Intro

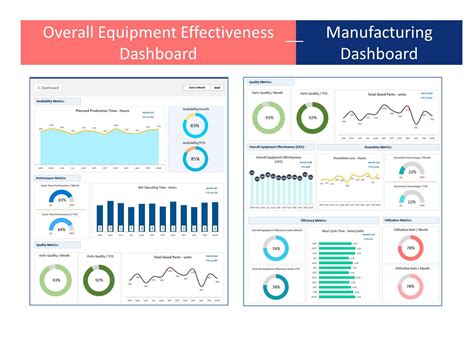

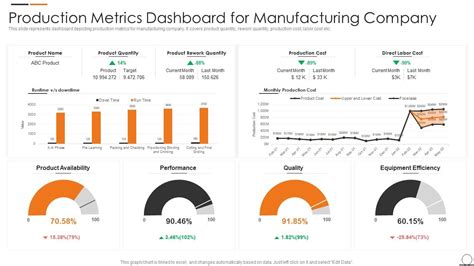

Boost your Overall Equipment Effectiveness (OEE) with a free Excel dashboard template. Discover 5 actionable strategies to optimize production, reduce downtime, and increase efficiency. Learn how to track key performance indicators (KPIs), identify bottlenecks, and make data-driven decisions to improve manufacturing productivity and reduce costs.

Improving Overall Equipment Effectiveness (OEE) is a key strategy for manufacturing companies to increase productivity, reduce waste, and enhance profitability. OEE is a metric that measures the effectiveness of equipment in terms of its ability to produce quality products at maximum capacity. Boosting OEE requires a combination of strategic planning, data analysis, and continuous improvement. In this article, we will discuss five ways to boost OEE using a free Excel dashboard template.

Understanding OEE

Before we dive into the strategies for boosting OEE, it's essential to understand the concept of OEE. OEE is calculated by multiplying three main components:

- Availability: The percentage of time equipment is available for production.

- Performance: The rate at which equipment produces products compared to its maximum capacity.

- Quality: The percentage of products produced that meet quality standards.

OEE = Availability x Performance x Quality

5 Ways to Boost OEE with Free Excel Dashboard Template

Here are five strategies to improve OEE using a free Excel dashboard template:

1. Monitor and Analyze Equipment Performance

Monitoring and analyzing equipment performance is crucial to identifying areas for improvement. A free Excel dashboard template can help you track equipment performance metrics such as:

- Availability: Track the percentage of time equipment is available for production.

- Performance: Monitor the rate at which equipment produces products compared to its maximum capacity.

- Quality: Track the percentage of products produced that meet quality standards.

By analyzing these metrics, you can identify bottlenecks and areas for improvement.

Step-by-Step Instructions

- Download a free Excel dashboard template.

- Enter equipment performance data into the template.

- Analyze the data to identify areas for improvement.

- Develop a plan to address bottlenecks and improve equipment performance.

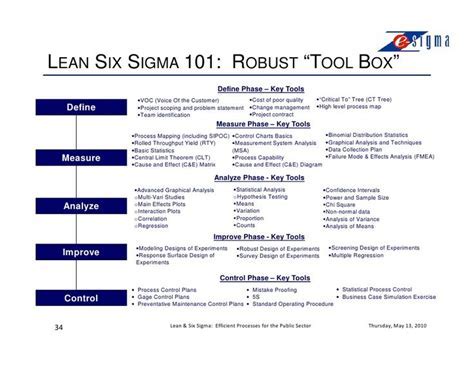

2. Implement Total Productive Maintenance (TPM)

TPM is a maintenance strategy that involves operators in maintenance activities to improve equipment reliability and reduce downtime. Implementing TPM can help improve equipment availability and performance.

Step-by-Step Instructions

- Develop a TPM plan that involves operators in maintenance activities.

- Train operators on maintenance procedures.

- Implement a schedule for regular maintenance activities.

- Monitor and analyze TPM metrics using a free Excel dashboard template.

3. Improve Operator Training and Engagement

Operator training and engagement are critical to improving equipment performance and quality. Providing operators with the necessary training and resources can help improve their productivity and efficiency.

Step-by-Step Instructions

- Develop a training plan for operators.

- Provide operators with the necessary resources and support.

- Encourage operator engagement and feedback.

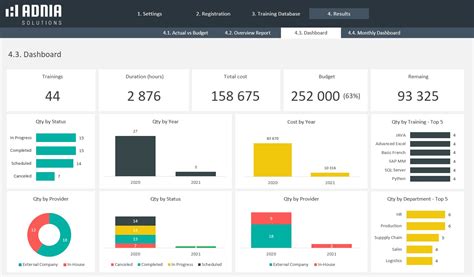

- Monitor and analyze operator training metrics using a free Excel dashboard template.

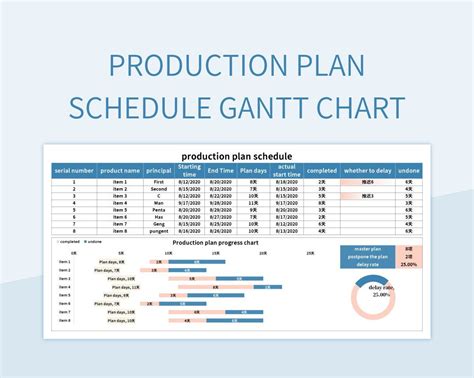

4. Optimize Production Planning and Scheduling

Optimizing production planning and scheduling can help improve equipment performance and reduce downtime. Using a free Excel dashboard template can help you analyze production planning and scheduling metrics such as:

- Production schedule: Track production schedules to ensure equipment is utilized efficiently.

- Equipment utilization: Monitor equipment utilization to identify areas for improvement.

- Downtime: Track downtime to identify causes and develop strategies for reduction.

Step-by-Step Instructions

- Analyze production planning and scheduling metrics using a free Excel dashboard template.

- Develop a plan to optimize production planning and scheduling.

- Implement changes to production planning and scheduling.

- Monitor and analyze the impact of changes on equipment performance.

5. Continuously Monitor and Improve OEE

Continuously monitoring and improving OEE is critical to achieving long-term success. Using a free Excel dashboard template can help you track OEE metrics and identify areas for improvement.

Step-by-Step Instructions

- Monitor OEE metrics using a free Excel dashboard template.

- Analyze OEE data to identify areas for improvement.

- Develop a plan to improve OEE.

- Implement changes to improve OEE.

- Continuously monitor and analyze OEE metrics.

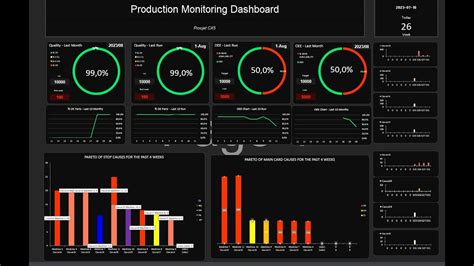

Gallery of OEE and Manufacturing Improvement

OEE and Manufacturing Improvement Image Gallery

Conclusion

Boosting OEE requires a combination of strategic planning, data analysis, and continuous improvement. Using a free Excel dashboard template can help you track OEE metrics and identify areas for improvement. By implementing the strategies outlined in this article, you can improve equipment performance, reduce downtime, and enhance profitability.