Intro

Flange sizes are a crucial aspect of piping systems, and having a comprehensive understanding of their dimensions is vital for ensuring the safe and efficient operation of various industrial processes. A flange size chart is an essential tool for engineers, technicians, and other professionals working with piping systems, as it provides a quick and easy reference for determining the correct flange size for a particular application.

Understanding Flange Sizes

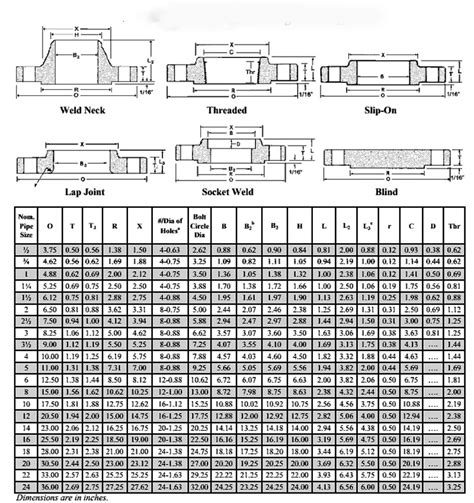

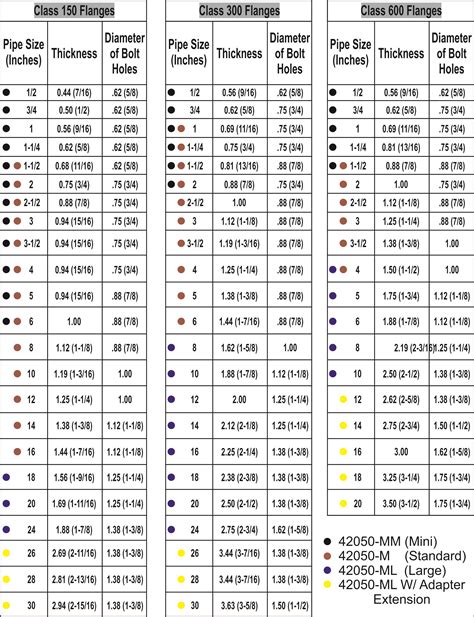

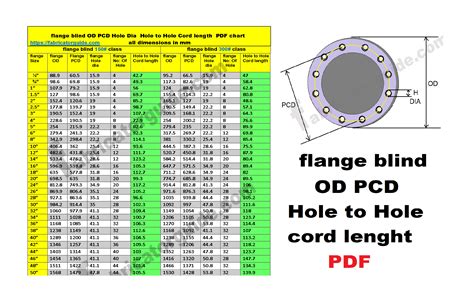

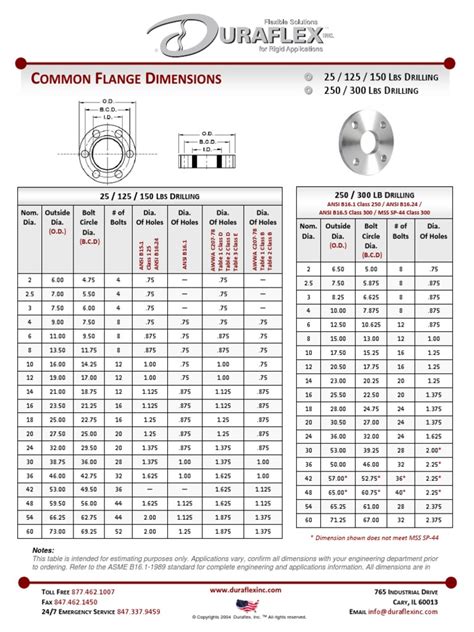

Flanges are used to connect pipes, valves, and other equipment in a piping system, and they come in a wide range of sizes to accommodate different pipe sizes and types. The size of a flange is typically measured in terms of its nominal pipe size (NPS), which is the diameter of the pipe in inches. However, the actual size of the flange can vary depending on the type of flange, the material it is made of, and the pressure rating of the system.

Flange Size Chart Types

There are several types of flange size charts available, including:

- ANSI (American National Standards Institute) flange size charts

- API (American Petroleum Institute) flange size charts

- ASME (American Society of Mechanical Engineers) flange size charts

- DIN (Deutsches Institut für Normung) flange size charts

Each of these charts provides a comprehensive guide to flange sizes, including dimensions, pressure ratings, and material specifications.

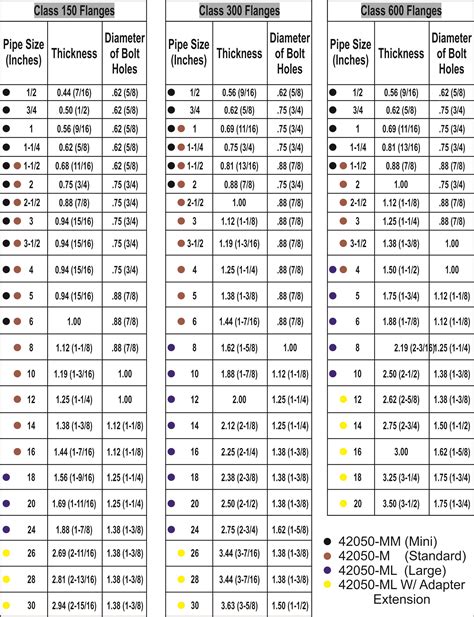

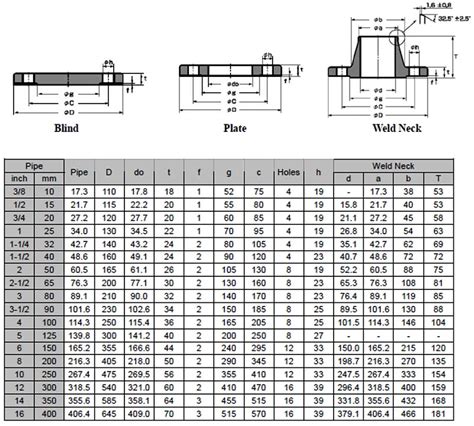

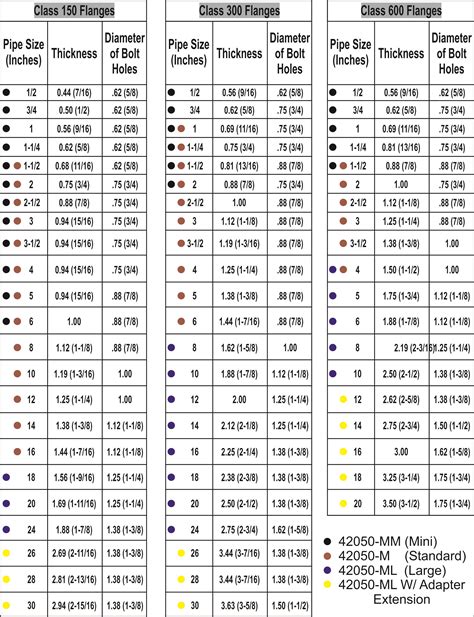

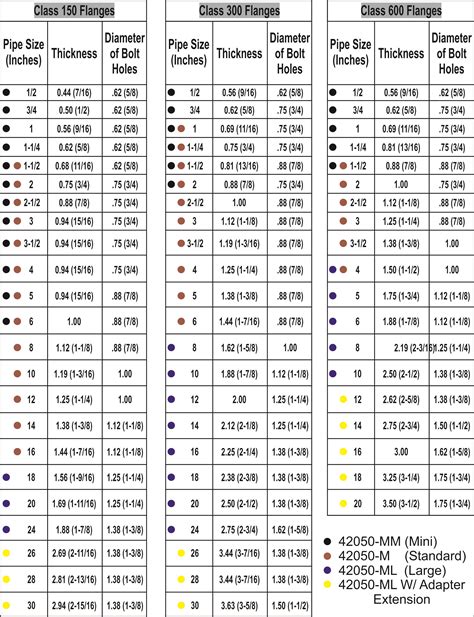

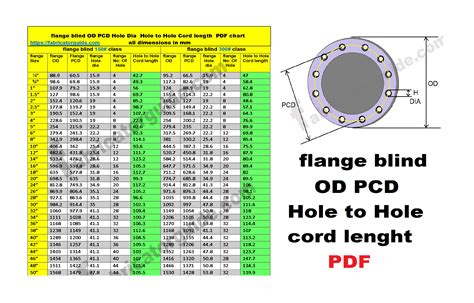

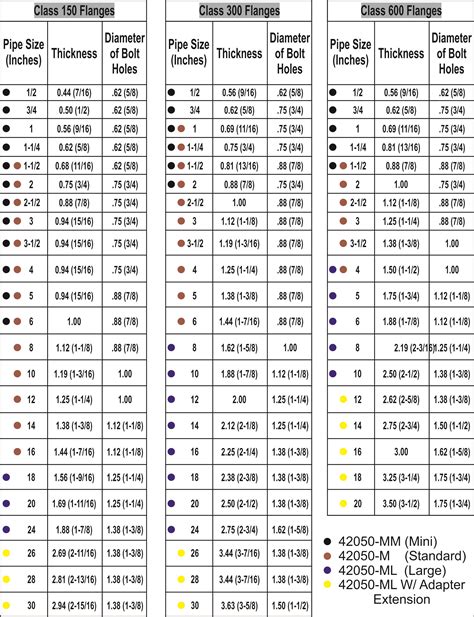

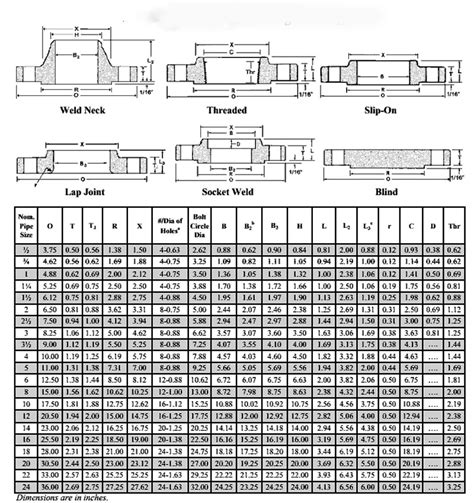

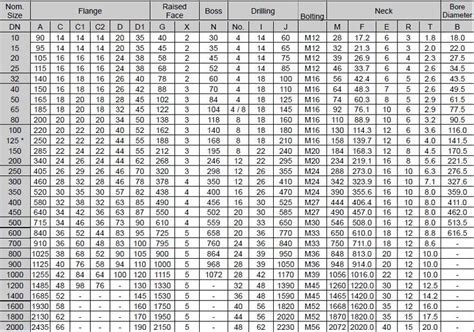

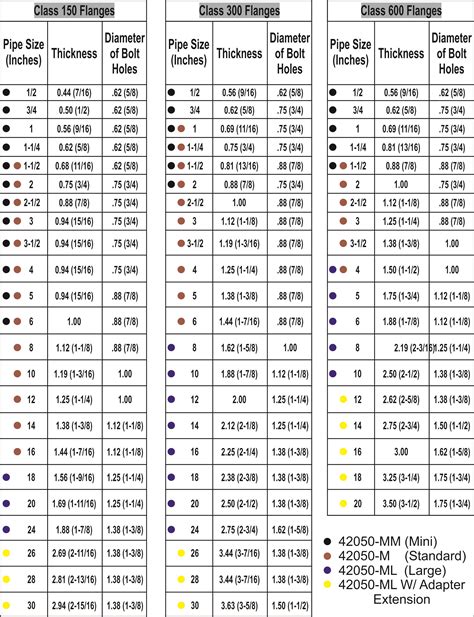

Flange Size Chart Dimensions

The dimensions of a flange size chart typically include:

- Flange outside diameter (OD)

- Flange inside diameter (ID)

- Bolt circle diameter (BCD)

- Number of bolts

- Bolt size

- Pressure rating

These dimensions are critical for ensuring that the flange is properly sized for the piping system and that it can withstand the operating pressures and temperatures.

Flange Size Chart Pressure Ratings

Flange size charts also provide information on pressure ratings, which are critical for ensuring the safe operation of the piping system. Pressure ratings are typically expressed in terms of pounds per square inch (PSI) or bars, and they vary depending on the type of flange, the material it is made of, and the temperature of the system.

Using a Flange Size Chart

Using a flange size chart is a straightforward process that involves the following steps:

- Determine the nominal pipe size (NPS) of the pipe.

- Select the type of flange and material.

- Determine the pressure rating of the system.

- Consult the flange size chart to determine the correct flange size.

- Verify the dimensions and pressure rating of the flange.

Flange Size Chart Printable Guide

A flange size chart printable guide is a convenient and portable resource that provides a comprehensive guide to flange sizes. These guides are typically available in PDF format and can be printed out for easy reference.

Benefits of Using a Flange Size Chart

Using a flange size chart provides several benefits, including:

- Ensuring accurate sizing of flanges for piping systems

- Reducing the risk of errors and omissions

- Improving safety and efficiency of piping systems

- Providing a quick and easy reference for flange sizes and dimensions

Common Applications of Flange Size Charts

Flange size charts are commonly used in a variety of industries, including:

- Oil and gas

- Chemical processing

- Power generation

- Water treatment

- Food processing

These charts are essential for ensuring the safe and efficient operation of piping systems in these industries.

Flange Size Chart Image Gallery

We hope this article has provided a comprehensive guide to flange size charts and their importance in piping systems. If you have any questions or need further clarification, please don't hesitate to comment below.