Inspecting Navy warships reveals faulty welds, putting national security at risk. Welding defects compromise shipbuilding quality, threatening crew safety and vessel integrity. Discover how inadequate welding practices, corrosion, and inspection failures contribute to this critical issue, impacting naval readiness and prompting urgent reform in shipbuilding and repair procedures.

The United States Navy has long been a symbol of power and strength, with its warships serving as a testament to the country's military prowess. However, recent revelations have raised concerns about the structural integrity of these vessels, specifically regarding faulty welds that could put the entire fleet at risk.

The importance of welds in shipbuilding cannot be overstated. Welds are used to join metal components together, creating a strong and durable bond that is essential for withstanding the stresses of the high seas. However, if these welds are not done correctly, they can lead to catastrophic failures that put the entire ship and its crew in danger. This is precisely what has been discovered in several Navy warships, including the USS Zumwalt and the USS Monsoor.

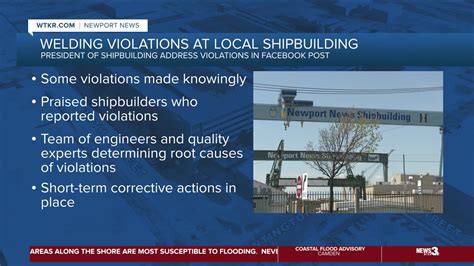

The USS Zumwalt, a cutting-edge destroyer, has been plagued by welding issues since its construction. In 2016, it was discovered that the ship's builder, Bath Iron Works, had used a welding technique that did not meet Navy standards. This led to a host of problems, including cracks in the ship's hull and a compromised propulsion system.

Similarly, the USS Monsoor, a San Antonio-class amphibious transport dock, has also been found to have faulty welds. In 2019, an investigation revealed that the ship's builder, Ingalls Shipbuilding, had used a substandard welding technique that put the ship's structural integrity at risk.

These incidents have raised serious concerns about the quality control measures in place at Navy shipyards. If faulty welds are not detected and corrected, they can lead to a range of problems, including leaks, corrosion, and even complete structural failure.

Causes of Faulty Welds

So, what causes faulty welds in the first place? There are several factors that can contribute to substandard welding, including:

-

Lack of Training

One of the primary causes of faulty welds is a lack of proper training for welders. If welders are not adequately trained, they may not have the necessary skills to perform high-quality welds.

-

Inadequate Quality Control

Another factor that can contribute to faulty welds is inadequate quality control measures. If shipbuilders do not have robust quality control processes in place, they may not detect substandard welds until it's too late.

-

Pressure to Meet Deadlines

The pressure to meet deadlines can also lead to faulty welds. If shipbuilders are rushing to complete a project, they may be tempted to cut corners and sacrifice quality for speed.

Consequences of Faulty Welds

The consequences of faulty welds can be severe. If a ship's structural integrity is compromised, it can lead to a range of problems, including:

-

Leaks and Corrosion

Leaks and corrosion can occur if faulty welds allow water to seep into the ship's hull. This can lead to costly repairs and even put the ship's crew at risk.

-

Structural Failure

In extreme cases, faulty welds can lead to complete structural failure. This can result in catastrophic consequences, including the loss of the ship and its crew.

-

Costly Repairs

Faulty welds can also lead to costly repairs. If a ship's welds are not done correctly, it can require significant repairs, which can be time-consuming and expensive.

Solutions to Faulty Welds

So, what can be done to prevent faulty welds in Navy warships? There are several solutions that can be implemented, including:

-

Improved Training

Providing welders with improved training can help to ensure that they have the necessary skills to perform high-quality welds.

-

Robust Quality Control

Implementing robust quality control measures can help to detect substandard welds before they become a problem.

-

Regular Inspections

Regular inspections can help to detect faulty welds before they cause serious problems.

Conclusion

Faulty welds in Navy warships are a serious concern that can put the entire fleet at risk. By understanding the causes of faulty welds and implementing solutions to prevent them, we can help to ensure the structural integrity of our warships and keep our sailors safe.

We invite you to share your thoughts on this issue. Have you or someone you know been affected by faulty welds in a Navy warship? What do you think can be done to prevent this problem in the future? Share your comments below.

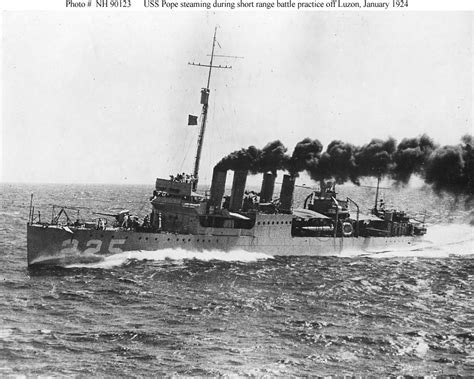

Navy Warships Faulty Welds Image Gallery