Master the art of sheet metal worker welding jobs with these 5 expert tips. Discover techniques for precision welding, boosting productivity, and ensuring safety protocols. Learn how to handle metal fabrication, mig welding, and fabrication techniques to excel in the industry and secure high-paying welding jobs.

As a sheet metal worker, welding is an essential skill that can make or break your career. Whether you're working on a construction site, in a factory, or in a small workshop, the ability to weld safely and effectively is crucial to producing high-quality results. In this article, we'll explore five tips for sheet metal worker welding jobs that can help you improve your skills, stay safe, and succeed in your career.

Understanding the Basics of Welding

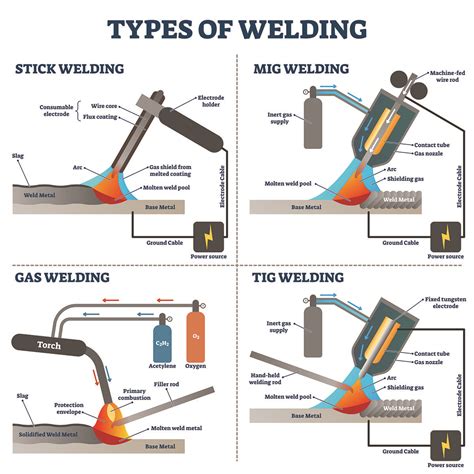

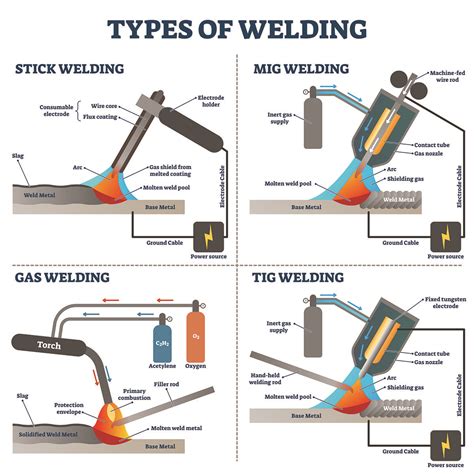

Before we dive into the tips, it's essential to understand the basics of welding. Welding is a process that joins two metal pieces together by applying heat, pressure, or both. There are several types of welding, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW). Each type of welding requires different equipment, techniques, and safety precautions.

Tip 1: Choose the Right Welding Equipment

The right welding equipment can make a huge difference in the quality of your work. As a sheet metal worker, you'll likely use a variety of welding machines, including MIG, TIG, and arc welders. When choosing a welding machine, consider the type of metal you'll be working with, the thickness of the metal, and the level of precision required. It's also essential to choose a machine that is easy to use and maintain.

Tip 2: Practice Safety Precautions

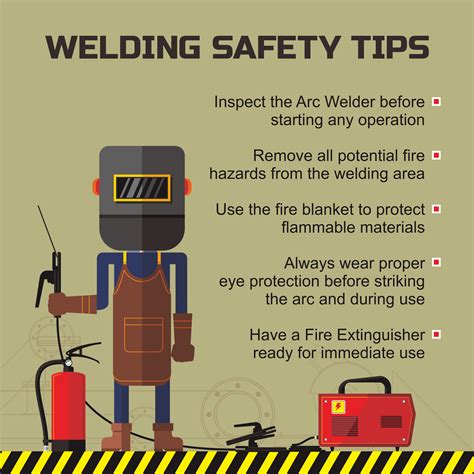

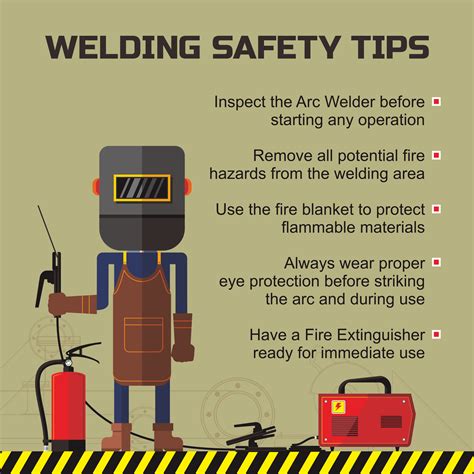

Welding can be a hazardous activity, especially when working with sheet metal. To stay safe, always wear protective gear, including a welding helmet, gloves, and safety glasses. Make sure the area is well-ventilated, and avoid wearing loose clothing that could catch fire. It's also essential to follow proper welding techniques to avoid injuries and ensure high-quality results.

Tip 3: Master the Art of Welding Techniques

There are several welding techniques that you'll need to master as a sheet metal worker, including the push technique, the pull technique, and the weave technique. Practice these techniques on scrap metal before working on actual projects. It's also essential to understand the different types of welds, including the butt weld, the lap weld, and the corner weld.

Tip 4: Pay Attention to Metal Preparation

Proper metal preparation is crucial to producing high-quality welds. Make sure the metal is clean and free of debris, and use a wire brush to remove any rust or corrosion. Use a metal conditioner to remove any oxidation, and ensure the metal is properly aligned before welding.

Tip 5: Continuously Improve Your Skills

Finally, it's essential to continuously improve your welding skills as a sheet metal worker. Take courses, attend workshops, and practice new techniques to stay up-to-date with the latest welding technologies. Join online forums and communities to connect with other welders and learn from their experiences.

Sheet Metal Worker Welding Jobs: Conclusion

In conclusion, sheet metal worker welding jobs require a combination of technical skills, attention to safety, and continuous learning. By following these five tips, you can improve your welding skills, stay safe, and succeed in your career. Remember to choose the right welding equipment, practice safety precautions, master the art of welding techniques, pay attention to metal preparation, and continuously improve your skills.

Sheet Metal Worker Welding Jobs Image Gallery

We hope this article has provided you with valuable tips and insights to improve your sheet metal worker welding jobs. Share your thoughts and experiences in the comments below, and don't forget to share this article with your friends and colleagues.