Intro

Discover the remarkable story of Building The Channel Tunnel, a 31-mile undersea marvel of engineering that connects England and France. Learn about the groundbreaking construction techniques, innovative technologies, and incredible feats of engineering that made this monumental project a reality, showcasing human ingenuity and perseverance.

The Channel Tunnel, also known as the Eurotunnel, is a remarkable feat of engineering that has revolutionized travel between England and France. Connecting the two countries under the English Channel, the tunnel has been in operation since 1994 and has had a significant impact on the economies and cultures of both nations. The construction of the Channel Tunnel was a monumental task that required innovative solutions, cutting-edge technology, and unparalleled collaboration.

The idea of building a tunnel under the English Channel dates back to the 19th century, but it wasn't until the 1980s that the project gained momentum. The British and French governments signed a treaty in 1986, paving the way for the construction of the Channel Tunnel. The project was undertaken by a consortium of British and French companies, led by the Eurotunnel Group.

Design and Construction

The Channel Tunnel is approximately 50 kilometers (31 miles) long, with 38 kilometers (24 miles) of undersea tunnel. The tunnel has two running tunnels, one for each direction, and a smaller service tunnel in between. The tunnels were constructed using a combination of drilling and blasting, and a tunnel boring machine (TBM). The TBM was used to excavate the undersea section of the tunnel, while the drilling and blasting method was employed for the onshore sections.

The tunnel's design was influenced by the geology of the English Channel. The undersea section of the tunnel was constructed through a layer of chalk marl, a type of rock that is relatively easy to excavate. However, the tunnel also had to navigate through a layer of harder rock, known as the "Gault Clay," which required specialized drilling equipment.

Challenges and Innovations

The construction of the Channel Tunnel was not without its challenges. One of the most significant hurdles was the need to excavate through the Gault Clay, which was much harder than anticipated. To overcome this, the engineers developed a new type of drilling equipment that used a combination of water and abrasive particles to break through the rock.

Another significant challenge was the need to ensure the tunnel's stability and safety. The tunnel had to be designed to withstand the pressure of the water above, as well as the potential for earthquakes and other seismic activity. To address this, the engineers developed a sophisticated system of support structures and linings to maintain the tunnel's stability.

Operational Features

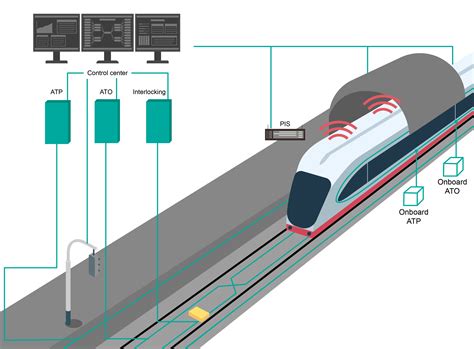

The Channel Tunnel has several operational features that make it one of the most advanced transportation systems in the world. The tunnel has two running tunnels, each with a diameter of 7.6 meters (25 feet), and a smaller service tunnel in between. The running tunnels are equipped with advanced signaling and control systems, allowing for safe and efficient operation.

The tunnel also has advanced ventilation and fire suppression systems, which are designed to maintain a safe environment for passengers and crew. The tunnel is operated by a team of highly trained personnel, who monitor the tunnel's systems and respond to any incidents or emergencies.

Economic and Cultural Impact

The Channel Tunnel has had a significant impact on the economies and cultures of both England and France. The tunnel has increased trade and tourism between the two countries, with millions of passengers and tons of freight passing through the tunnel each year.

The tunnel has also facilitated the exchange of ideas and cultures between the two countries, with many students, artists, and professionals traveling through the tunnel for educational and cultural purposes.

Environmental Considerations

The construction of the Channel Tunnel was subject to strict environmental regulations and guidelines. The tunnel's designers and engineers took care to minimize the tunnel's impact on the environment, with measures such as reducing noise pollution and protecting marine life.

The tunnel's operators also take steps to reduce the tunnel's carbon footprint, with measures such as using energy-efficient lighting and reducing waste.

Future Developments

The Channel Tunnel has undergone several upgrades and improvements since its opening in 1994. The tunnel's operators have invested in new technology and infrastructure, including advanced signaling and control systems, to improve safety and efficiency.

The tunnel's operators are also exploring new ways to reduce the tunnel's environmental impact, including the use of renewable energy sources and sustainable materials.

Channel Tunnel Image Gallery

As we look to the future, it's clear that the Channel Tunnel will continue to play a vital role in connecting England and France. With ongoing upgrades and improvements, the tunnel will remain a marvel of engineering and a testament to human ingenuity.

We invite you to share your thoughts on the Channel Tunnel and its impact on the world. Have you traveled through the tunnel? What are your thoughts on its design and construction? Let us know in the comments below!