Intro

Discover the ultimate guide to creating an Excel Bill of Materials (BOM) with 7 actionable methods. Learn how to streamline your inventory management, improve project planning, and enhance collaboration with a well-structured BOM. Explore tips on data organization, formula optimization, and visualization to boost efficiency and accuracy in your Excel BOM.

In the world of manufacturing, engineering, and construction, a Bill of Materials (BOM) is a crucial document that outlines the components, materials, and quantities required to create a product or complete a project. An Excel Bill of Materials is a popular tool used to create and manage BOMs efficiently. In this article, we will explore 7 ways to create an Excel Bill of Materials.

Why Use Excel for Bill of Materials?

Before we dive into the methods, let's quickly discuss why Excel is a popular choice for creating BOMs. Excel offers several benefits, including:

- Easy data management and manipulation

- Flexibility in formatting and customization

- Calculations and formulas for automatic quantity and cost updates

- Collaboration and sharing capabilities

- Compatibility with other Microsoft Office tools

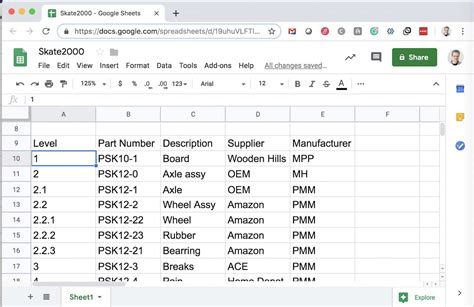

Method 1: Manual Entry

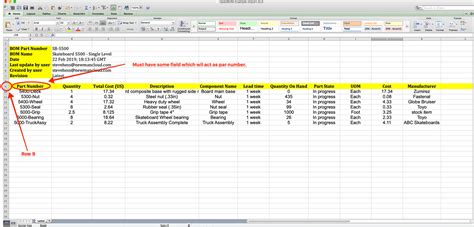

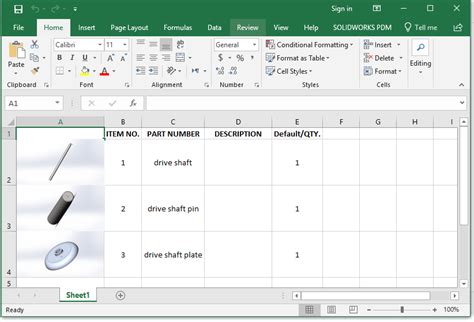

The most straightforward way to create an Excel Bill of Materials is to manually enter the data into a spreadsheet. This method involves creating a table with columns for component names, descriptions, quantities, and costs.

Method 2: Using Excel Templates

Another way to create an Excel Bill of Materials is to use pre-built templates. Microsoft Excel offers several free templates for BOMs, which can be downloaded and customized to suit your needs.

Method 3: Importing Data from Other Sources

If you have existing data in other formats, such as CSV or JSON files, you can import it into Excel to create a BOM. This method is useful when working with large datasets or integrating data from multiple sources.

Method 4: Using Excel Formulas and Functions

Excel formulas and functions can be used to automate calculations and updates in your BOM. For example, you can use the SUM function to calculate the total cost of materials or the VLOOKUP function to retrieve component information from other tables.

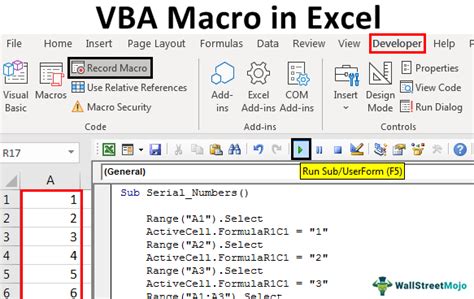

Method 5: Creating a BOM with Excel Macros

If you need to create a complex BOM with custom logic and automation, you can use Excel macros. Macros are programmed scripts that can perform tasks, such as data manipulation and formatting, with a single click.

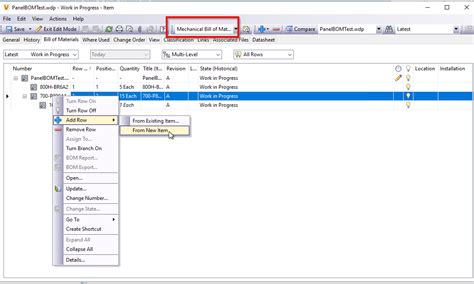

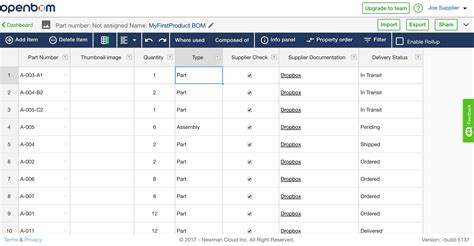

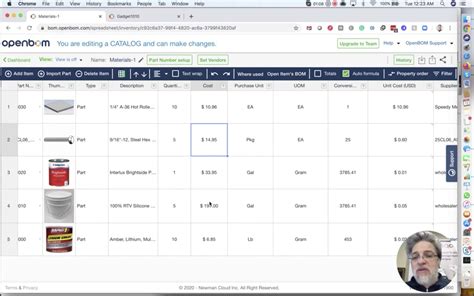

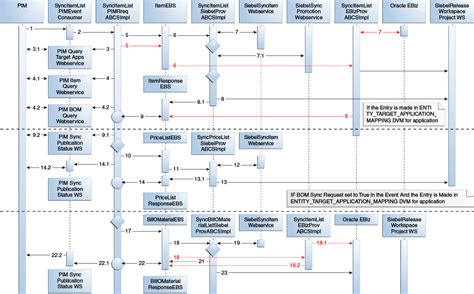

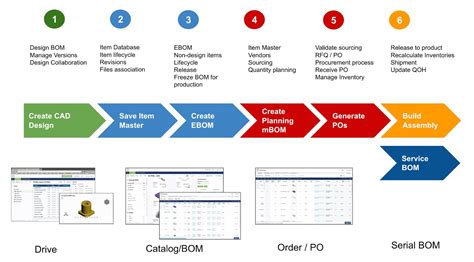

Method 6: Integrating with Other Tools and Software

Excel can be integrated with other tools and software, such as ERP systems, CAD software, and project management tools, to create a seamless BOM creation and management process.

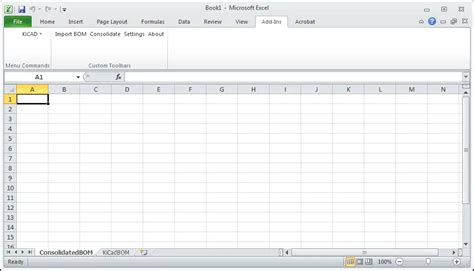

Method 7: Using Excel Add-ins and Plug-ins

Several Excel add-ins and plug-ins are available that can help you create and manage BOMs efficiently. These add-ins can provide additional features, such as automated data entry, advanced calculations, and customized reporting.

Best Practices for Creating an Excel Bill of Materials

When creating an Excel Bill of Materials, keep the following best practices in mind:

- Use clear and concise formatting and labeling

- Organize data into logical tables and sections

- Use formulas and functions to automate calculations and updates

- Regularly review and update the BOM to ensure accuracy and relevance

- Consider using add-ins and plug-ins to enhance functionality

Common Challenges and Solutions

When working with Excel BOMs, you may encounter challenges, such as data inconsistencies, calculation errors, and collaboration issues. To overcome these challenges, consider the following solutions:

- Use data validation and formatting rules to ensure data consistency

- Use error-checking formulas and functions to detect and correct calculation errors

- Use collaboration tools, such as Excel Online or SharePoint, to facilitate team collaboration and feedback

Conclusion

Creating an Excel Bill of Materials can be a straightforward process, and the methods outlined in this article can help you get started. By following best practices and using the right tools and techniques, you can create an accurate and effective BOM that streamlines your manufacturing, engineering, or construction project.

Gallery of Excel Bill of Materials Examples

Excel Bill of Materials Examples

We hope this article has provided you with a comprehensive guide to creating an Excel Bill of Materials. Share your experiences, tips, and best practices in the comments below!