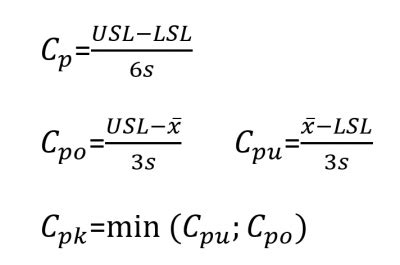

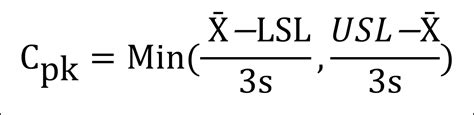

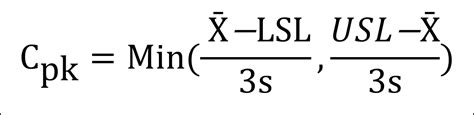

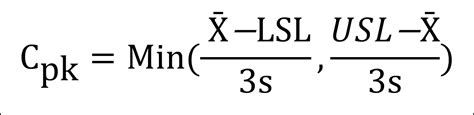

The Cpk formula is calculated using the following formula:

Cpk = min[(USL - μ) / (3σ), (μ - LSL) / (3σ)]

Where:

- Cpk = Process Capability Index

- USL = Upper Specification Limit

- LSL = Lower Specification Limit

- μ = Process Mean

- σ = Process Standard Deviation

Interpreting Cpk Values

Cpk values can be interpreted as follows:

- Cpk < 1: The process is not capable of producing output within specifications.

- Cpk = 1: The process is capable of producing output within specifications, but there is a high risk of defects.

- Cpk > 1: The process is capable of producing output within specifications, with a low risk of defects.

- Cpk ≥ 1.33: The process is considered to be capable and stable.

5 Ways to Use Cpk Formula in Excel

Now that we have a basic understanding of the Cpk formula, let's explore five ways to use it in Excel.

1. Calculating Cpk using the Cpk Formula

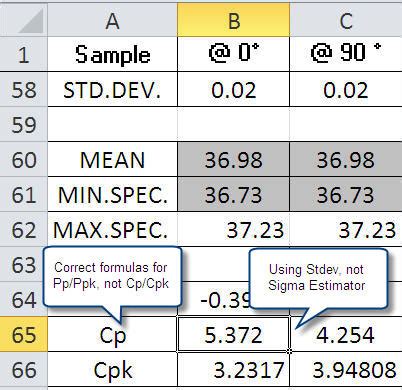

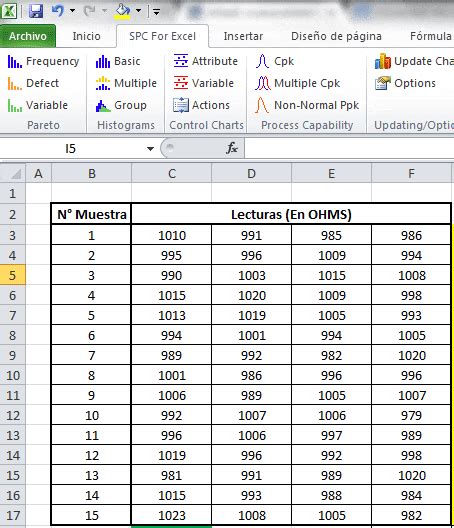

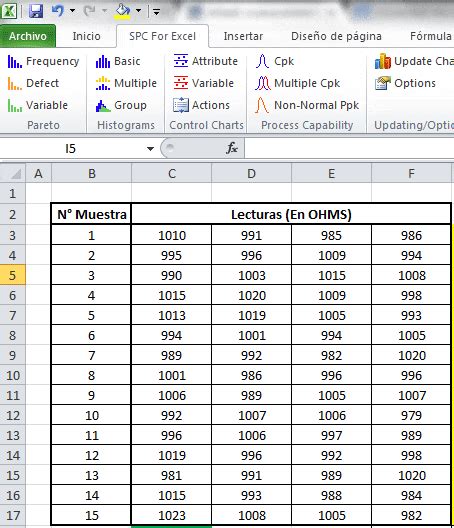

One of the most straightforward ways to use the Cpk formula in Excel is to calculate it manually. You can use the formula above and plug in the values for USL, LSL, μ, and σ.

2. Using Excel Functions to Calculate Cpk

Excel has several built-in functions that can be used to calculate Cpk. One of the most commonly used functions is the MIN function, which can be used to calculate the minimum of two values.

=Cpk = MIN((USL - μ) / (3σ), (μ - LSL) / (3σ))

3. Creating a Cpk Calculator Template

Another way to use the Cpk formula in Excel is to create a calculator template. This can be done by setting up a table with input fields for USL, LSL, μ, and σ, and then using formulas to calculate Cpk.

4. Using Excel Add-ins to Calculate Cpk

There are several Excel add-ins available that can be used to calculate Cpk. One of the most popular add-ins is the Analysis ToolPak, which includes a function for calculating process capability indices.

5. Automating Cpk Calculations using Macros

Finally, you can use Excel macros to automate Cpk calculations. This can be done by recording a macro that calculates Cpk using the formulas above, and then assigning the macro to a button or shortcut.

Gallery of Cpk Formula Images

In conclusion, the Cpk formula is a powerful tool for evaluating process capability and ensuring that output meets specifications. By using the five methods outlined above, you can easily calculate Cpk in Excel and make data-driven decisions to improve your processes.