Intro

Boost equipment efficiency with a tailored Excel template. Discover 5 effective ways to track equipment maintenance, ensuring timely repairs and minimizing downtime. Learn how to create a customized template, set reminders, track history, and analyze performance using Excels powerful tools, optimizing your maintenance schedule and reducing costs.

Effective equipment maintenance is crucial for businesses that rely on machinery and equipment to operate efficiently. Regular maintenance helps prevent equipment breakdowns, reduces downtime, and saves costs. However, managing equipment maintenance can be a daunting task, especially for small to medium-sized businesses. Fortunately, using an Excel template can help simplify the process. Here are five ways to track equipment maintenance using an Excel template.

Benefits of Using an Excel Template for Equipment Maintenance

Before we dive into the ways to track equipment maintenance using an Excel template, let's explore the benefits of using a template:

- Easy to use and customize

- Cost-effective

- Scalable

- Improves organization and record-keeping

- Enhances data analysis and reporting

1. Create an Equipment Inventory List

To track equipment maintenance effectively, you need to have a comprehensive inventory list of all your equipment. An Excel template can help you create a list that includes the following information:

- Equipment name and description

- Serial number and model number

- Purchase date and warranty information

- Location and department responsible

- Maintenance schedule and history

Tips for Creating an Equipment Inventory List

- Use a separate sheet for each type of equipment

- Use filters and sorting to organize and analyze data

- Use conditional formatting to highlight equipment that requires maintenance

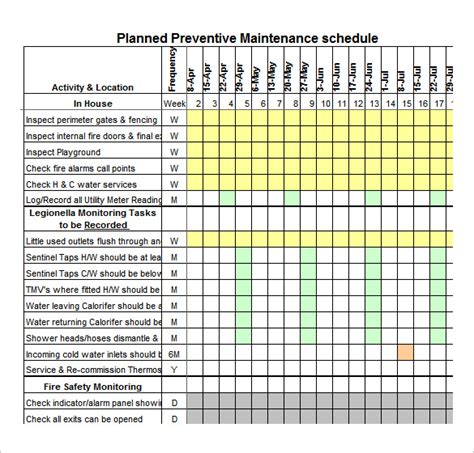

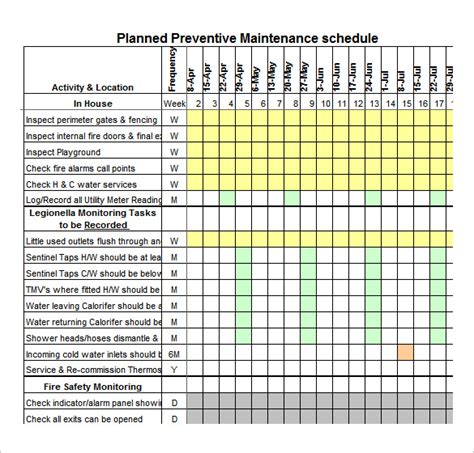

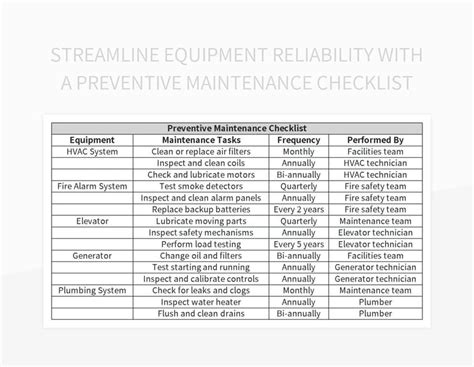

2. Develop a Preventive Maintenance Schedule

Preventive maintenance is essential to prevent equipment breakdowns and reduce downtime. An Excel template can help you develop a schedule that includes:

- Maintenance tasks and frequencies

- Due dates and reminders

- Responsible personnel and contact information

- Task status and completion dates

Tips for Developing a Preventive Maintenance Schedule

- Use a Gantt chart or calendar view to visualize the schedule

- Use formulas and functions to automate task assignments and due dates

- Use conditional formatting to highlight overdue tasks

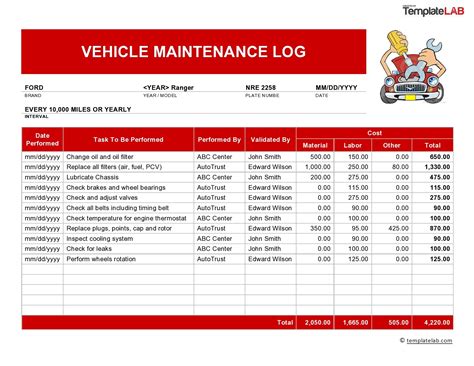

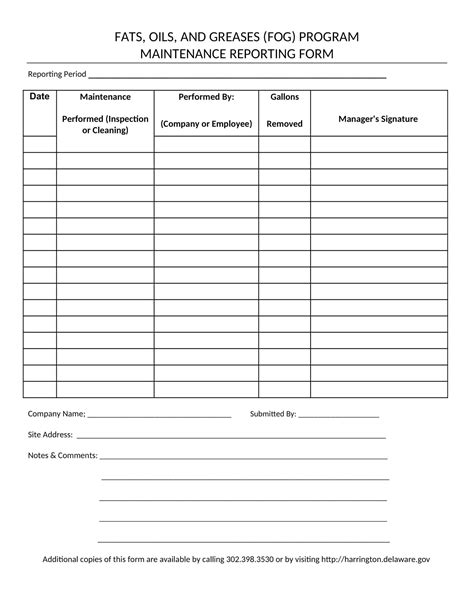

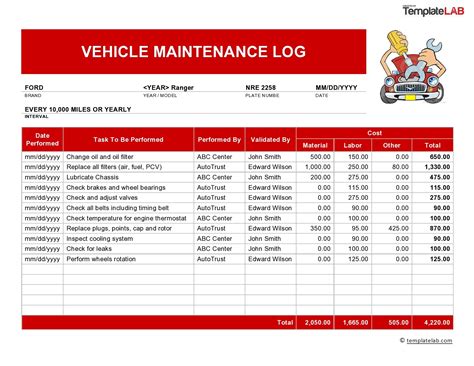

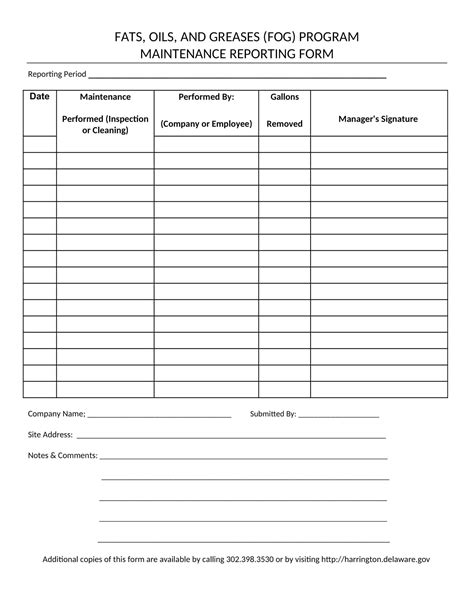

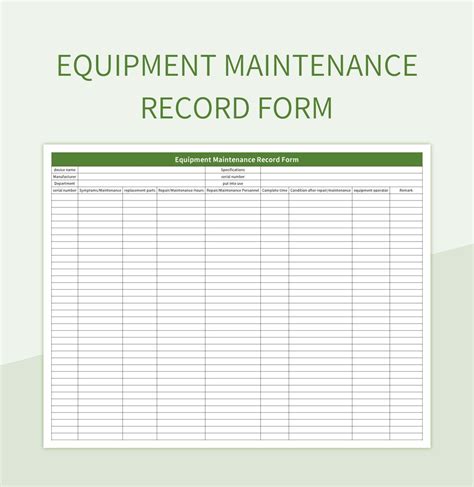

3. Track Maintenance History and Records

Tracking maintenance history and records is crucial to identify trends and patterns in equipment performance. An Excel template can help you track:

- Maintenance tasks and activities

- Dates and times of maintenance

- Personnel involved and contact information

- Parts and materials used

- Costs and expenses

Tips for Tracking Maintenance History and Records

- Use a separate sheet for each equipment item

- Use filters and sorting to organize and analyze data

- Use pivot tables to summarize and visualize data

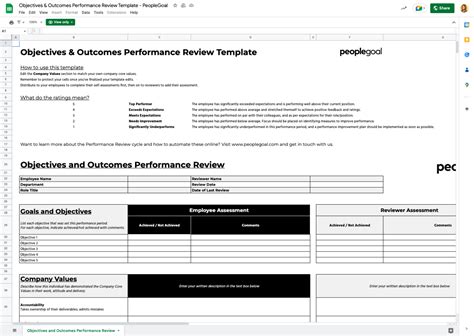

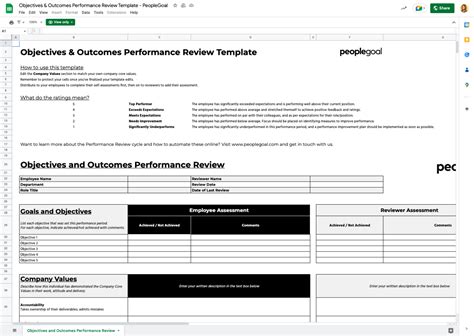

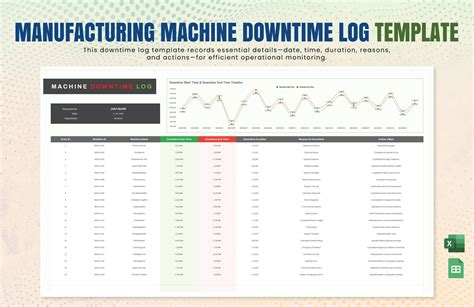

4. Analyze Equipment Performance and Reliability

Analyzing equipment performance and reliability helps identify areas for improvement and optimize maintenance strategies. An Excel template can help you analyze:

- Equipment uptime and downtime

- Mean time between failures (MTBF) and mean time to repair (MTTR)

- Maintenance costs and expenses

- Reliability and availability metrics

Tips for Analyzing Equipment Performance and Reliability

- Use formulas and functions to calculate metrics and KPIs

- Use charts and graphs to visualize data and trends

- Use conditional formatting to highlight areas for improvement

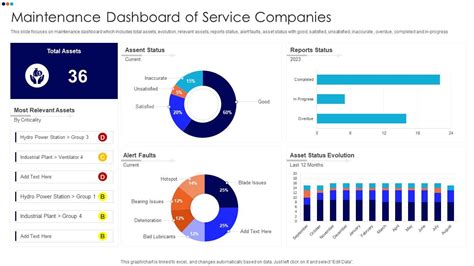

5. Generate Reports and Dashboards

Generating reports and dashboards helps stakeholders and decision-makers understand equipment maintenance performance and make informed decisions. An Excel template can help you generate:

- Summary reports and dashboards

- Detailed reports and analysis

- Ad-hoc reports and queries

Tips for Generating Reports and Dashboards

- Use pivot tables and charts to summarize and visualize data

- Use conditional formatting to highlight key performance indicators (KPIs)

- Use formulas and functions to automate report generation

Equipment Maintenance Template Gallery

By following these five ways to track equipment maintenance using an Excel template, you can improve your maintenance strategies, reduce downtime, and increase equipment reliability. Remember to customize your template to fit your specific needs and requirements.

We hope this article has provided you with valuable insights and practical tips on how to track equipment maintenance using an Excel template. If you have any questions or need further assistance, please don't hesitate to comment below.