Effective maintenance is crucial for any organization to ensure that its equipment, assets, and facilities are in good working condition. A well-planned maintenance schedule can help prevent equipment failures, reduce downtime, and increase overall productivity. One of the most efficient ways to manage maintenance is by using Microsoft Excel. In this article, we will discuss the importance of maintenance scheduling and provide five essential monthly maintenance schedules that you can easily create and manage in Excel.

Benefits of Maintenance Scheduling in Excel

Maintenance scheduling in Excel offers numerous benefits, including:

- Improved organization and planning

- Enhanced visibility and tracking of maintenance activities

- Reduced errors and omissions

- Increased efficiency and productivity

- Better decision-making through data analysis

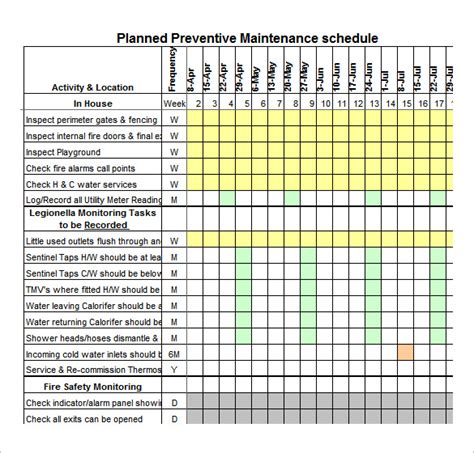

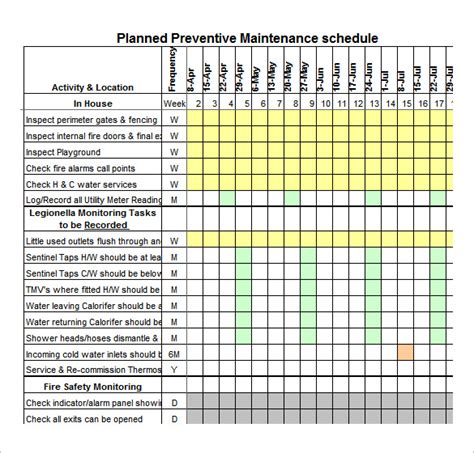

Monthly Maintenance Schedule 1: Preventive Maintenance

Preventive maintenance is a proactive approach to maintenance that involves regular checks and maintenance activities to prevent equipment failures. A monthly preventive maintenance schedule in Excel can help you stay on top of maintenance tasks and reduce downtime.

Here is an example of a monthly preventive maintenance schedule in Excel:

| Equipment | Maintenance Task | Frequency | Due Date |

|---|---|---|---|

| Air Compressor | Oil change | Monthly | 15th of every month |

| Pumps | Inspection | Monthly | 20th of every month |

| Motors | Lubrication | Monthly | 25th of every month |

Creating a Preventive Maintenance Schedule in Excel

To create a preventive maintenance schedule in Excel, follow these steps:

- Create a table with the following columns: Equipment, Maintenance Task, Frequency, and Due Date.

- Enter the equipment, maintenance task, frequency, and due date for each maintenance activity.

- Use the Autofill feature to fill in the due dates for each month.

- Use conditional formatting to highlight overdue maintenance tasks.

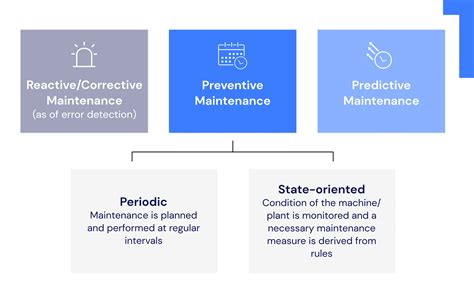

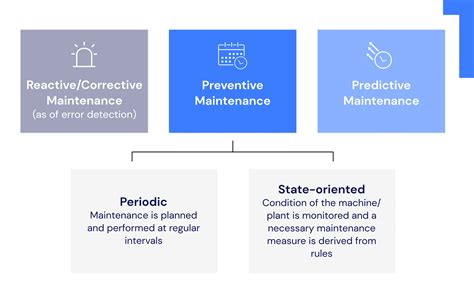

Monthly Maintenance Schedule 2: Corrective Maintenance

Corrective maintenance involves repairing or replacing equipment that has failed or is not functioning properly. A monthly corrective maintenance schedule in Excel can help you track and manage corrective maintenance activities.

Here is an example of a monthly corrective maintenance schedule in Excel:

| Equipment | Failure Date | Maintenance Task | Status |

|---|---|---|---|

| Pump 1 | 10th of the month | Repair | In progress |

| Motor 2 | 15th of the month | Replace | Completed |

| Air Compressor | 20th of the month | Repair | Pending |

Creating a Corrective Maintenance Schedule in Excel

To create a corrective maintenance schedule in Excel, follow these steps:

- Create a table with the following columns: Equipment, Failure Date, Maintenance Task, and Status.

- Enter the equipment, failure date, maintenance task, and status for each corrective maintenance activity.

- Use the Autofill feature to fill in the dates for each month.

- Use conditional formatting to highlight completed and pending maintenance tasks.

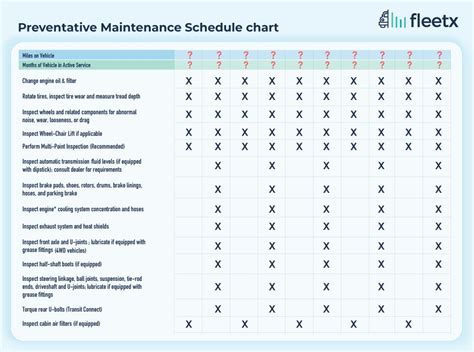

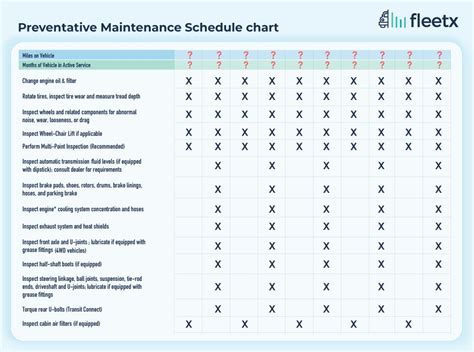

Monthly Maintenance Schedule 3: Predictive Maintenance

Predictive maintenance involves using data and analytics to predict when equipment is likely to fail. A monthly predictive maintenance schedule in Excel can help you identify potential equipment failures and take proactive measures to prevent them.

Here is an example of a monthly predictive maintenance schedule in Excel:

| Equipment | Sensor Reading | Threshold | Predicted Failure Date |

|---|---|---|---|

| Pump 1 | 80% | 90% | 15th of the month |

| Motor 2 | 70% | 80% | 20th of the month |

| Air Compressor | 60% | 70% | 25th of the month |

Creating a Predictive Maintenance Schedule in Excel

To create a predictive maintenance schedule in Excel, follow these steps:

- Create a table with the following columns: Equipment, Sensor Reading, Threshold, and Predicted Failure Date.

- Enter the equipment, sensor reading, threshold, and predicted failure date for each predictive maintenance activity.

- Use the Autofill feature to fill in the dates for each month.

- Use conditional formatting to highlight equipment that is likely to fail.

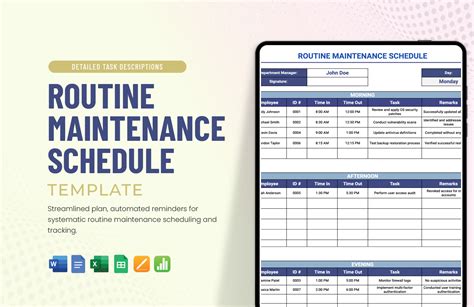

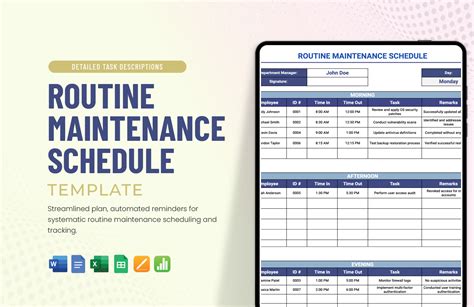

Monthly Maintenance Schedule 4: Routine Maintenance

Routine maintenance involves performing regular maintenance tasks to keep equipment in good working condition. A monthly routine maintenance schedule in Excel can help you stay on top of routine maintenance activities.

Here is an example of a monthly routine maintenance schedule in Excel:

| Equipment | Maintenance Task | Frequency | Due Date |

|---|---|---|---|

| Air Compressor | Filter cleaning | Weekly | Every Monday |

| Pumps | Inspection | Bi-weekly | Every other Wednesday |

| Motors | Lubrication | Monthly | 15th of every month |

Creating a Routine Maintenance Schedule in Excel

To create a routine maintenance schedule in Excel, follow these steps:

- Create a table with the following columns: Equipment, Maintenance Task, Frequency, and Due Date.

- Enter the equipment, maintenance task, frequency, and due date for each routine maintenance activity.

- Use the Autofill feature to fill in the due dates for each month.

- Use conditional formatting to highlight overdue maintenance tasks.

Monthly Maintenance Schedule 5: Emergency Maintenance

Emergency maintenance involves performing maintenance tasks in response to an unexpected equipment failure. A monthly emergency maintenance schedule in Excel can help you track and manage emergency maintenance activities.

Here is an example of a monthly emergency maintenance schedule in Excel:

| Equipment | Failure Date | Maintenance Task | Status |

|---|---|---|---|

| Pump 1 | 10th of the month | Repair | Completed |

| Motor 2 | 15th of the month | Replace | In progress |

| Air Compressor | 20th of the month | Repair | Pending |

Creating an Emergency Maintenance Schedule in Excel

To create an emergency maintenance schedule in Excel, follow these steps:

- Create a table with the following columns: Equipment, Failure Date, Maintenance Task, and Status.

- Enter the equipment, failure date, maintenance task, and status for each emergency maintenance activity.

- Use the Autofill feature to fill in the dates for each month.

- Use conditional formatting to highlight completed and pending maintenance tasks.

Maintenance Scheduling in Excel Image Gallery

We hope this article has provided you with a comprehensive guide to creating essential monthly maintenance schedules in Excel. By using these schedules, you can improve your maintenance operations and reduce downtime. Remember to regularly review and update your schedules to ensure that they remain effective and relevant. If you have any questions or need further assistance, please don't hesitate to comment below.