Intro

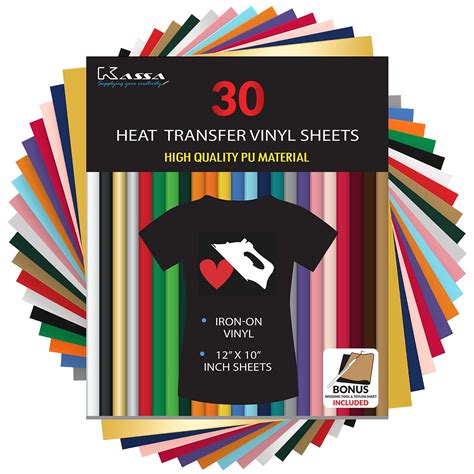

Learn how to make market printable heat transfer sheets easily at home with our step-by-step guide. Discover the best materials, printers, and techniques for creating custom heat transfers for t-shirts, hoodies, and more. DIY heat transfer vinyl sheets with ease and start your own home-based printing business.

Are you tired of paying high prices for heat transfer sheets at craft stores? Do you want to create custom designs and prints for your favorite t-shirts, hoodies, or tote bags? Making market printable heat transfer sheets at home is easier than you think. With a few simple materials and some basic knowledge, you can create your own heat transfer sheets and start printing your designs in no time.

Heat transfer sheets, also known as heat transfer paper or iron-on transfers, are a popular way to add custom designs, logos, and text to fabrics. They are widely used in the craft and DIY communities, as well as in small businesses and entrepreneurial ventures. By making your own heat transfer sheets at home, you can save money, increase your creativity, and produce high-quality prints that rival those of commercial products.

What You Need to Get Started

To make market printable heat transfer sheets at home, you'll need a few basic materials. These include:

- A printer: You can use either an inkjet or laser printer, but inkjet printers are generally recommended for heat transfer printing.

- Heat transfer paper: You can purchase heat transfer paper online or at craft stores. Make sure to choose a paper that is specifically designed for your printer type (inkjet or laser).

- A cutting tool: You'll need a cutting tool, such as scissors or a craft knife, to cut your heat transfer sheets to size.

- A heat press: A heat press is a specialized tool that applies heat and pressure to your heat transfer sheets. You can purchase a heat press online or at craft stores.

- Designs and software: You'll need a computer and design software, such as Adobe Photoshop or Illustrator, to create your custom designs and prints.

Step-by-Step Instructions

Making market printable heat transfer sheets at home is a relatively simple process. Here's a step-by-step guide to get you started:

- Prepare your design: Use your computer and design software to create your custom design or print. Make sure to mirror your design, as it will be reversed when printed on the heat transfer sheet.

- Print your design: Print your design onto the heat transfer paper using your inkjet or laser printer. Follow the manufacturer's instructions for printing heat transfer paper.

- Cut your heat transfer sheet: Use your cutting tool to cut your heat transfer sheet to size. Make sure to cut along the edges of the paper, leaving a small margin around the design.

- Prepare your fabric: Choose the fabric you want to print on, such as a t-shirt, hoodie, or tote bag. Make sure the fabric is clean and dry.

- Apply heat and pressure: Place the heat transfer sheet onto the fabric, making sure to align it properly. Apply heat and pressure using your heat press, following the manufacturer's instructions.

- Peel off the paper: After applying heat and pressure, peel off the paper backing to reveal your custom design or print.

Tips and Variations

Here are some tips and variations to help you make the most of your heat transfer sheets:

- Use different colors and designs: Experiment with different colors and designs to create unique and personalized prints.

- Add textures and effects: Use textures and effects, such as glitter or holographic foil, to add an extra dimension to your prints.

- Print on different fabrics: Experiment with printing on different fabrics, such as cotton, polyester, or blends.

- Use a heat press with a temperature control: A heat press with a temperature control allows you to adjust the temperature to suit different fabrics and designs.

Benefits of Making Your Own Heat Transfer Sheets

Making your own heat transfer sheets at home has several benefits. These include:

- Cost savings: Making your own heat transfer sheets can save you money compared to buying commercial products.

- Increased creativity: With the ability to create custom designs and prints, you can express your creativity and bring your ideas to life.

- High-quality prints: With the right materials and techniques, you can produce high-quality prints that rival those of commercial products.

- Convenience: Making your own heat transfer sheets at home is convenient and allows you to print on demand.

Common Mistakes to Avoid

Here are some common mistakes to avoid when making heat transfer sheets:

- Incorrect temperature: Using the wrong temperature can damage your heat transfer sheets or result in poor-quality prints.

- Insufficient pressure: Applying insufficient pressure can result in poor-quality prints or the heat transfer sheet not adhering properly to the fabric.

- Incorrect paper size: Using the wrong paper size can result in wasted paper or poor-quality prints.

- Poor design preparation: Failing to mirror your design or prepare it properly can result in poor-quality prints.

Gallery of Heat Transfer Sheet Making

Heat Transfer Sheet Making Gallery

We hope this article has inspired you to start making your own heat transfer sheets at home. With the right materials and techniques, you can create high-quality prints that rival those of commercial products. Remember to follow the step-by-step instructions, tips, and variations to ensure the best results. Happy crafting!

What do you think about making your own heat transfer sheets at home? Share your thoughts, ideas, and experiences in the comments below.