Intro

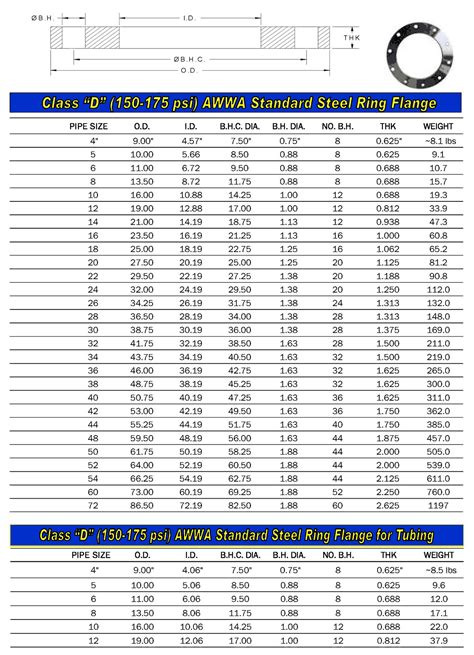

Boost your piping projects with these 7 essential flange size charts. Get instant access to printable charts for ASA, BS, DIN, and more. Master flange dimensions, from Class 150 to 2500, and improve your workflow with our comprehensive guide, featuring Pressure Class, Temperature, and piping codes for precise installation.

Having the right tools and resources on hand can make all the difference in ensuring a smooth and efficient workflow. When it comes to working with pipes and fittings, one of the most essential resources is a reliable flange size chart. In this article, we will explore the importance of flange size charts and provide you with 7 essential charts to print now.

The importance of flange size charts cannot be overstated. Flanges are a critical component of piping systems, used to connect and disconnect pipes, valves, and other equipment. With so many different types and sizes of flanges available, it can be challenging to ensure that you have the right size and type of flange for your specific application. This is where a flange size chart comes in handy.

A flange size chart provides a quick and easy reference guide for determining the correct size and type of flange needed for a particular application. By having a chart on hand, you can quickly and accurately identify the correct flange size, saving you time and reducing the risk of errors.

In the following sections, we will explore 7 essential flange size charts that you can print now and keep on hand for future reference.

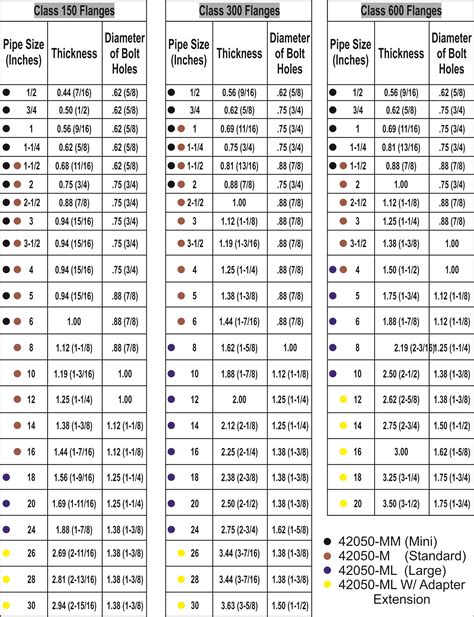

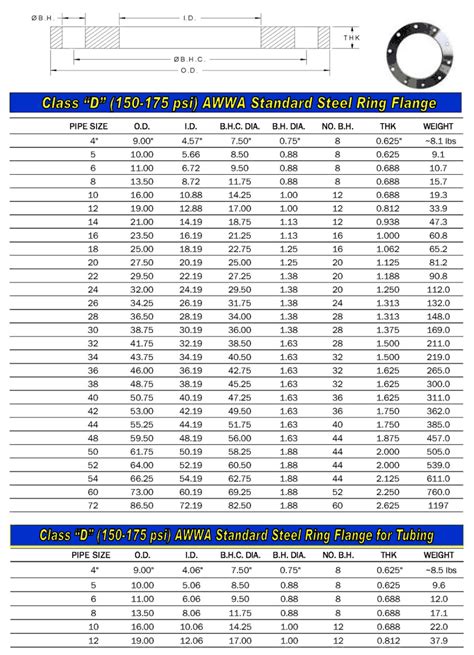

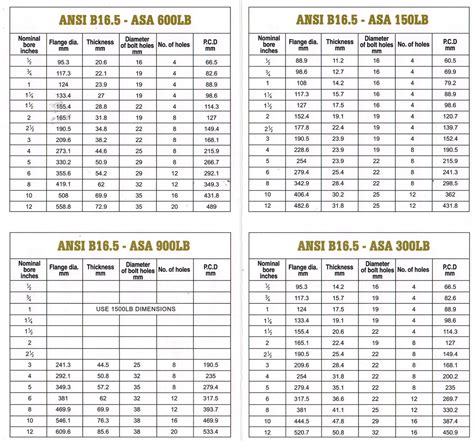

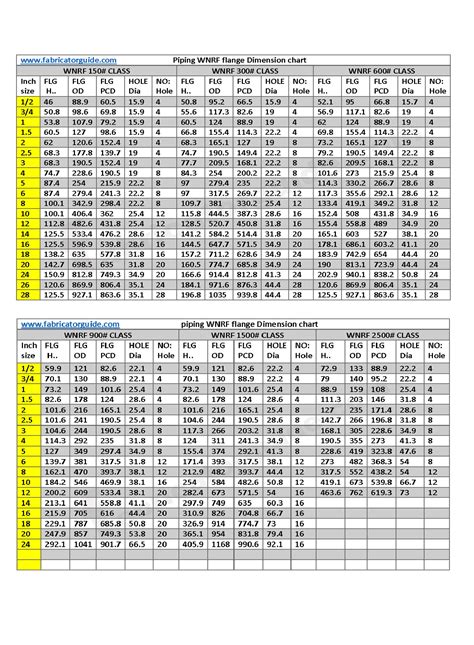

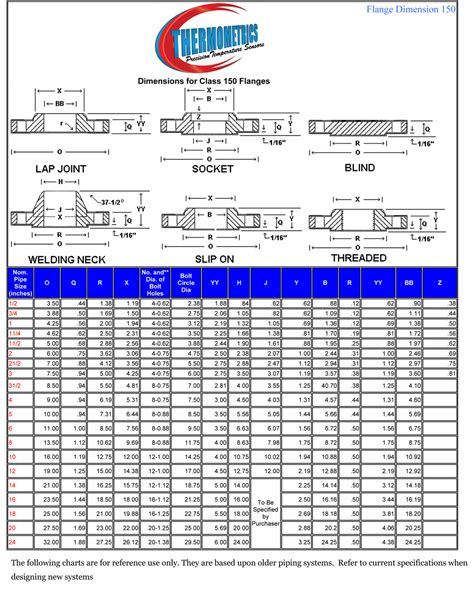

Flange Size Chart 1: ANSI Flange Size Chart

The ANSI flange size chart is one of the most commonly used charts in the industry. It provides a comprehensive guide to the different types and sizes of flanges available, including dimensions, pressure ratings, and material specifications.

Key Features of the ANSI Flange Size Chart

- Covers a wide range of flange sizes and types, including 150#, 300#, 600#, 900#, 1500#, and 2500#

- Provides detailed dimensions and pressure ratings for each flange size

- Includes material specifications for various types of flanges, including stainless steel, carbon steel, and alloy steel

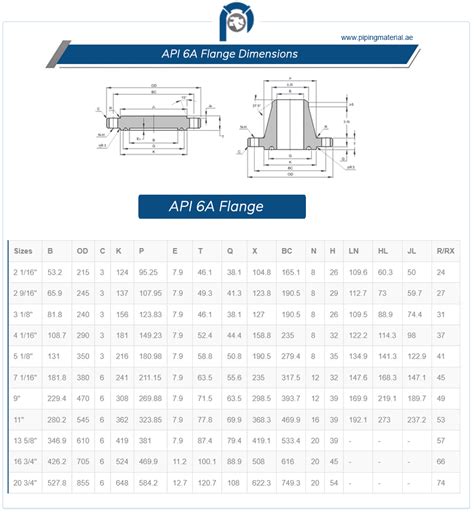

Flange Size Chart 2: API Flange Size Chart

The API flange size chart is designed for use in the oil and gas industry, where high-pressure and high-temperature applications are common. This chart provides a detailed guide to the different types and sizes of flanges available, including dimensions, pressure ratings, and material specifications.

Key Features of the API Flange Size Chart

- Covers a wide range of flange sizes and types, including 2,000, 3,000, 5,000, and 10,000 psi

- Provides detailed dimensions and pressure ratings for each flange size

- Includes material specifications for various types of flanges, including stainless steel, carbon steel, and alloy steel

Flange Size Chart 3: DIN Flange Size Chart

The DIN flange size chart is designed for use in European industries, where DIN standards are widely adopted. This chart provides a comprehensive guide to the different types and sizes of flanges available, including dimensions, pressure ratings, and material specifications.

Key Features of the DIN Flange Size Chart

- Covers a wide range of flange sizes and types, including PN6, PN10, PN16, PN25, and PN40

- Provides detailed dimensions and pressure ratings for each flange size

- Includes material specifications for various types of flanges, including stainless steel, carbon steel, and alloy steel

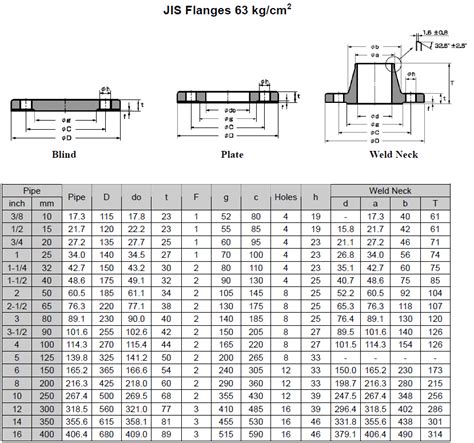

Flange Size Chart 4: JIS Flange Size Chart

The JIS flange size chart is designed for use in Japanese industries, where JIS standards are widely adopted. This chart provides a detailed guide to the different types and sizes of flanges available, including dimensions, pressure ratings, and material specifications.

Key Features of the JIS Flange Size Chart

- Covers a wide range of flange sizes and types, including 5K, 10K, 16K, 20K, and 30K

- Provides detailed dimensions and pressure ratings for each flange size

- Includes material specifications for various types of flanges, including stainless steel, carbon steel, and alloy steel

Flange Size Chart 5: BS Flange Size Chart

The BS flange size chart is designed for use in British industries, where BS standards are widely adopted. This chart provides a comprehensive guide to the different types and sizes of flanges available, including dimensions, pressure ratings, and material specifications.

Key Features of the BS Flange Size Chart

- Covers a wide range of flange sizes and types, including PN6, PN10, PN16, PN25, and PN40

- Provides detailed dimensions and pressure ratings for each flange size

- Includes material specifications for various types of flanges, including stainless steel, carbon steel, and alloy steel

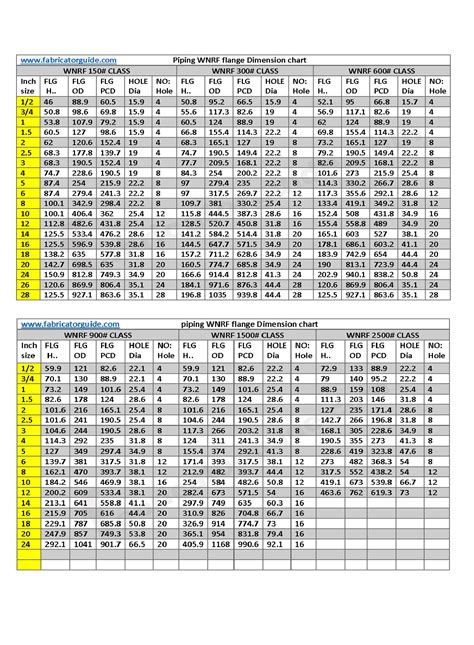

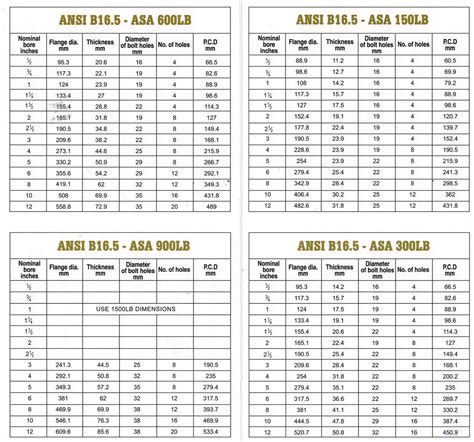

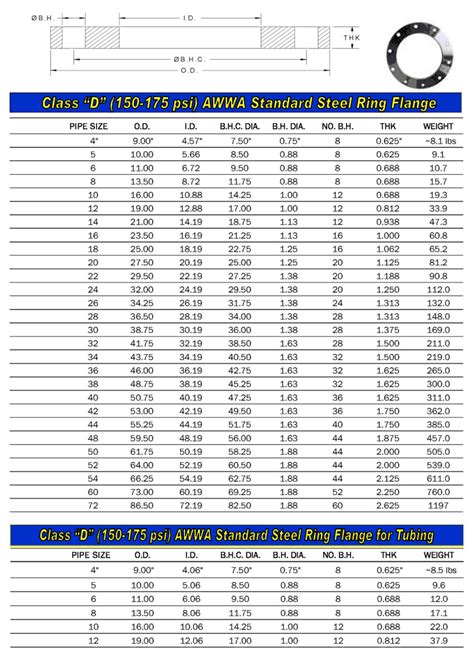

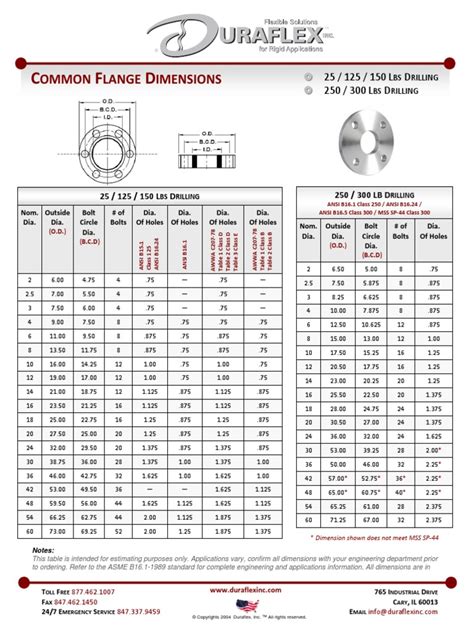

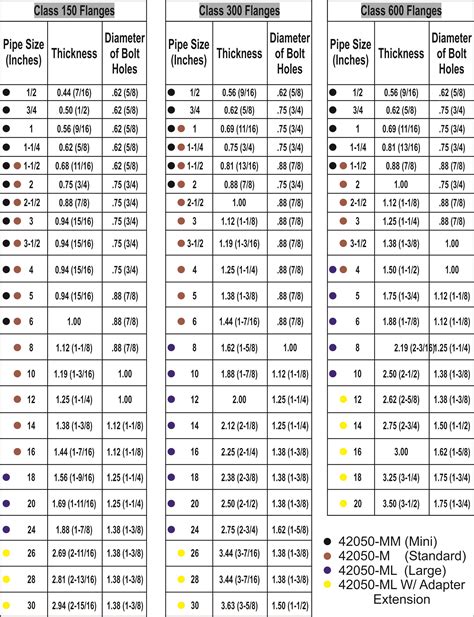

Flange Size Chart 6: ASME Flange Size Chart

The ASME flange size chart is designed for use in American industries, where ASME standards are widely adopted. This chart provides a detailed guide to the different types and sizes of flanges available, including dimensions, pressure ratings, and material specifications.

Key Features of the ASME Flange Size Chart

- Covers a wide range of flange sizes and types, including 150#, 300#, 600#, 900#, 1500#, and 2500#

- Provides detailed dimensions and pressure ratings for each flange size

- Includes material specifications for various types of flanges, including stainless steel, carbon steel, and alloy steel

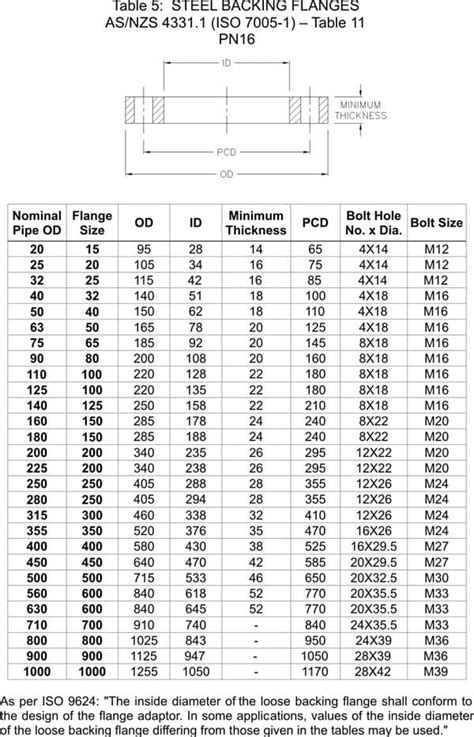

Flange Size Chart 7: ISO Flange Size Chart

The ISO flange size chart is designed for use in international industries, where ISO standards are widely adopted. This chart provides a comprehensive guide to the different types and sizes of flanges available, including dimensions, pressure ratings, and material specifications.

Key Features of the ISO Flange Size Chart

- Covers a wide range of flange sizes and types, including PN6, PN10, PN16, PN25, and PN40

- Provides detailed dimensions and pressure ratings for each flange size

- Includes material specifications for various types of flanges, including stainless steel, carbon steel, and alloy steel

Flange Size Chart Image Gallery

In conclusion, having a reliable flange size chart on hand can make all the difference in ensuring a smooth and efficient workflow. By printing out these 7 essential flange size charts, you'll be well-equipped to tackle any piping or fitting project that comes your way. Remember to always double-check your measurements and specifications to ensure accuracy and safety. Happy printing!

We'd love to hear from you! Have you found these flange size charts helpful? Do you have any other questions or topics you'd like us to cover? Let us know in the comments below.