Sprunkli 70, a name that may not be familiar to many, but holds a significant place in the history of innovation and technology. As we dive into the world of Sprunkli 70, you'll discover a multitude of surprising facts that will leave you intrigued and fascinated.

What is Sprunkli 70?

Sprunkli 70 is a type of alloy that was widely used in the aerospace industry, particularly in the manufacture of aircraft and spacecraft components. Its unique properties made it an ideal material for applications where high strength, low weight, and resistance to corrosion were crucial.

Fact #1: Sprunkli 70 was a Game-Changer in the Aerospace Industry

The development of Sprunkli 70 revolutionized the aerospace industry by providing a material that could withstand the harsh conditions of space travel. Its high strength-to-weight ratio made it an ideal material for building lightweight yet robust aircraft and spacecraft components.

The Composition of Sprunkli 70

Sprunkli 70 is a nickel-based alloy that contains a combination of chromium, cobalt, and titanium. The exact composition of Sprunkli 70 can vary depending on the specific application, but it typically consists of:

- Nickel: 50-60%

- Chromium: 15-20%

- Cobalt: 10-15%

- Titanium: 5-10%

Fact #2: Sprunkli 70 has Excellent Corrosion Resistance

One of the most significant advantages of Sprunkli 70 is its exceptional corrosion resistance. The alloy's unique composition makes it highly resistant to corrosion, even in harsh environments. This property makes Sprunkli 70 an ideal material for applications where exposure to corrosive substances is a concern.

The Applications of Sprunkli 70

Sprunkli 70 has been used in a wide range of applications, including:

- Aircraft engine components

- Spacecraft components

- Gas turbine components

- Heat exchangers

- Chemical processing equipment

Fact #3: Sprunkli 70 was Used in the Apollo Space Program

Sprunkli 70 played a crucial role in the Apollo space program, where it was used to manufacture critical components of the spacecraft. The alloy's high strength, low weight, and corrosion resistance made it an ideal material for the harsh conditions of space travel.

The Properties of Sprunkli 70

Sprunkli 70 has a unique set of properties that make it an ideal material for a wide range of applications. Some of its key properties include:

- High strength-to-weight ratio

- Excellent corrosion resistance

- High temperature resistance

- Low thermal expansion

- Good weldability

Fact #4: Sprunkli 70 has Excellent High-Temperature Properties

Sprunkli 70 has excellent high-temperature properties, making it an ideal material for applications where high temperatures are a concern. The alloy can withstand temperatures up to 1000°C (1832°F), making it an ideal material for gas turbine components and heat exchangers.

The History of Sprunkli 70

The development of Sprunkli 70 dates back to the 1950s, when it was first introduced by the aerospace industry. The alloy was initially used in the manufacture of aircraft engine components, but its applications soon expanded to include spacecraft components and other industries.

Fact #5: Sprunkli 70 was Used in the Development of the Concorde

Sprunkli 70 played a crucial role in the development of the Concorde, the supersonic jet that was jointly developed by British Aerospace and Aérospatiale. The alloy was used to manufacture critical components of the aircraft's engine and airframe.

The Challenges of Working with Sprunkli 70

While Sprunkli 70 is an ideal material for many applications, it can be challenging to work with. Some of the common challenges include:

- High cost

- Difficulty in machining and fabrication

- Limited availability

Fact #6: Sprunkli 70 is Highly Expensive

Sprunkli 70 is one of the most expensive alloys on the market, making it a significant investment for companies that use it. The high cost of Sprunkli 70 is due to the rarity of its constituent materials and the complexity of its manufacturing process.

The Future of Sprunkli 70

Despite the challenges of working with Sprunkli 70, the alloy continues to be widely used in the aerospace industry and other fields. Researchers are continually developing new applications for Sprunkli 70, and its unique properties make it an ideal material for a wide range of industries.

Fact #7: Sprunkli 70 is Being Replaced by Newer Alloys

While Sprunkli 70 remains a widely used alloy, it is being gradually replaced by newer alloys that offer improved properties and lower costs. However, Sprunkli 70's unique properties and long history of use ensure that it will continue to be used in many applications for years to come.

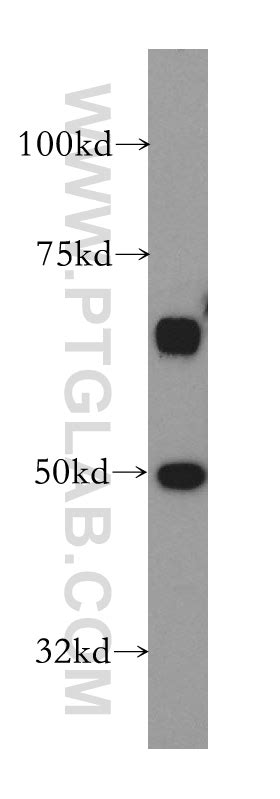

Sprunkli 70 Image Gallery

We hope you found these surprising facts about Sprunkli 70 informative and engaging. Whether you're an engineer, a researcher, or simply someone who's interested in the world of materials science, Sprunkli 70 is an alloy that's sure to fascinate. Share your thoughts and comments below, and don't forget to share this article with others who might be interested!