Intro

Lightsabers, the iconic symbol of power and agility in the Star Wars universe, have captured the imagination of fans worldwide. For those who want to bring a piece of this galaxy far, far away into their own world, printing a lightsaber handle is a fantastic starting point. Whether you're a seasoned DIY enthusiast or a beginner in the realm of 3D printing, this article will guide you through five ways to print a lightsaber handle that will make you feel like a Jedi Master.

What You Need to Know Before Printing

Before diving into the various methods of printing a lightsaber handle, it's essential to understand the basics of 3D printing and the specific requirements for creating a lightsaber handle. You'll need:

- A 3D printer (FDM or resin)

- 3D modeling software (e.g., Blender, Fusion 360)

- A lightsaber handle design (available online or created from scratch)

- Filament or resin (depending on your printer type)

Understanding Lightsaber Handle Designs

Lightsaber handle designs vary greatly, from simple to intricate, and can be inspired by various characters from the Star Wars universe. When choosing a design, consider the complexity, size, and material requirements. You can find numerous designs online or create your own using 3D modeling software.

Method 1: FDM Printing with PLA Filament

FDM (Fused Deposition Modeling) printing is the most common 3D printing technique, using melted plastic filament to create objects layer by layer.

- Advantages: Affordable, easy to use, and fast printing speeds

- Disadvantages: Limited detail resolution, potential warping or layer shifting

To print a lightsaber handle using FDM, follow these steps:

- Prepare your 3D model and slice it into layers using software like Cura or Slic3r.

- Load PLA filament into your FDM printer and set the desired temperature and speed.

- Start the print job and monitor the process for any issues.

Method 2: Resin Printing with SLA Technology

SLA (Stereolithography) printing uses a laser to solidify liquid resin, creating highly detailed objects with smooth surfaces.

- Advantages: High detail resolution, smooth surfaces, and accurate dimensions

- Disadvantages: Expensive, slow printing speeds, and post-processing requirements

To print a lightsaber handle using SLA, follow these steps:

- Prepare your 3D model and generate support structures using software like PreForm.

- Load resin into your SLA printer and set the desired exposure settings.

- Start the print job and monitor the process for any issues.

Method 3: Hybrid Printing with FDM and Resin

Hybrid printing combines the strengths of FDM and SLA technologies, allowing for detailed prints with fast printing speeds.

- Advantages: Fast printing speeds, high detail resolution, and affordable

- Disadvantages: Limited availability of hybrid printers, potential complexity

To print a lightsaber handle using hybrid printing, follow these steps:

- Prepare your 3D model and slice it into layers using software like Cura or Slic3r.

- Load PLA filament into your FDM printer and set the desired temperature and speed.

- Switch to resin printing and load the resin into your hybrid printer.

- Start the print job and monitor the process for any issues.

Method 4: Casting with 3D Printed Molds

Casting involves creating a 3D printed mold and filling it with a material, such as resin or metal, to create the final object.

- Advantages: High detail resolution, smooth surfaces, and durable materials

- Disadvantages: Time-consuming, requires additional materials and equipment

To print a lightsaber handle using casting, follow these steps:

- Prepare your 3D model and create a mold using software like Blender or Fusion 360.

- Print the mold using FDM or SLA technology.

- Fill the mold with the desired material and allow it to set.

- Remove the object from the mold and post-process as necessary.

Method 5: CNC Machining with 3D Printed Templates

CNC machining involves using a 3D printed template to guide a CNC machine in creating the final object.

- Advantages: High accuracy, durable materials, and fast production times

- Disadvantages: Requires access to CNC machinery, limited availability

To print a lightsaber handle using CNC machining, follow these steps:

- Prepare your 3D model and create a template using software like Blender or Fusion 360.

- Print the template using FDM or SLA technology.

- Set up the CNC machine with the template and desired material.

- Start the machining process and monitor the results.

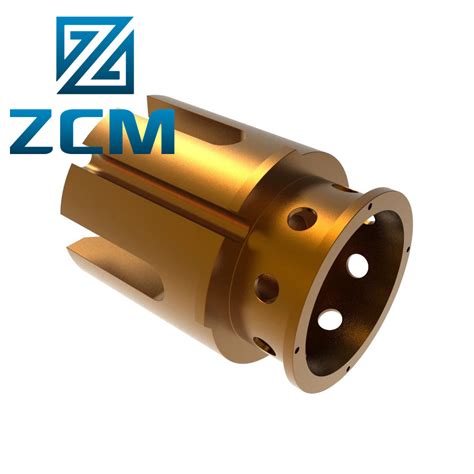

Lightsaber Handle Image Gallery

We hope this comprehensive guide has inspired you to create your own lightsaber handle using one of the five methods outlined above. Whether you're a seasoned maker or a beginner, remember to always follow safety guidelines and best practices when working with 3D printing and other technologies. May the Force be with you!