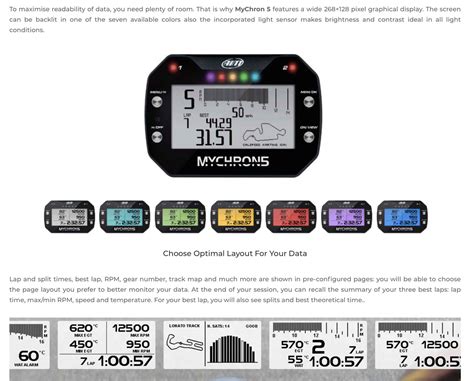

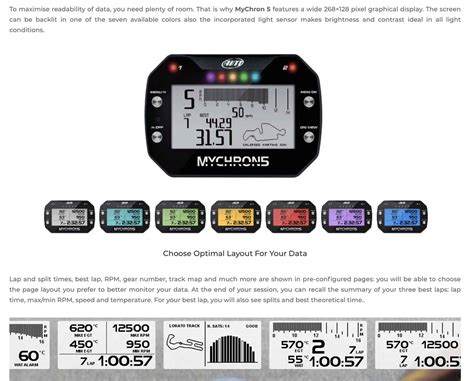

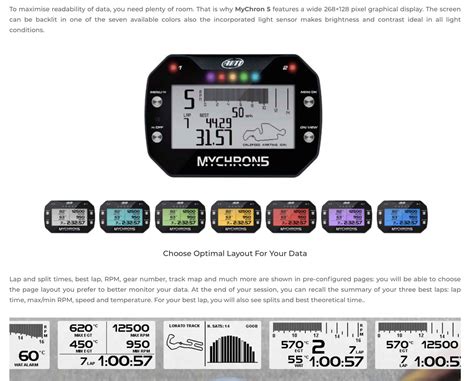

The Mychron 5 is a popular data logging system used in various forms of motorsport, providing valuable insights into a driver's performance and the vehicle's behavior on track. One of the key aspects of utilizing the Mychron 5 to its full potential is the ability to customize and enhance its functionality, which can be achieved through the use of STL files for 3D printing custom covers or mounts. In this article, we will delve into the importance of STL files, the process of downloading and utilizing them for the Mychron 5, and the benefits of customizing your data logging system.

The Mychron 5, with its advanced features such as GPS, accelerometer, and data analysis software, has become an indispensable tool for drivers seeking to improve their lap times and overall racing performance. However, like any piece of equipment, it can be subject to wear and tear, especially in the high-stress environment of a racing car. Custom covers or protective casings can offer enhanced durability and protection against the elements or physical damage. This is where STL files come into play, providing the digital blueprint for creating these custom parts through 3D printing.

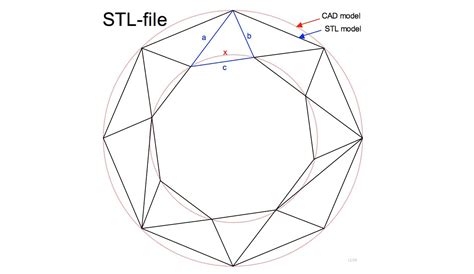

Understanding STL Files

STL (STereoLithography) files are widely used in 3D printing for their ability to describe the surface geometry of a 3D object without any color, texture, or other common CAD model attributes. They are essential for creating the physical models from digital data, making them a crucial component in the design and manufacturing process of custom parts for the Mychron 5. The process of creating an STL file involves CAD (Computer-Aided Design) software, where designers model the desired part, such as a custom cover for the Mychron 5, and then export it in STL format for 3D printing.

Benefits of Customizing the Mychron 5 with STL Files

Customizing the Mychron 5 using STL files offers several benefits, including enhanced protection, improved durability, and the ability to tailor the device to specific racing needs. For instance, a custom cover can be designed to fit perfectly around the Mychron 5, protecting it from dust, moisture, and physical impacts that could otherwise damage the device. Additionally, customization allows for the integration of specific features or mounts that can enhance the usability of the Mychron 5 in different racing environments.

Downloading and Using STL Files for the Mychron 5

The process of downloading and using STL files for the Mychron 5 involves several steps. First, locating a reliable source for the STL files is crucial. This could be through online repositories that specialize in 3D printing models or directly from manufacturers who provide custom designs for their products. Once the appropriate STL file is downloaded, it needs to be prepared for 3D printing, which may involve slicing the model into layers and configuring the printing settings. The final step is the actual 3D printing of the custom part, which requires a 3D printer capable of handling the chosen material and the complexity of the design.

Steps for 3D Printing a Custom Mychron 5 Cover

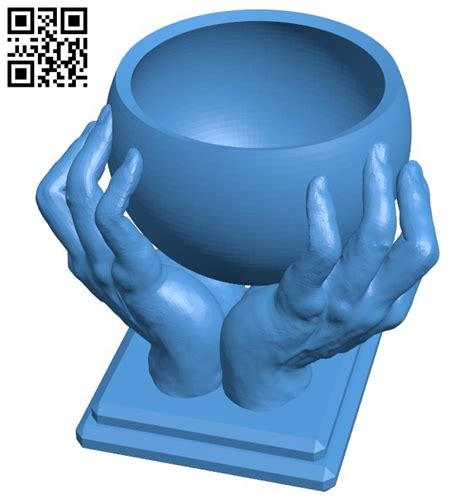

The steps for 3D printing a custom Mychron 5 cover include:

- **Designing the Cover**: Using CAD software to create a digital model of the cover, taking into account the dimensions of the Mychron 5 and any specific features required.

- **Exporting the STL File**: Once the design is complete, exporting it as an STL file for 3D printing.

- **Preparing for Print**: Slicing the STL file into printable layers and configuring the print settings such as material, infill density, and support structures.

- **3D Printing**: Loading the prepared file into the 3D printer and initiating the print job.

- **Post-processing**: Removing the printed cover from the printer, removing any support structures, and applying a finish if necessary.

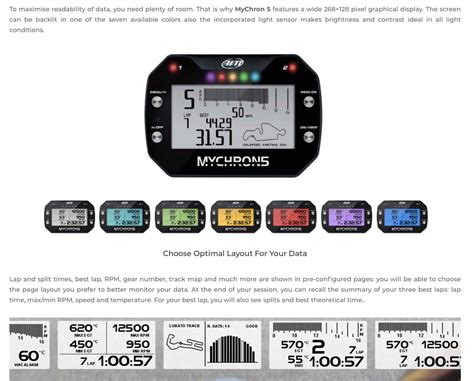

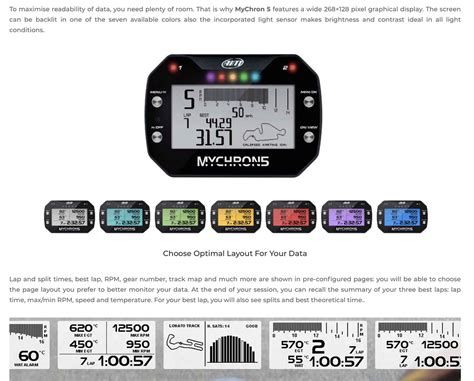

Gallery of Mychron 5 Customization Ideas

Mychron 5 Customization Ideas Gallery

Conclusion and Future Directions

In conclusion, the use of STL files for customizing the Mychron 5 offers a wide range of possibilities for enhancing its functionality and durability. As 3D printing technology continues to evolve, we can expect to see even more innovative and complex designs that push the boundaries of what is possible with data logging systems in motorsport. Whether you are a professional driver or an enthusiast, exploring the world of custom STL files can open up new avenues for improving your racing performance and protecting your valuable equipment.

We invite you to share your experiences with customizing the Mychron 5 or any other data logging systems using STL files. Have you designed and printed your own custom covers or mounts? What benefits have you seen from customization, and what challenges have you faced? Your insights can help others in the racing community to better utilize this technology and take their performance to the next level. Feel free to comment below, and don't forget to share this article with anyone who might be interested in exploring the potential of STL files for their Mychron 5 or other racing equipment.