Intro

Streamline equipment upkeep with our Excel preventive maintenance template. Easily schedule tasks, track maintenance records, and reduce downtime. Learn how to create a customized template, implement a PM schedule, and optimize your maintenance routine using key performance indicators (KPIs) and condition-based monitoring.

Effective preventive maintenance is crucial for ensuring the smooth operation of equipment, machinery, and facilities. A well-planned preventive maintenance schedule can help prevent unexpected breakdowns, reduce downtime, and lower maintenance costs. One of the most efficient ways to create and manage a preventive maintenance schedule is by using an Excel preventive maintenance template. In this article, we will explore the benefits of using an Excel template for preventive maintenance and provide a step-by-step guide on how to create and use one.

Benefits of Using an Excel Preventive Maintenance Template

Using an Excel preventive maintenance template offers numerous benefits, including:

- Improved organization: An Excel template helps you to organize and prioritize maintenance tasks, ensuring that everything runs smoothly and efficiently.

- Increased productivity: By scheduling maintenance tasks in advance, you can reduce downtime and increase productivity.

- Cost savings: Preventive maintenance can help reduce maintenance costs by identifying and addressing potential issues before they become major problems.

- Enhanced safety: Regular maintenance can help prevent accidents and ensure a safe working environment.

Key Components of an Excel Preventive Maintenance Template

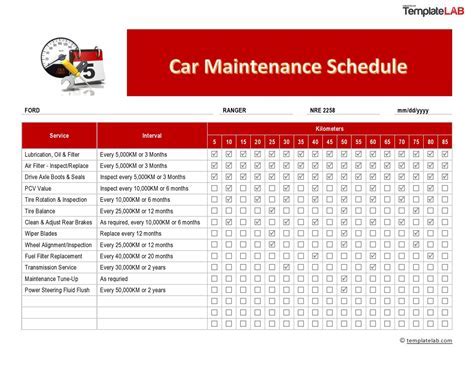

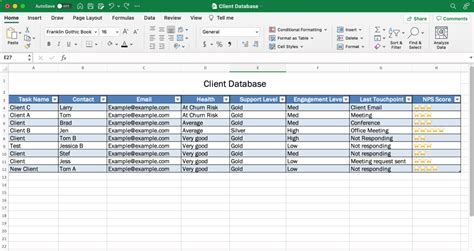

A typical Excel preventive maintenance template should include the following key components:

- Equipment/Machinery List: A list of all equipment and machinery that require regular maintenance.

- Maintenance Schedule: A calendar-based schedule that outlines the frequency and due dates of maintenance tasks.

- Task List: A detailed list of maintenance tasks, including descriptions, frequencies, and responsible personnel.

- Tracking and Reporting: A system for tracking and reporting maintenance activities, including completion dates, notes, and comments.

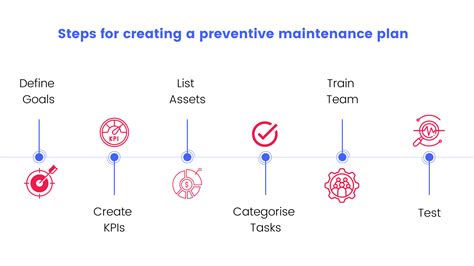

Creating an Excel Preventive Maintenance Template

Creating an Excel preventive maintenance template is a straightforward process. Here's a step-by-step guide to help you get started:

- Set up a new Excel spreadsheet: Create a new Excel spreadsheet and give it a descriptive title, such as "Preventive Maintenance Schedule."

- Create a equipment/machinery list: Create a table to list all equipment and machinery that require regular maintenance. Include columns for equipment name, description, and location.

- Create a maintenance schedule: Create a calendar-based schedule that outlines the frequency and due dates of maintenance tasks. Use Excel's built-in calendar functions to create a schedule that spans multiple months or years.

- Create a task list: Create a detailed list of maintenance tasks, including descriptions, frequencies, and responsible personnel.

- Set up tracking and reporting: Create a system for tracking and reporting maintenance activities, including completion dates, notes, and comments.

Example of an Excel Preventive Maintenance Template

Here's an example of what an Excel preventive maintenance template might look like:

| Equipment Name | Description | Location | Maintenance Frequency | Due Date |

|---|---|---|---|---|

| Pump 1 | Centrifugal pump | Warehouse | Monthly | 2023-02-15 |

| Pump 2 | Positive displacement pump | Warehouse | Quarterly | 2023-03-15 |

| Air Compressor | Reciprocating air compressor | Factory floor | Semi-annually | 2023-06-15 |

Using an Excel Preventive Maintenance Template

Using an Excel preventive maintenance template is easy. Here are some tips to get you started:

- Regularly review and update the schedule: Regularly review and update the maintenance schedule to ensure that all tasks are completed on time.

- Assign tasks to personnel: Assign maintenance tasks to responsible personnel to ensure that everything gets done.

- Track and report progress: Use the template to track and report progress, including completion dates, notes, and comments.

Best Practices for Using an Excel Preventive Maintenance Template

Here are some best practices to keep in mind when using an Excel preventive maintenance template:

- Keep it simple: Keep the template simple and easy to use.

- Use clear and concise language: Use clear and concise language to describe maintenance tasks and frequencies.

- Regularly review and update: Regularly review and update the template to ensure that it remains relevant and effective.

Conclusion

An Excel preventive maintenance template is a powerful tool for ensuring the smooth operation of equipment, machinery, and facilities. By following the steps outlined in this article, you can create and use a template that meets your specific needs and helps you to reduce downtime, lower maintenance costs, and improve overall productivity.

Preventive Maintenance Image Gallery