Boost your workflow efficiency with these 5 expert ways to speed up Titanium development. Discover how to optimize your code, streamline your workflow, and accelerate your app building process. Learn the secrets to faster Titanium development, including tips on modularizing code, leveraging frameworks, and harnessing the power of automation.

Speeding out titanium can be a challenging task, but there are several techniques that can help. Whether you're a machinist, engineer, or manufacturer, understanding how to efficiently work with titanium is crucial for achieving successful results. Here are five ways to speed out titanium.

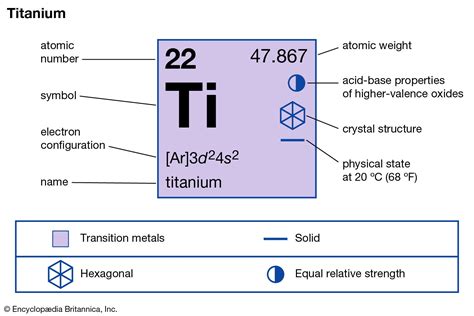

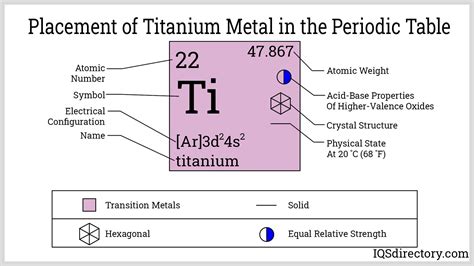

Understanding Titanium Properties

Before we dive into the techniques, it's essential to understand the properties of titanium. Titanium is a strong, lightweight metal with a high strength-to-weight ratio, making it an ideal material for aerospace, medical, and industrial applications. However, its unique properties also make it challenging to work with. Titanium has a high reactivity, which can lead to galling and corrosion, and its low thermal conductivity makes it difficult to dissipate heat during machining.

1. High-Speed Machining

High-speed machining (HSM) is a technique that uses high spindle speeds and feed rates to quickly remove material from titanium parts. This method can be effective for speeding out titanium, but it requires specialized equipment and tooling. HSM involves using a high-speed spindle, typically above 10,000 RPM, and a feed rate of 100-200 mm/min. The high speed and feed rate help to reduce the heat generated during machining, which can improve surface finish and reduce tool wear.

Benefits of High-Speed Machining

- Improved surface finish

- Reduced tool wear

- Increased productivity

- Better dimensional accuracy

2. Using the Right Cutting Tools

Using the right cutting tools is crucial for speeding out titanium. Titanium is a reactive metal, which means it can easily gall and corrode when in contact with other metals. To mitigate this, use cutting tools made from materials that are resistant to titanium, such as tungsten carbide or cubic boron nitride (CBN). These materials have a low reactivity with titanium, which reduces the risk of galling and corrosion.

Types of Cutting Tools for Titanium

- Tungsten carbide (WC)

- Cubic boron nitride (CBN)

- Diamond-coated tools

- Solid carbide tools

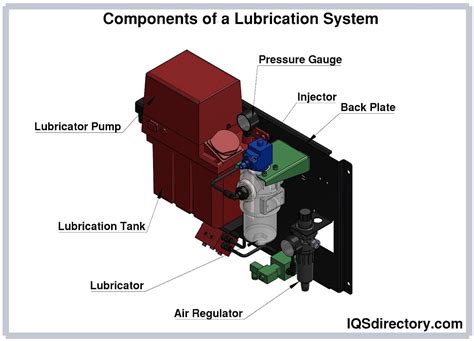

3. Cooling and Lubrication Systems

Cooling and lubrication systems play a critical role in speeding out titanium. Titanium machining generates high temperatures, which can lead to tool wear and reduce the quality of the surface finish. A cooling system helps to dissipate heat and reduce the temperature of the cutting tool and workpiece. A lubrication system, on the other hand, helps to reduce friction and prevent galling.

Types of Cooling and Lubrication Systems

- Flood cooling

- Mist cooling

- Dry machining

- Minimum quantity lubrication (MQL)

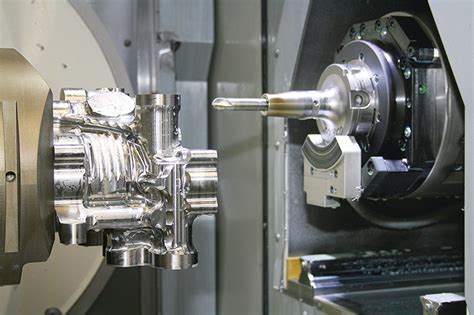

4. Titanium Machining Centers

Titanium machining centers are specialized machines designed specifically for machining titanium. These machines typically have high-speed spindles, advanced cooling systems, and specialized tooling. They are designed to optimize the machining process for titanium, which can help to speed out the material.

Features of Titanium Machining Centers

- High-speed spindles

- Advanced cooling systems

- Specialized tooling

- Optimized machining parameters

5. Advanced Machining Techniques

Advanced machining techniques, such as grinding, electrical discharge machining (EDM), and laser machining, can be used to speed out titanium. These techniques use non-traditional methods to remove material, which can help to improve surface finish and reduce tool wear.

Types of Advanced Machining Techniques

- Grinding

- Electrical discharge machining (EDM)

- Laser machining

- Water jet machining

Titanium Machining Techniques Image Gallery

By understanding these five techniques for speeding out titanium, machinists, engineers, and manufacturers can improve their productivity, reduce tool wear, and achieve better surface finishes. Remember to always use the right cutting tools, cooling and lubrication systems, and machining parameters to optimize the machining process for titanium.