Intro

Optimize your jet nozzle performance with expert website design and manufacturing solutions. Discover cutting-edge technologies and innovative designs that enhance fluid dynamics, increase efficiency, and reduce costs. From custom engineering to 3D printing, explore the latest advancements in jet nozzle manufacturing and website design for superior results.

The importance of effective jet nozzle design and manufacturing cannot be overstated, particularly in industries where precise fluid flow control is crucial. From aerospace and defense to chemical processing and oil refining, the performance of jet nozzles plays a significant role in determining the efficiency, safety, and overall success of various operations. In this article, we will delve into the world of jet nozzle design and manufacturing, exploring the key considerations, benefits, and solutions that can help organizations optimize their processes and achieve their goals.

Understanding Jet Nozzles

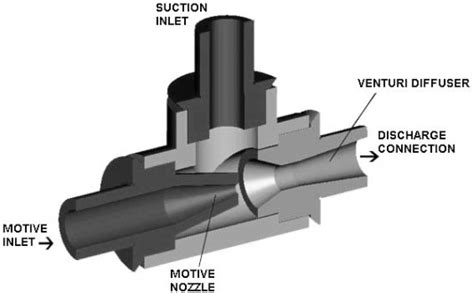

A jet nozzle is a device designed to control the flow of fluids, such as liquids or gases, by accelerating or decelerating them through a narrow opening or orifice. The nozzle's shape, size, and material properties all contribute to its performance, making it a critical component in various applications. In aerospace, for example, jet nozzles are used in rocket engines to propel vehicles into space, while in chemical processing, they are used to mix and blend substances.

Key Considerations in Jet Nozzle Design

When designing a jet nozzle, several factors must be taken into account to ensure optimal performance. These include:

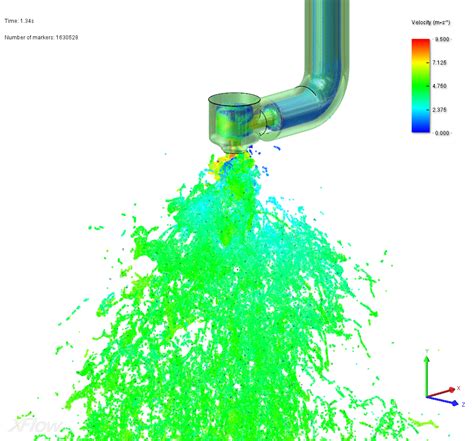

- Fluid properties: The type of fluid being used, its viscosity, density, and other characteristics all impact nozzle design.

- Flow rate: The desired flow rate of the fluid will influence the nozzle's size and shape.

- Pressure: The operating pressure of the system will affect the nozzle's material selection and design.

- Temperature: The temperature of the fluid and the surrounding environment will impact the nozzle's material selection and design.

Journey of Jet Nozzle Manufacturing

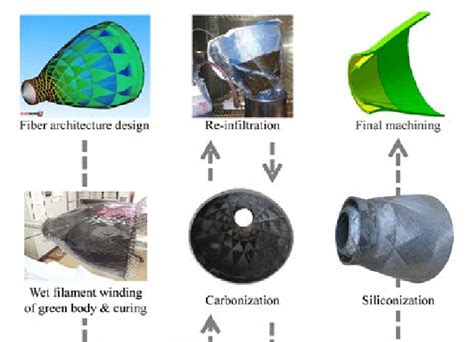

The manufacturing process for jet nozzles typically involves several stages, including:

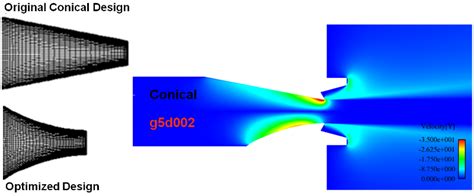

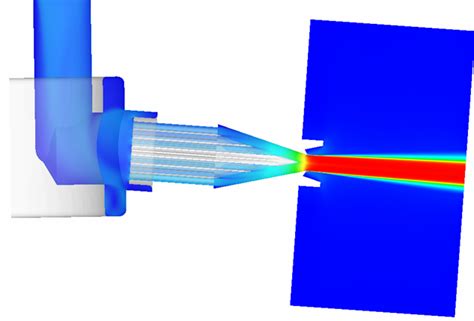

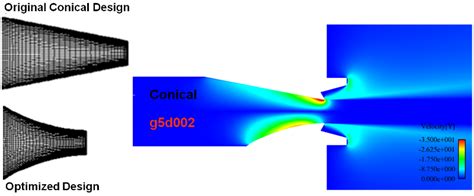

- Design: Using computer-aided design (CAD) software and computational fluid dynamics (CFD) analysis, the nozzle's design is created and optimized.

- Material selection: The choice of material will depend on the operating conditions, such as temperature, pressure, and fluid properties.

- Machining: The nozzle is machined from the selected material using techniques such as turning, milling, or drilling.

- Quality control: The finished nozzle is inspected for quality and performance.

Benefits of Custom Jet Nozzle Design and Manufacturing

Custom jet nozzle design and manufacturing offer several benefits, including:

- Improved performance: A custom-designed nozzle can optimize fluid flow, leading to improved efficiency and reduced energy consumption.

- Increased safety: A well-designed nozzle can reduce the risk of accidents and ensure a safer working environment.

- Cost savings: Custom nozzles can be designed to minimize material waste and reduce production costs.

Website Design Solutions for Jet Nozzle Manufacturers

In today's digital age, having a professional website is crucial for businesses, including jet nozzle manufacturers. A well-designed website can help manufacturers showcase their products, services, and expertise, while also providing a platform for customers to learn about and engage with the company.

- Responsive design: A responsive website design ensures that the site is accessible and user-friendly across various devices and browsers.

- Content management: A content management system (CMS) allows manufacturers to easily update and manage their website's content.

- E-commerce integration: An e-commerce platform enables manufacturers to sell their products online, expanding their customer reach.

Javascript Solutions for Jet Nozzle Website Design

Javascript can be used to enhance the functionality and user experience of a jet nozzle manufacturer's website. Some examples include:

- Interactive 3D models: Javascript can be used to create interactive 3D models of jet nozzles, allowing customers to explore and visualize the products.

- Calculators and tools: Javascript can be used to develop calculators and tools that help customers design and optimize their jet nozzles.

- Animations and simulations: Javascript can be used to create animations and simulations that demonstrate the performance and benefits of jet nozzles.

FAQs

- What is a jet nozzle? A jet nozzle is a device designed to control the flow of fluids, such as liquids or gases, by accelerating or decelerating them through a narrow opening or orifice.

- What are the benefits of custom jet nozzle design and manufacturing? Custom jet nozzle design and manufacturing offer several benefits, including improved performance, increased safety, and cost savings.

- How can a website design solution help jet nozzle manufacturers? A website design solution can help jet nozzle manufacturers showcase their products, services, and expertise, while also providing a platform for customers to learn about and engage with the company.

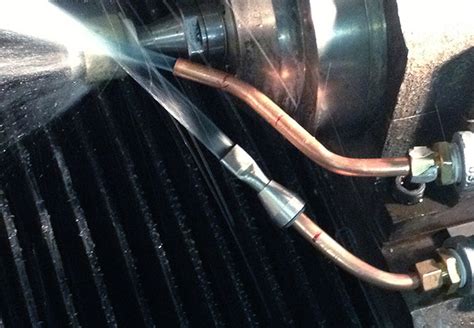

Jet Nozzle Image Gallery

We hope this article has provided you with a comprehensive understanding of jet nozzle design and manufacturing solutions. If you have any further questions or would like to learn more about our services, please don't hesitate to contact us.