Intro

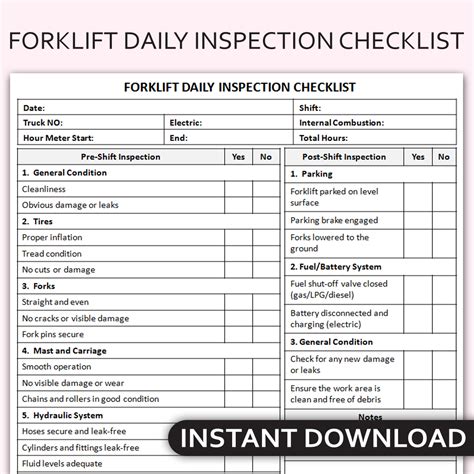

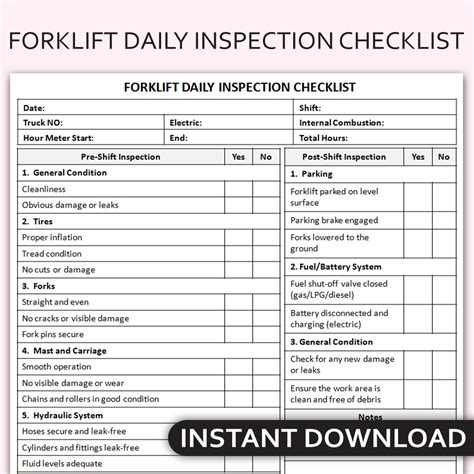

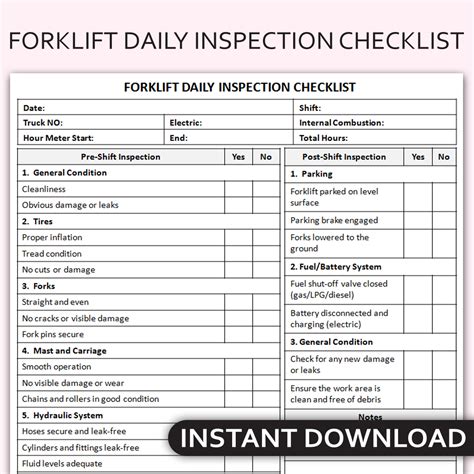

Ensure forklift safety and compliance with our free, downloadable weekly forklift inspection checklist template. Streamline your maintenance routine and identify potential hazards with this comprehensive template, covering critical areas such as tires, brakes, hydraulic systems, and operator safety, helping you prevent accidents and maintain OSHA standards.

Maintaining the safety and efficiency of forklift operations is crucial in any warehouse or manufacturing setting. A key aspect of this maintenance is regular inspections, which help identify potential issues before they become major problems. A forklift inspection checklist is a valuable tool for ensuring that your forklifts are in good working condition. Here, we'll delve into the importance of weekly forklift inspections and provide a comprehensive template for your use.

Why Weekly Forklift Inspections Matter

Weekly forklift inspections are essential for several reasons:

- Safety: Regular inspections can help prevent accidents by identifying and addressing potential safety hazards.

- Productivity: Ensuring that forklifts are in good working condition can reduce downtime and increase productivity.

- Cost Savings: Regular maintenance can extend the lifespan of your forklifts and reduce repair costs.

- Regulatory Compliance: Regular inspections can help ensure compliance with regulatory requirements.

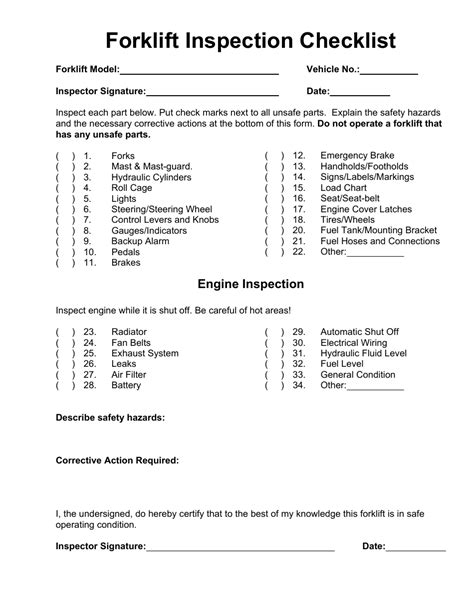

Pre-Operational Inspection

Pre-Operational Inspection

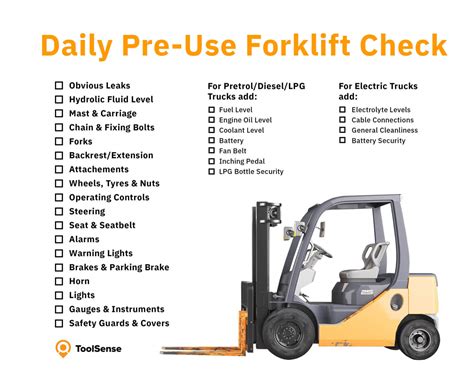

Before each use, operators should perform a pre-operational inspection to ensure the forklift is safe to operate. This includes:

Operator Checks

- Ensure all operators are properly trained and authorized to use the forklift.

- Operators should wear appropriate personal protective equipment (PPE) such as safety shoes and a safety vest.

- Operators should review the forklift's operational manual and be familiar with its controls and functions.

Forklift Checks

- Fuel and Fluid Levels: Check the levels of fuel, hydraulic fluid, and engine oil. Top off fluids as needed.

- Battery Condition: Inspect the battery for signs of damage or corrosion. Check the electrolyte level and charge the battery if necessary.

- Tires: Inspect the tires for signs of wear, damage, or improper inflation.

- Lights and Alarms: Check the functioning of headlights, taillights, and backup alarms.

- Mirrors and Visibility: Ensure that all mirrors are clean and free of damage, providing a clear view of the surroundings.

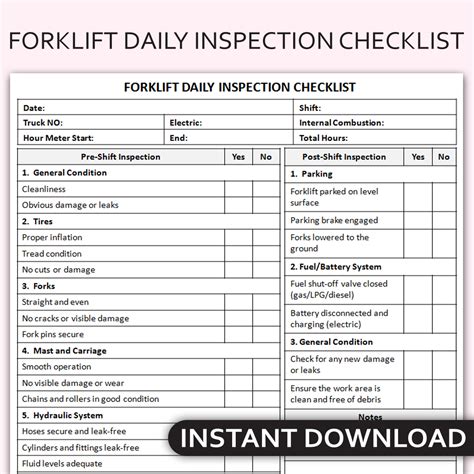

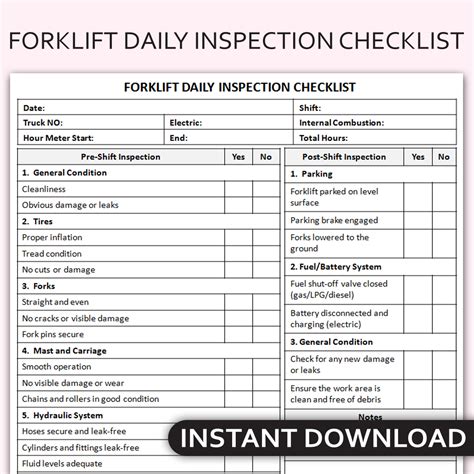

Daily Inspection

Daily Inspection

In addition to pre-operational checks, operators should perform a daily inspection to catch any issues that may have arisen during use. This includes:

Safety Checks

- Safety Labels and Signs: Ensure that all safety labels and signs are in place and legible.

- Safety Features: Check the operation of safety features such as the seatbelt and horn.

- Warning Devices: Ensure that all warning devices such as backup alarms and lights are functioning correctly.

Operational Checks

- Lift and Lower Functions: Test the lift and lower functions to ensure they are working properly.

- Hydraulic Leaks: Inspect for hydraulic leaks around cylinders, hoses, and connections.

- Forks and Attachments: Check the condition of forks and any attachments, ensuring they are securely attached and free of damage.

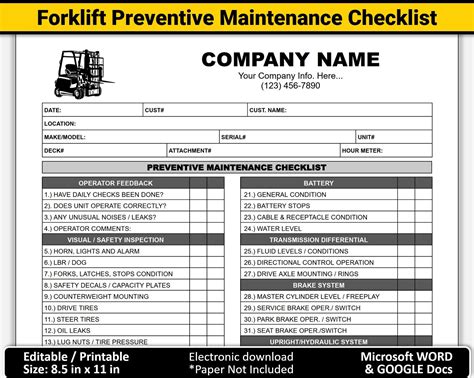

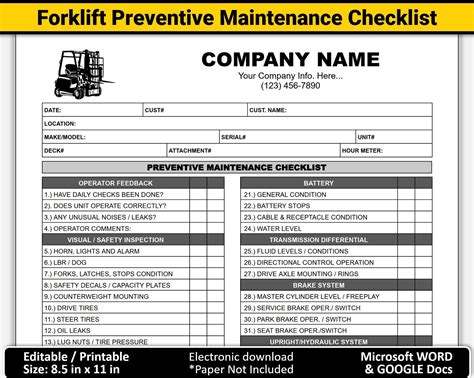

Weekly Inspection

Weekly Inspection

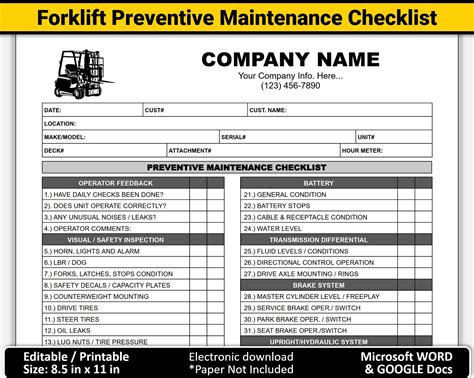

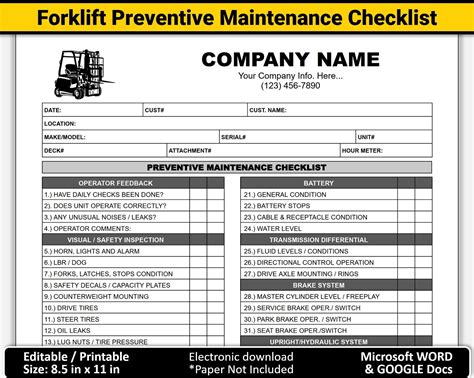

A weekly inspection should be performed by a qualified mechanic or supervisor to address more in-depth issues. This includes:

Detailed Safety Checks

- Safety Guard and Cage: Inspect the safety guard and cage for signs of damage or wear.

- Seat and Seatbelt: Check the condition of the seat and seatbelt, ensuring they are securely attached and in good condition.

Detailed Operational Checks

- Engine and Transmission: Inspect the engine and transmission for signs of leaks or damage.

- Electrical System: Check the condition of electrical components such as wiring, fuses, and relays.

- Braking System: Test the braking system to ensure it is functioning correctly.

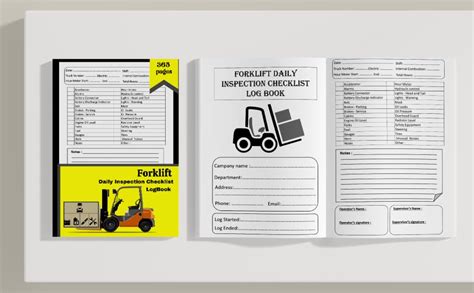

Record Keeping

Record Keeping

Accurate record keeping is essential for tracking inspections, maintenance, and repairs. This includes:

- Inspection Records: Keep detailed records of all inspections, including the date, time, and results.

- Maintenance Records: Record all maintenance activities, including routine maintenance and repairs.

- Repair Records: Keep detailed records of all repairs, including the date, time, and description of the work performed.

Training and Familiarization

Training and Familiarization

Operators should receive comprehensive training on the forklift's operation, safety features, and maintenance requirements. This includes:

- Operational Training: Provide detailed training on the forklift's operational controls and functions.

- Safety Training: Emphasize the importance of safety features and procedures.

- Maintenance Training: Teach operators basic maintenance tasks and troubleshooting techniques.

Conclusion: Embracing Regular Forklift Inspections

Regular forklift inspections are crucial for ensuring the safety and efficiency of your warehouse operations. By implementing a comprehensive inspection program, you can reduce the risk of accidents, extend the lifespan of your forklifts, and maintain regulatory compliance. Remember, safety and productivity go hand-in-hand; prioritize both with regular inspections.

Call to Action

- Share your experiences with forklift inspections and how they've improved your operations.

- What challenges do you face in maintaining your forklifts, and how do you address them?

- Consider implementing a forklift inspection checklist in your daily operations and observe the improvements.

Gallery of Forklift Inspection Templates

Forklift Inspection Templates Gallery

By implementing these measures, you can ensure that your forklifts are running safely and efficiently, contributing to a productive and safe work environment.