Intro

Heat press machines have revolutionized the world of heat transfer, making it easier to create custom designs, logos, and images on various materials. One of the most critical factors in achieving professional-looking results is temperature control. In this article, we will delve into the essential heat press temperature settings that every crafty entrepreneur, hobbyist, or DIY enthusiast should know.

The importance of heat press temperature settings cannot be overstated. Incorrect temperature settings can lead to subpar results, wasted materials, and even damaged equipment. By understanding the optimal temperature ranges for different materials, you can ensure that your heat transfers are of the highest quality, every time.

In this comprehensive guide, we will explore the 7 essential heat press temperature settings for common materials, along with expert tips and tricks for achieving perfect results.

Understanding Heat Press Temperature Basics

Before we dive into the specific temperature settings, it's essential to understand the basics of heat press temperature control. Heat press machines work by applying heat and pressure to transfer ink or other materials onto a substrate. The temperature setting controls the amount of heat applied during the transfer process.

Most heat press machines have a temperature range of around 200°F to 400°F (90°C to 200°C), with some high-end models reaching temperatures of up to 500°F (260°C). The ideal temperature setting depends on the material being transferred, the type of ink or transfer medium, and the desired result.

Temperature Settings for Common Materials

Here are the 7 essential heat press temperature settings for common materials:

-

Cotton and Polyester Blends: 350°F (175°C) to 375°F (190°C) Cotton and polyester blends are one of the most common materials used in heat transfer. For optimal results, set the temperature between 350°F (175°C) and 375°F (190°C).

-

Nylon and Spandex: 325°F (165°C) to 350°F (175°C) Nylon and spandex materials require a slightly lower temperature range to prevent scorching or damage. Set the temperature between 325°F (165°C) and 350°F (175°C) for best results.

-

Leather and Suede: 275°F (135°C) to 300°F (150°C) Leather and suede materials are more delicate and require a lower temperature range to prevent damage. Set the temperature between 275°F (135°C) and 300°F (150°C) for optimal results.

-

Ceramic and Glass: 400°F (200°C) to 425°F (220°C) Ceramic and glass materials require a higher temperature range to ensure a strong bond between the transfer and the substrate. Set the temperature between 400°F (200°C) and 425°F (220°C) for best results.

-

Metal and Plastic: 375°F (190°C) to 400°F (200°C) Metal and plastic materials require a medium to high temperature range to ensure a strong bond between the transfer and the substrate. Set the temperature between 375°F (190°C) and 400°F (200°C) for optimal results.

-

Wood and Paper: 325°F (165°C) to 350°F (175°C) Wood and paper materials are more delicate and require a lower temperature range to prevent damage. Set the temperature between 325°F (165°C) and 350°F (175°C) for best results.

-

Sublimation: 400°F (200°C) to 425°F (220°C) Sublimation is a specialized heat transfer process that requires a high temperature range to ensure a strong bond between the transfer and the substrate. Set the temperature between 400°F (200°C) and 425°F (220°C) for optimal results.

Tips and Tricks for Achieving Perfect Results

Here are some expert tips and tricks for achieving perfect results with your heat press machine:

- Always pre-press your materials to remove any wrinkles or air pockets.

- Use a temperature gun to ensure accurate temperature readings.

- Experiment with different temperature settings to find the optimal range for your specific material.

- Use a heat-resistant tape to secure your materials during the transfer process.

- Always follow the manufacturer's instructions for the specific material you are working with.

Common Mistakes to Avoid

Here are some common mistakes to avoid when working with heat press machines:

- Setting the temperature too high or too low, resulting in subpar results.

- Not pre-pressing materials, resulting in wrinkles or air pockets.

- Not using a temperature gun, resulting in inaccurate temperature readings.

- Not following the manufacturer's instructions, resulting in damaged materials or equipment.

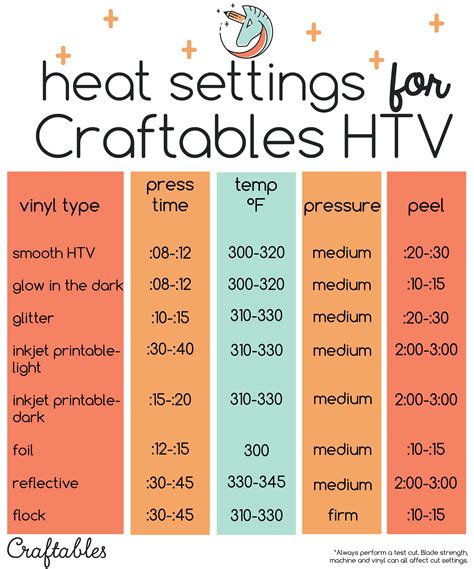

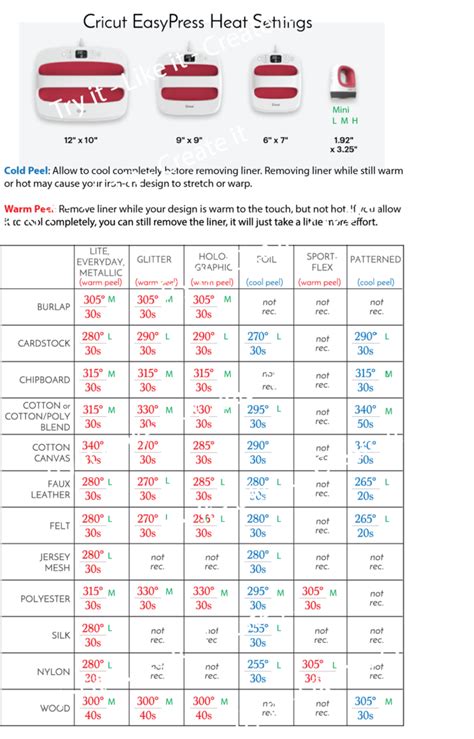

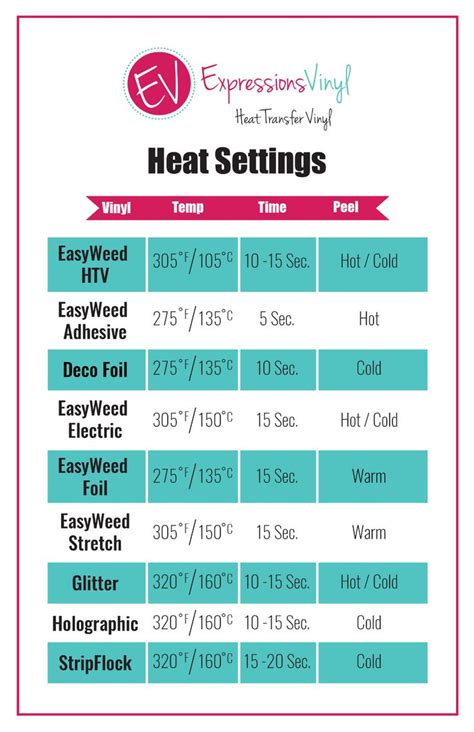

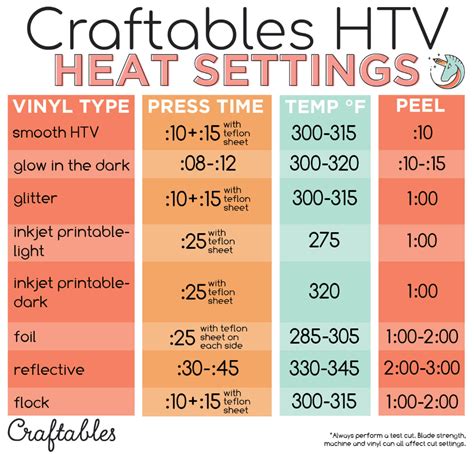

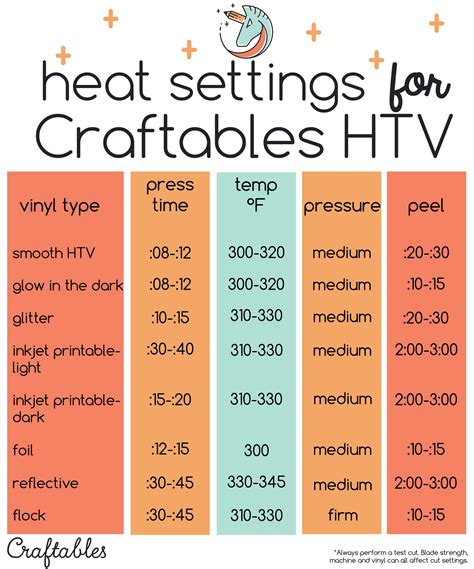

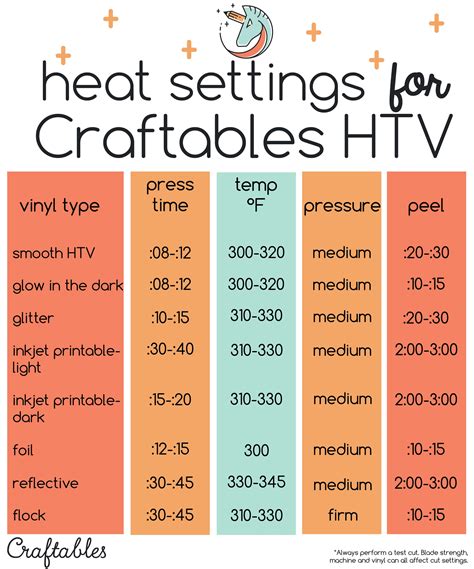

Gallery of Heat Press Temperature Settings

Heat Press Temperature Settings Image Gallery

In conclusion, mastering the art of heat press temperature control is crucial for achieving professional-looking results. By understanding the essential temperature settings for common materials and following expert tips and tricks, you can ensure that your heat transfers are of the highest quality, every time. Whether you're a crafty entrepreneur, hobbyist, or DIY enthusiast, this guide has provided you with the knowledge and expertise to take your heat press game to the next level.