Intro

Optimize your quality control processes with a free Cpk Excel template download. Calculate process capability and monitor performance using this essential tool. Learn how to improve manufacturing efficiency, reduce defects, and enhance overall product quality with a comprehensive guide to Cpk analysis and interpretation.

Process capability is a crucial aspect of quality control in manufacturing, and one of the most widely used metrics to measure it is Cpk (Process Capability Index). In this article, we will delve into the world of Cpk and explore how you can use an Excel template to simplify your quality control processes.

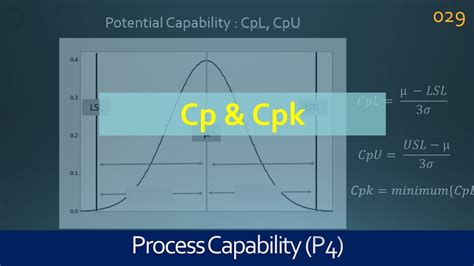

What is Cpk?

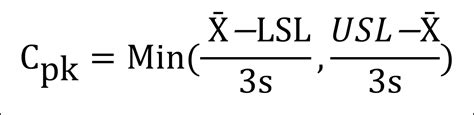

Cpk is a statistical measure that compares the variability of a process to its specifications. It is a widely accepted metric used to assess the ability of a process to produce output within specified limits. The Cpk value is calculated using the following formula:

Cpk = min (USL - μ, μ - LSL) / (3 * σ)

Where:

- USL = Upper Specification Limit

- LSL = Lower Specification Limit

- μ = Process Mean

- σ = Process Standard Deviation

A Cpk value of 1 or higher indicates that the process is capable of producing output within the specified limits. A value of less than 1 indicates that the process is not capable.

Why is Cpk important?

Cpk is an essential metric in quality control because it helps manufacturers:

- Evaluate the performance of their processes

- Identify areas for improvement

- Reduce waste and defects

- Improve customer satisfaction

- Comply with regulatory requirements

Using an Excel Template for Cpk Calculations

While Cpk calculations can be done manually, using an Excel template can simplify the process and reduce errors. An Excel template can help you:

- Organize your data

- Automate calculations

- Visualize results

- Identify trends and patterns

Free Cpk Excel Template Download

You can download a free Cpk Excel template from various websites or create your own using the following steps:

- Set up a new Excel worksheet

- Enter your data, including the upper and lower specification limits, process mean, and process standard deviation

- Use the Cpk formula to calculate the Cpk value

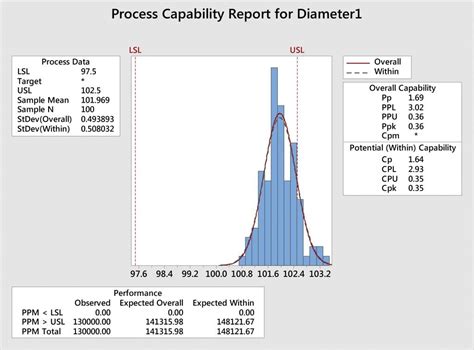

- Create a chart to visualize the results

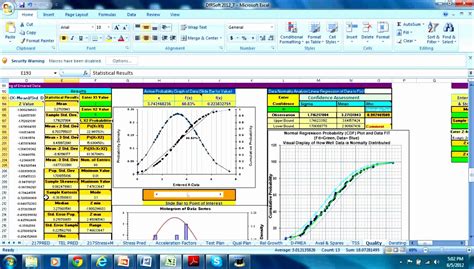

Here is an example of what the template might look like:

How to Use the Cpk Excel Template

Using the Cpk Excel template is straightforward. Here's a step-by-step guide:

- Enter your data into the template, including the upper and lower specification limits, process mean, and process standard deviation.

- The template will automatically calculate the Cpk value using the formula.

- Review the results to determine if your process is capable or not.

- Use the chart to visualize the results and identify trends and patterns.

Benefits of Using a Cpk Excel Template

Using a Cpk Excel template offers several benefits, including:

- Simplified calculations

- Reduced errors

- Improved accuracy

- Increased efficiency

- Enhanced visualization

Common Mistakes to Avoid When Using a Cpk Excel Template

While using a Cpk Excel template can simplify the calculation process, there are common mistakes to avoid:

- Incorrect data entry

- Inconsistent units

- Failure to update the template

- Ignoring trends and patterns

Tips for Improving Your Cpk Score

If your Cpk score is low, there are several tips to improve it:

- Reduce process variability

- Improve process centering

- Increase the specification limits

- Implement process control measures

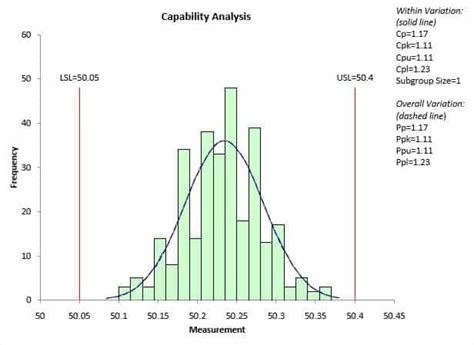

Gallery of Cpk-Related Images

Cpk Image Gallery

Conclusion

In conclusion, Cpk is a critical metric in quality control that helps manufacturers evaluate the performance of their processes. Using a Cpk Excel template can simplify the calculation process and improve accuracy. By following the tips and avoiding common mistakes, you can improve your Cpk score and achieve higher quality standards.

We hope this article has been informative and helpful. If you have any questions or need further assistance, please don't hesitate to comment below.