Intro

Discover expert advice on maintaining low observable aircraft structures with our 5 essential tips. Learn how to preserve stealth technology, reduce radar cross-sections, and ensure combat readiness. From inspection techniques to material preservation, our guide covers key considerations for aircraft maintenance personnel to minimize visibility and maximize effectiveness.

As the world of aviation continues to evolve, the need for advanced aircraft technologies has become increasingly important. One such technology is Low Observable (LO) aircraft, also known as stealth aircraft. These aircraft are designed to evade detection by radar and other sensors, making them ideal for military and surveillance operations. However, maintaining the structural integrity of LO aircraft requires specialized techniques and materials. In this article, we will discuss five tips for low observable aircraft structural maintenance.

Understanding the Importance of Low Observable Technology

LO technology is designed to reduce the radar cross-section (RCS) of an aircraft, making it difficult to detect. This is achieved through the use of radar-absorbent materials (RAMs) and specially designed shapes. However, these materials and shapes can be damaged or compromised during maintenance, which can affect the aircraft's LO capabilities.

Tip 1: Use Specialized Cleaning Agents

When cleaning LO aircraft, it's essential to use specialized cleaning agents that won't damage the RAMs or compromise the aircraft's LO capabilities. Traditional cleaning agents can strip away the radar-absorbent properties of the materials, reducing the aircraft's effectiveness. Use cleaning agents specifically designed for LO aircraft, and always follow the manufacturer's instructions.

Tip 2: Avoid Using Abrasive Materials

Abrasive materials can damage the RAMs and compromise the aircraft's LO capabilities. When performing maintenance tasks, avoid using abrasive materials such as sandpaper or steel wool. Instead, use soft, non-abrasive materials that won't damage the surfaces.

Tip 3: Use Radar-Absorbent Materials for Repairs

When repairing LO aircraft, it's essential to use radar-absorbent materials that match the original materials. This ensures that the aircraft's LO capabilities are maintained. Use materials that are specifically designed for LO aircraft, and always follow the manufacturer's instructions.

Tip 4: Follow Manufacturer's Instructions

When performing maintenance tasks on LO aircraft, it's essential to follow the manufacturer's instructions. This ensures that the aircraft's LO capabilities are maintained and that the materials are not damaged. Always refer to the manufacturer's documentation and follow the recommended procedures.

Tip 5: Use Non-Destructive Testing Methods

Non-destructive testing (NDT) methods are essential for LO aircraft maintenance. These methods allow technicians to inspect the aircraft's structures without damaging the materials. Use NDT methods such as ultrasonic testing or radiography to inspect the aircraft's structures and detect any potential issues.

Common Challenges in LO Aircraft Maintenance

LO aircraft maintenance can be challenging due to the specialized materials and techniques required. Some common challenges include:

- Damage to radar-absorbent materials during maintenance

- Compromising the aircraft's LO capabilities during repairs

- Difficulty in inspecting the aircraft's structures without damaging the materials

Best Practices for LO Aircraft Maintenance

To ensure the structural integrity of LO aircraft, follow these best practices:

- Use specialized cleaning agents and avoid using abrasive materials

- Use radar-absorbent materials for repairs and follow the manufacturer's instructions

- Use non-destructive testing methods to inspect the aircraft's structures

- Always refer to the manufacturer's documentation and follow the recommended procedures

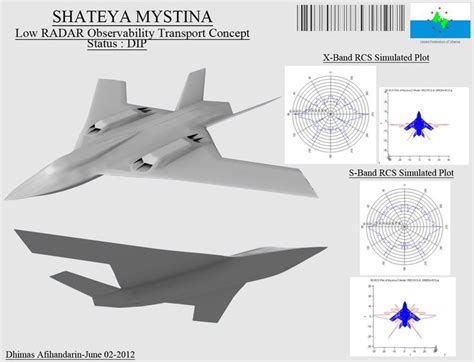

Low Observable Aircraft Image Gallery

By following these tips and best practices, technicians can ensure the structural integrity of LO aircraft and maintain their effectiveness.