Discover the intricacies of development tank steel construction and fabrication. Learn about the design, engineering, and manufacturing process involved in building steel tanks for various industries. From material selection to welding techniques, understand the complexities and benefits of steel tank fabrication for efficient storage solutions.

The construction and fabrication of steel tanks are crucial for various industries such as oil and gas, chemical, water treatment, and food processing. Steel tanks are used to store a wide range of liquids and gases, and their development involves a combination of engineering, design, and manufacturing expertise. In this article, we will delve into the world of steel tank construction and fabrication, exploring the different types of tanks, the manufacturing process, and the key considerations for developers.

Types of Steel Tanks

Steel tanks come in a variety of shapes, sizes, and configurations, each designed for specific applications. Some of the most common types of steel tanks include:

- Vertical tanks: These tanks are designed for storing large quantities of liquids and are often used in the oil and gas industry.

- Horizontal tanks: These tanks are designed for storing smaller quantities of liquids and are often used in chemical processing and food processing.

- Rectangular tanks: These tanks are designed for storing large quantities of liquids and are often used in water treatment and wastewater management.

- Spherical tanks: These tanks are designed for storing liquefied gases and are often used in the oil and gas industry.

- Cylindrical tanks: These tanks are designed for storing large quantities of liquids and are often used in the chemical processing industry.

Manufacturing Process

The manufacturing process for steel tanks involves several stages, including:

- Design and engineering: The design and engineering stage involves creating detailed drawings and specifications for the tank, including the material selection, size, and configuration.

- Material selection: The material selection stage involves selecting the type of steel to be used for the tank, taking into account factors such as corrosion resistance, strength, and durability.

- Fabrication: The fabrication stage involves cutting, welding, and assembling the steel components into the desired shape and configuration.

- Welding: The welding stage involves joining the steel components together using specialized welding techniques and equipment.

- Inspection and testing: The inspection and testing stage involves checking the tank for any defects or imperfections and ensuring that it meets the required specifications.

Key Considerations for Developers

When developing a steel tank, there are several key considerations that must be taken into account, including:

- Safety: The safety of the tank and its contents is of paramount importance, and developers must ensure that the tank is designed and constructed to meet or exceed relevant safety standards.

- Corrosion resistance: Steel tanks are susceptible to corrosion, and developers must ensure that the tank is coated or lined with a corrosion-resistant material to prevent damage.

- Durability: Steel tanks must be designed and constructed to withstand the elements and last for many years, and developers must select materials and construction methods that ensure durability.

- Regulatory compliance: Steel tanks must comply with relevant regulations and standards, and developers must ensure that the tank meets or exceeds these requirements.

Steel Tank Construction Materials

The materials used for steel tank construction are critical to the tank's performance and durability. Some of the most common materials used for steel tank construction include:

- Carbon steel: Carbon steel is a popular choice for steel tank construction due to its strength, durability, and affordability.

- Stainless steel: Stainless steel is a corrosion-resistant material that is often used for steel tank construction in applications where corrosion is a concern.

- Aluminum: Aluminum is a lightweight and corrosion-resistant material that is often used for steel tank construction in applications where weight is a concern.

Steel Tank Fabrication Techniques

Steel tank fabrication involves several techniques, including:

- Welding: Welding is a critical technique used in steel tank fabrication to join the steel components together.

- Cutting: Cutting is used to cut the steel components to size and shape.

- Forming: Forming is used to shape the steel components into the desired configuration.

- Machining: Machining is used to finish the steel components and remove any imperfections.

Steel Tank Inspection and Testing

Steel tank inspection and testing are critical to ensuring the tank's safety and performance. Some of the most common inspection and testing methods used for steel tanks include:

- Visual inspection: Visual inspection involves a visual examination of the tank to identify any defects or imperfections.

- Non-destructive testing: Non-destructive testing involves using specialized equipment to test the tank without causing damage.

- Hydrostatic testing: Hydrostatic testing involves filling the tank with water to test its integrity.

Steel Tank Maintenance and Repair

Steel tank maintenance and repair are critical to extending the tank's lifespan and ensuring its safety and performance. Some of the most common maintenance and repair activities used for steel tanks include:

- Cleaning: Cleaning involves removing any debris or contaminants from the tank.

- Coating: Coating involves applying a protective coating to the tank to prevent corrosion.

- Welding: Welding involves repairing any defects or damage to the tank.

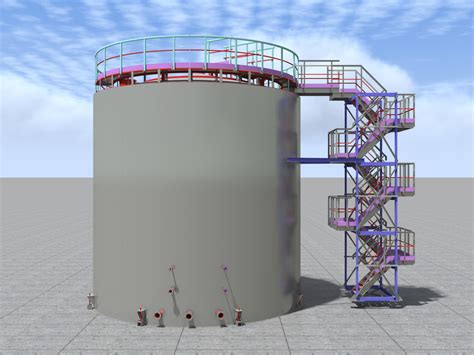

Steel Tank Construction Image Gallery

In conclusion, steel tank construction and fabrication involve a complex process that requires careful planning, design, and execution. By understanding the different types of steel tanks, the manufacturing process, and the key considerations for developers, we can ensure that steel tanks are constructed and fabricated to meet the required specifications and standards. We hope that this article has provided valuable insights into the world of steel tank construction and fabrication.