Boost manufacturing efficiency with innovative assembly systems. Discover 5 ways to revolutionize production, from modular assembly lines to collaborative robotics, and unlock the full potential of Industry 4.0. Learn how to streamline workflows, reduce costs, and increase productivity with cutting-edge creative assembly solutions and smart factory technologies.

The manufacturing industry has undergone significant transformations over the years, driven by technological advancements and the need for increased efficiency. One key area that has seen substantial innovation is assembly systems. Traditional assembly lines, which were once the norm, are being replaced by more flexible and efficient creative assembly systems. These systems have revolutionized production in various industries, enabling companies to respond quickly to changing market demands, improve product quality, and reduce costs. In this article, we will explore five ways that creative assembly systems can revolutionize production.

Understanding Creative Assembly Systems

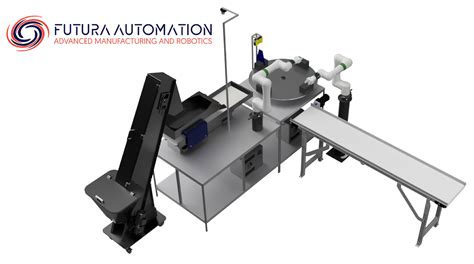

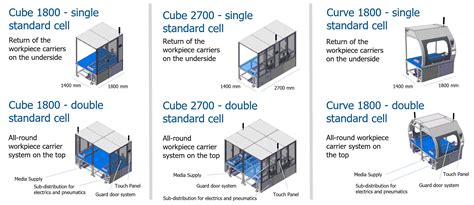

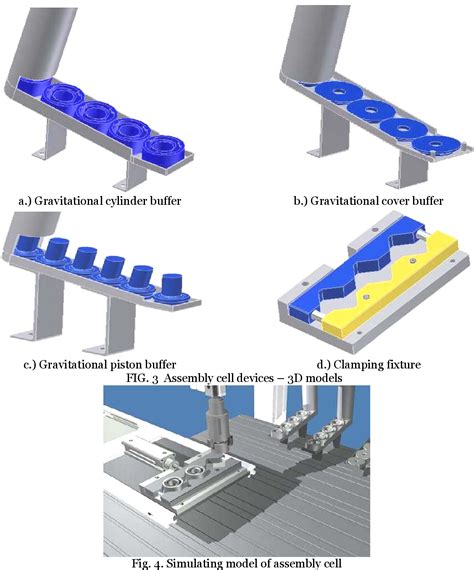

Creative assembly systems are designed to provide flexibility and adaptability in production processes. Unlike traditional assembly lines, which are often rigid and inflexible, creative assembly systems can be easily reconfigured to accommodate changes in product design or production volumes. This flexibility is achieved through the use of modular components, advanced robotics, and sophisticated software systems.

Key Characteristics of Creative Assembly Systems

- Modular design: Creative assembly systems are composed of interchangeable modules that can be easily rearranged to accommodate different products or production processes.

- Advanced robotics: Robotics play a key role in creative assembly systems, enabling the automation of complex tasks and improving overall efficiency.

- Sophisticated software: Advanced software systems are used to control and coordinate the various components of creative assembly systems, ensuring seamless integration and optimal performance.

5 Ways to Revolutionize Production with Creative Assembly Systems

1. Improved Flexibility and Adaptability

Creative assembly systems provide the flexibility and adaptability needed to respond quickly to changing market demands. With the ability to easily reconfigure production processes, companies can rapidly adapt to changes in product design, production volumes, or market trends. This flexibility enables companies to stay competitive in today's fast-paced and ever-changing market environment.

2. Increased Efficiency and Productivity

Creative assembly systems are designed to optimize production processes, resulting in significant gains in efficiency and productivity. Advanced robotics and sophisticated software systems work together to streamline production, reducing waste and minimizing downtime. This enables companies to produce more products in less time, resulting in increased productivity and competitiveness.

3. Enhanced Product Quality

Creative assembly systems are designed to ensure that products are manufactured to the highest standards of quality. Advanced inspection systems and quality control measures are integrated into the production process, ensuring that products meet or exceed customer expectations. This results in higher quality products, reduced waste, and increased customer satisfaction.

4. Reduced Labor Costs

Creative assembly systems can significantly reduce labor costs by automating complex tasks and streamlining production processes. Advanced robotics and automation systems can perform tasks that were previously done by humans, freeing up employees to focus on higher-value tasks. This results in reduced labor costs, improved productivity, and increased competitiveness.

5. Increased Sustainability

Creative assembly systems can help companies reduce their environmental footprint and improve sustainability. By optimizing production processes and reducing waste, companies can minimize their impact on the environment. Additionally, creative assembly systems can be designed to use renewable energy sources, reducing reliance on fossil fuels and promoting sustainability.

Implementing Creative Assembly Systems

Implementing creative assembly systems requires careful planning and execution. Companies must first assess their current production processes and identify areas for improvement. Next, they must design and configure the creative assembly system, taking into account the specific needs and requirements of their production processes. Finally, they must train employees and integrate the new system into their existing operations.

Best Practices for Implementing Creative Assembly Systems

- Conduct thorough assessments of current production processes to identify areas for improvement.

- Design and configure creative assembly systems that meet the specific needs and requirements of production processes.

- Train employees on the use and operation of creative assembly systems.

- Integrate creative assembly systems into existing operations, ensuring seamless integration and minimal disruption.

Creative Assembly Systems Image Gallery

We hope this article has provided valuable insights into the benefits of creative assembly systems and how they can revolutionize production in various industries. By implementing these systems, companies can improve flexibility and adaptability, increase efficiency and productivity, enhance product quality, reduce labor costs, and promote sustainability.