Intro

Boost performance with 5 CRN material tips, including corrosion resistance, nickel content, and chromium alloys for enhanced durability and strength in harsh environments.

The world of construction and manufacturing is constantly evolving, with new materials and technologies emerging all the time. One material that has gained significant attention in recent years is CRN, a type of steel alloy that offers a unique combination of strength, durability, and resistance to corrosion. If you're looking to work with CRN material, here are five tips to keep in mind.

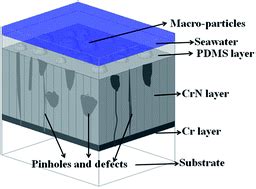

CRN material is a type of stainless steel alloy that contains a combination of chromium, nickel, and other elements. It is known for its excellent resistance to corrosion, high strength, and ability to withstand extreme temperatures. CRN material is commonly used in a variety of applications, including construction, manufacturing, and engineering. Whether you're building a new structure or repairing an existing one, CRN material is definitely worth considering.

One of the key benefits of CRN material is its versatility. It can be used in a wide range of applications, from building frames and structures to creating complex machinery and equipment. CRN material is also highly durable, able to withstand harsh weather conditions and heavy use without losing its strength or integrity. Additionally, CRN material is resistant to corrosion, making it an ideal choice for applications where exposure to water or moisture is a concern. With its unique combination of strength, durability, and resistance to corrosion, CRN material is an excellent choice for anyone looking to build or repair a structure that will last.

Understanding CRN Material Properties

Benefits of CRN Material

Some of the benefits of CRN material include: * High strength and durability * Resistance to corrosion and extreme temperatures * Versatility and ability to be used in a wide range of applications * High strength-to-weight ratio * Ability to withstand harsh weather conditions and heavy use CRN material is an excellent choice for anyone looking to build or repair a structure that will last. Its unique combination of strength, durability, and resistance to corrosion makes it an ideal choice for a wide range of applications, from construction and manufacturing to engineering and more.Working with CRN Material

CRN Material Applications

CRN material has a wide range of applications, including: * Construction and building * Manufacturing and engineering * Automotive and aerospace * Marine and offshore * Chemical and petrochemical CRN material is an excellent choice for any application where strength, durability, and resistance to corrosion are required. Its unique combination of properties makes it an ideal choice for a wide range of industries and applications.CRN Material Fabrication Techniques

CRN Material Safety Precautions

When working with CRN material, it's essential to follow proper safety precautions to avoid injury or damage. Some safety precautions to keep in mind include: * Wearing protective gear, such as gloves and safety glasses * Ensuring that the material is properly supported and handled during fabrication * Avoiding exposure to extreme temperatures or corrosive substances * Following proper welding and cutting techniques to avoid damaging the material By following these safety precautions, you can minimize the risk of injury or damage and ensure a successful fabrication process.CRN Material Maintenance and Repair

CRN Material Environmental Benefits

CRN material has a number of environmental benefits, including: * Reduced waste and pollution * Energy efficiency * Recyclability * Durability and longevity CRN material is an excellent choice for anyone looking to reduce their environmental impact. Its unique combination of properties makes it an ideal choice for a wide range of applications, from construction and manufacturing to engineering and more.CRN Material Cost and Availability

CRN Material Future Developments

The future of CRN material is exciting, with ongoing research and development aimed at improving its properties and applications. Some potential future developments for CRN material include: * Improved strength and durability * Enhanced resistance to corrosion and extreme temperatures * New fabrication techniques and technologies * Increased availability and reduced cost By staying up-to-date with the latest developments and advancements in CRN material, you can stay ahead of the curve and take advantage of its unique properties and benefits.CRN Material Gallery

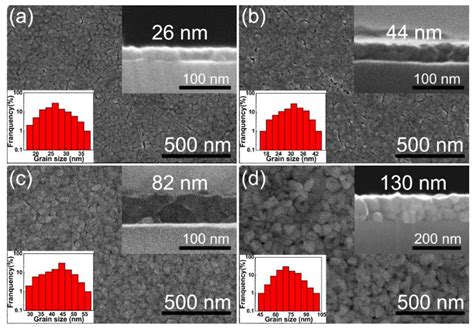

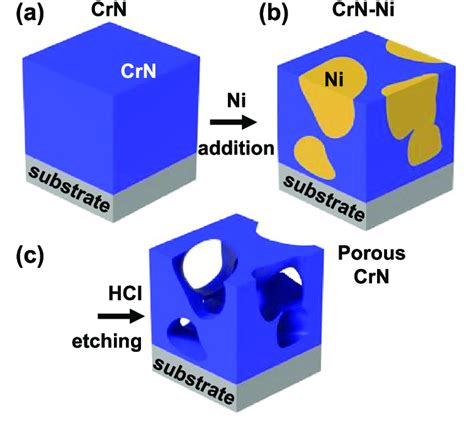

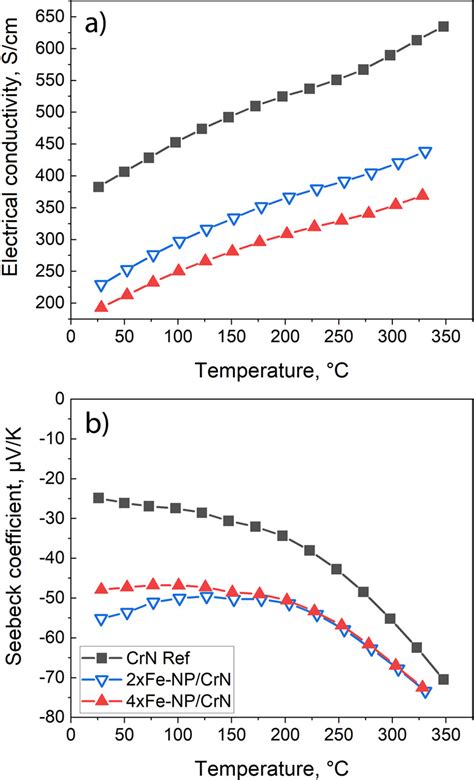

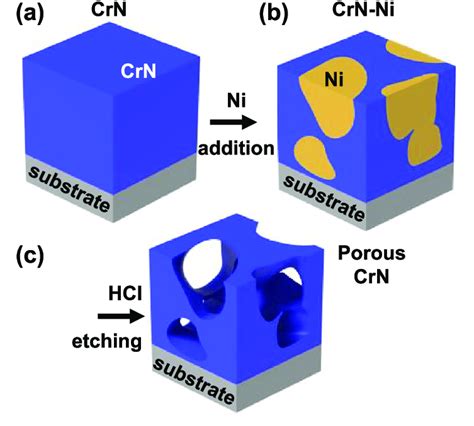

CRN Material Image Gallery

In conclusion, CRN material is a versatile and highly durable material that offers a unique combination of strength, durability, and resistance to corrosion. By understanding its properties, applications, and fabrication techniques, you can get the most out of CRN material and create strong, durable structures that will last. Whether you're working in construction, manufacturing, or engineering, CRN material is definitely worth considering. We invite you to share your thoughts and experiences with CRN material in the comments below, and don't forget to share this article with anyone who may be interested in learning more about this exciting material.