Intro

Unlock the roles and responsibilities of an Industrial Engineer. Discover the top 8 duties of an Industrial Engineer job description, including process optimization, quality control, and supply chain management. Learn about the key skills and qualifications required for success in this field, and explore the various industries where Industrial Engineers play a crucial role.

As an industrial engineer, your primary goal is to optimize the efficiency and productivity of industrial processes and systems. This role requires a unique blend of technical expertise, business acumen, and problem-solving skills. If you're considering a career as an industrial engineer or simply want to learn more about this fascinating field, here's an in-depth look at the top 8 duties of an industrial engineer job description.

Understanding the Role of an Industrial Engineer

Industrial engineers play a critical role in designing, implementing, and improving integrated systems that include people, materials, equipment, and energy. They aim to minimize waste, reduce costs, and maximize productivity in various industries, including manufacturing, healthcare, and logistics. To achieve this, industrial engineers must be proficient in a wide range of skills, from data analysis and process optimization to project management and communication.

Key Responsibilities of an Industrial Engineer

Here are the top 8 duties of an industrial engineer job description:

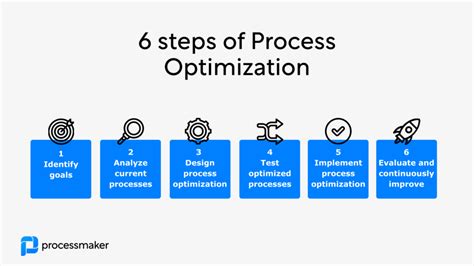

1. Process Optimization

Industrial engineers are responsible for analyzing and optimizing business processes to improve efficiency, reduce waste, and increase productivity. This involves identifying areas for improvement, designing and implementing new processes, and monitoring their effectiveness.

Key Activities:

- Analyze data to identify bottlenecks and areas for improvement

- Design and implement new processes and systems

- Collaborate with stakeholders to ensure successful implementation

- Monitor and evaluate process performance

2. Project Management

Industrial engineers often manage projects related to process improvement, new product development, or equipment installation. This involves planning, coordinating, and controlling resources to ensure projects are completed on time, within budget, and to the required quality standards.

Key Activities:

- Plan and coordinate project resources and timelines

- Manage project budgets and ensure cost-effectiveness

- Collaborate with stakeholders to ensure successful project outcomes

- Monitor and report on project progress

3. Data Analysis

Industrial engineers use data analysis to identify trends, patterns, and areas for improvement in industrial processes. This involves collecting and analyzing data, interpreting results, and making recommendations for improvement.

Key Activities:

- Collect and analyze data from various sources

- Identify trends, patterns, and areas for improvement

- Interpret results and make recommendations for improvement

- Develop and implement data-driven solutions

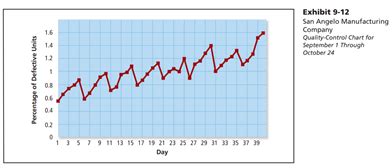

4. Quality Control

Industrial engineers are responsible for ensuring that products meet quality and safety standards. This involves designing and implementing quality control processes, monitoring product quality, and identifying areas for improvement.

Key Activities:

- Design and implement quality control processes

- Monitor product quality and identify areas for improvement

- Collaborate with stakeholders to ensure successful implementation

- Develop and implement quality improvement initiatives

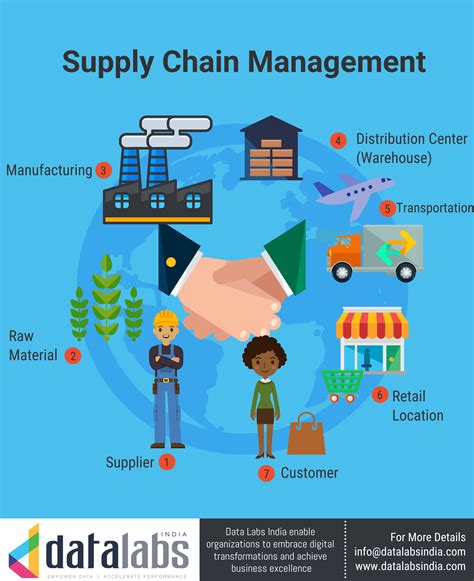

5. Supply Chain Management

Industrial engineers often work on supply chain management projects, aiming to optimize the flow of goods, services, and information from raw materials to end customers. This involves analyzing supply chain processes, identifying areas for improvement, and implementing changes to increase efficiency and reduce costs.

Key Activities:

- Analyze supply chain processes and identify areas for improvement

- Develop and implement supply chain improvement initiatives

- Collaborate with stakeholders to ensure successful implementation

- Monitor and evaluate supply chain performance

6. Equipment Installation and Maintenance

Industrial engineers are responsible for ensuring that equipment is installed, maintained, and repaired correctly. This involves designing and implementing equipment installation and maintenance processes, monitoring equipment performance, and identifying areas for improvement.

Key Activities:

- Design and implement equipment installation and maintenance processes

- Monitor equipment performance and identify areas for improvement

- Collaborate with stakeholders to ensure successful implementation

- Develop and implement equipment improvement initiatives

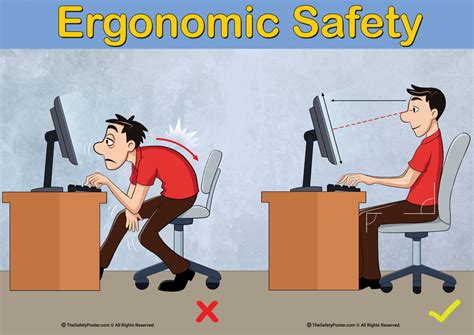

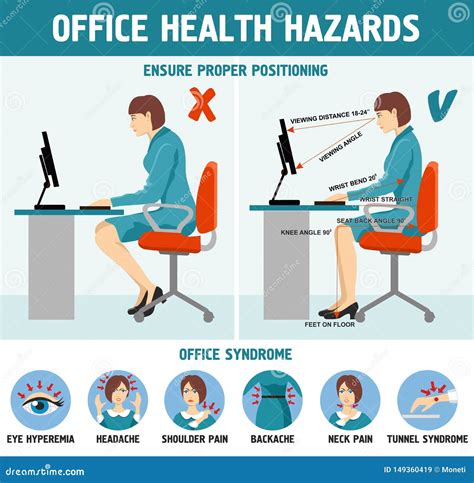

7. Safety and Ergonomics

Industrial engineers must ensure that workplaces are safe and ergonomic for employees. This involves designing and implementing safety and ergonomic processes, monitoring workplace safety, and identifying areas for improvement.

Key Activities:

- Design and implement safety and ergonomic processes

- Monitor workplace safety and identify areas for improvement

- Collaborate with stakeholders to ensure successful implementation

- Develop and implement safety and ergonomic improvement initiatives

8. Communication and Collaboration

Industrial engineers must communicate effectively with stakeholders, including employees, management, and customers. This involves presenting data and recommendations, negotiating with stakeholders, and building strong relationships.

Key Activities:

- Communicate effectively with stakeholders

- Present data and recommendations

- Negotiate with stakeholders

- Build strong relationships with stakeholders

Industrial Engineer Job Description Image Gallery

We hope this article has provided you with a comprehensive understanding of the top 8 duties of an industrial engineer job description. Whether you're a seasoned professional or just starting your career, this information can help you navigate the complex world of industrial engineering and achieve success in your role.