Mastering production capacity planning is crucial for businesses to optimize their resources, reduce waste, and increase productivity. One of the most effective tools for production capacity planning is Microsoft Excel. With its robust features and user-friendly interface, Excel can help you streamline your production process and make informed decisions. In this article, we will share 7 tips to master production capacity planning in Excel.

Understanding the Basics of Production Capacity Planning

Before we dive into the tips, it's essential to understand the basics of production capacity planning. Production capacity planning is the process of determining the maximum amount of production that can be achieved by a business within a given period. It involves analyzing various factors such as production capacity, demand, and resource availability to ensure that the business can meet customer demand without overextending its resources.

Why Excel is Ideal for Production Capacity Planning

Excel is an ideal tool for production capacity planning due to its robust features and flexibility. With Excel, you can create complex models, track data, and analyze performance metrics. Additionally, Excel's intuitive interface makes it easy to use, even for those without extensive technical expertise.

Tips to Master Production Capacity Planning in Excel

Tip 1: Define Your Production Capacity

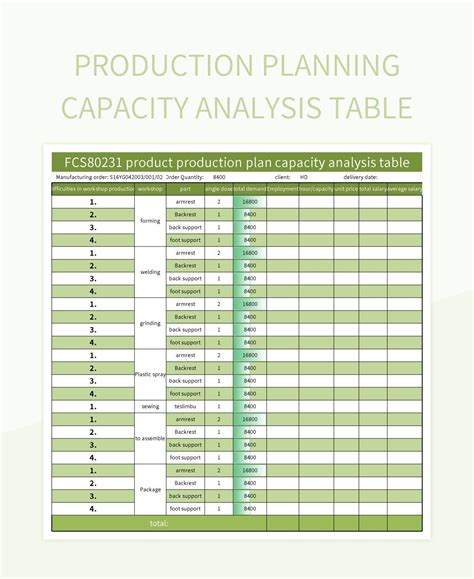

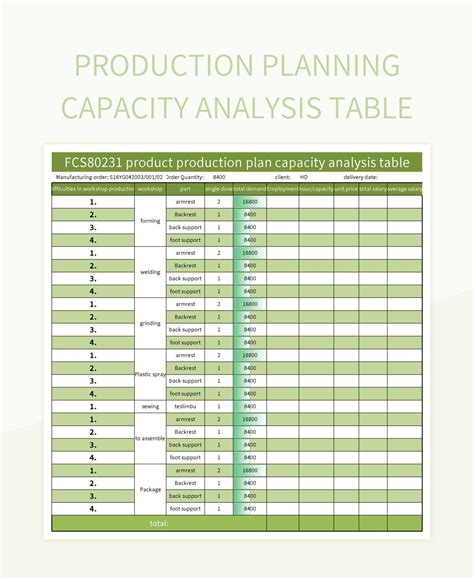

The first step in mastering production capacity planning in Excel is to define your production capacity. This involves calculating the maximum amount of production that your business can achieve within a given period. You can use Excel's formulas and functions to calculate your production capacity based on factors such as machine hours, labor hours, and material availability.

Tip 2: Track Demand and Forecast Sales

Tracking demand and forecasting sales is crucial for production capacity planning. You can use Excel's charts and graphs to track demand and identify trends. Additionally, you can use Excel's forecasting functions to predict future sales based on historical data.

Tip 3: Create a Production Schedule

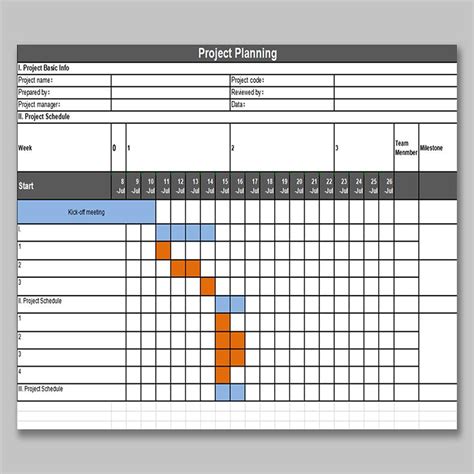

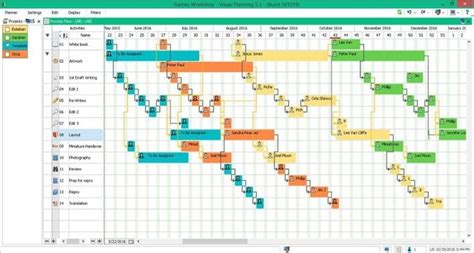

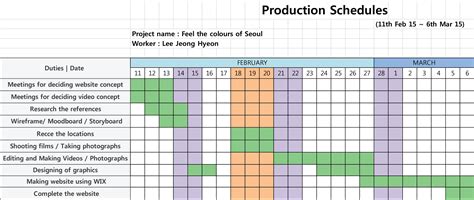

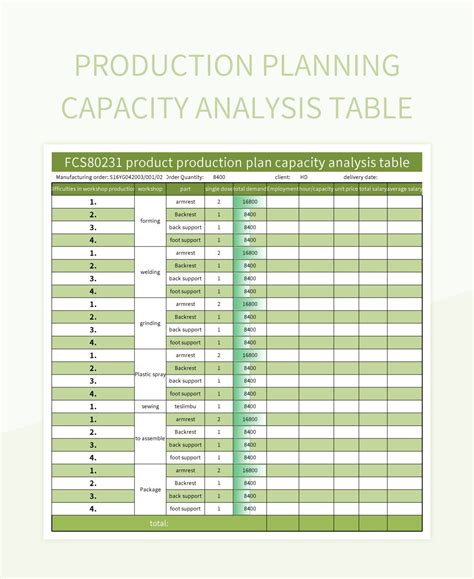

A production schedule is a critical component of production capacity planning. You can use Excel's tables and formulas to create a production schedule that outlines the production process, including start and end dates, production quantities, and resource allocation.

Tip 4: Analyze Resource Availability

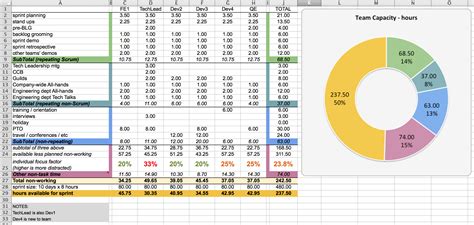

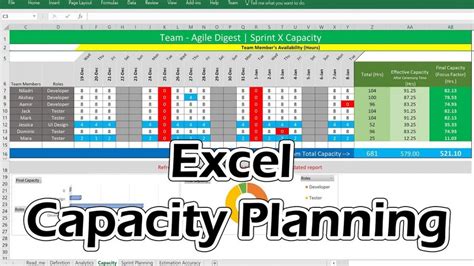

Resource availability is a critical factor in production capacity planning. You can use Excel's formulas and functions to analyze resource availability, including machine hours, labor hours, and material availability.

Tip 5: Identify Bottlenecks and Constraints

Identifying bottlenecks and constraints is essential for production capacity planning. You can use Excel's analysis tools to identify bottlenecks and constraints in the production process, including machine downtime, labor shortages, and material scarcity.

Tip 6: Monitor and Adjust

Monitoring and adjusting your production capacity plan is crucial for ensuring that your business can meet customer demand without overextending its resources. You can use Excel's dashboards and reports to monitor performance metrics and adjust your production capacity plan as needed.

Tip 7: Use Excel's Advanced Features

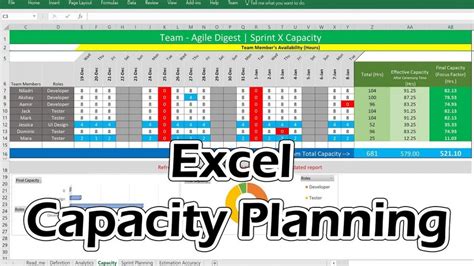

Finally, use Excel's advanced features, such as macros and pivot tables, to streamline your production capacity planning process. With macros, you can automate repetitive tasks, while pivot tables can help you analyze large datasets and identify trends.

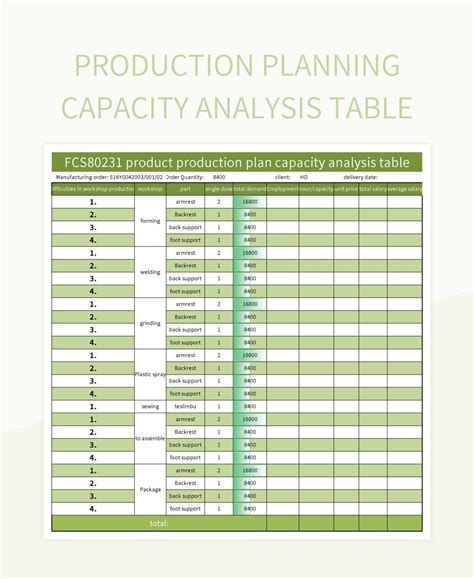

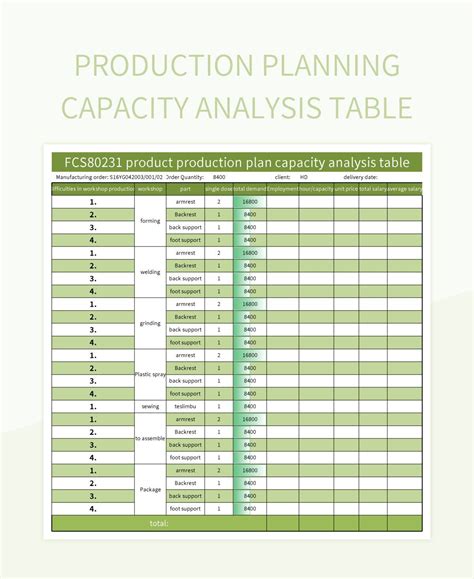

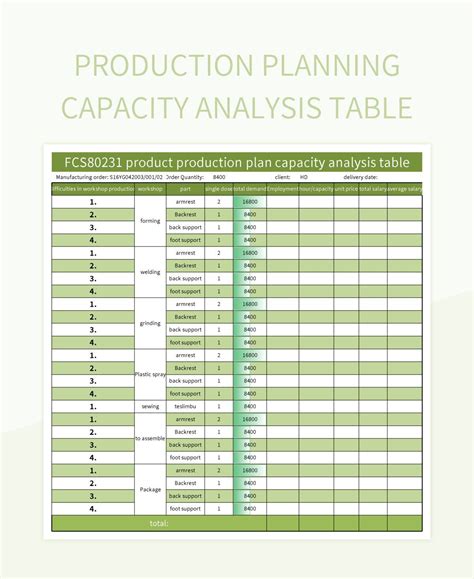

Gallery of Production Capacity Planning in Excel

Production Capacity Planning in Excel Image Gallery

Mastering Production Capacity Planning in Excel: Conclusion

Mastering production capacity planning in Excel requires a deep understanding of the basics of production capacity planning, as well as the use of Excel's advanced features. By following the 7 tips outlined in this article, you can create a robust production capacity plan that helps your business optimize its resources, reduce waste, and increase productivity. Remember to track demand and forecast sales, create a production schedule, analyze resource availability, identify bottlenecks and constraints, monitor and adjust, and use Excel's advanced features to streamline your production capacity planning process.

We hope this article has provided you with valuable insights and practical tips to master production capacity planning in Excel. If you have any questions or comments, please feel free to share them below.