Discover the incredible secrets behind the SR-71 Blackbirds heat-resistant quartz windows. Learn about the innovative materials, manufacturing process, and remarkable properties that enabled these windows to withstand extreme temperatures and Mach 3+ speeds, making them a crucial component of the worlds fastest jet aircraft.

The SR-71 Blackbird, a supersonic reconnaissance plane developed by Lockheed Skunk Works, is an iconic symbol of innovation and engineering excellence. One of the most fascinating aspects of this aircraft is its use of quartz windows, which played a crucial role in its ability to gather intelligence at high speeds and altitudes. In this article, we will delve into seven amazing facts about the SR-71's quartz windows, exploring their unique properties, manufacturing process, and contributions to the aircraft's success.

1. Unique Properties of Quartz Windows

The SR-71's quartz windows were made from a specialized type of glass known as fused silica quartz, which offered exceptional optical clarity, strength, and thermal resistance. This material was chosen for its ability to withstand the extreme temperatures generated by the aircraft's high-speed flight, which could reach up to 2,000°F (1,093°C). The quartz windows were also designed to be extremely thin, measuring only about 1/4 inch (6 mm) in thickness, to minimize weight and reduce the risk of cracking or shattering.

Why Quartz Was the Perfect Choice

Quartz was the ideal material for the SR-71's windows due to its unique combination of properties. It has a high melting point, which allowed it to withstand the extreme temperatures generated by the aircraft's skin friction. Additionally, quartz is highly transparent, allowing for unobstructed views of the surroundings. Its low thermal expansion coefficient also ensured that the windows would not distort or crack due to temperature changes.

2. Manufacturing Process

The manufacturing process for the SR-71's quartz windows was highly complex and involved several stages. The first step was to create a molten pool of quartz, which was then floated onto a bath of molten tin. This process, known as the "float glass" method, allowed the quartz to spread evenly and form a flat, smooth surface. The quartz was then annealed, or heat-treated, to relieve any stresses that may have developed during the manufacturing process.

The Challenge of Working with Quartz

Working with quartz posed several challenges, including its high melting point and tendency to fracture or shatter. To overcome these challenges, the manufacturers developed specialized tools and techniques, such as using a high-temperature furnace to melt the quartz and a precision cutting machine to shape the windows.

3. Optical Quality

The SR-71's quartz windows were designed to provide exceptional optical quality, allowing the aircraft's sensors and cameras to gather high-resolution images of the surrounding environment. The windows were made with a high degree of flatness and surface finish, ensuring that the images captured by the sensors were sharp and clear.

Meeting the Requirements of High-Speed Flight

The SR-71's quartz windows had to meet extremely stringent requirements, including withstanding the intense pressure and heat generated by high-speed flight. The windows were also designed to be resistant to optical distortion, ensuring that the images captured by the sensors were accurate and reliable.

4. Contribution to the SR-71's Success

The SR-71's quartz windows played a crucial role in the aircraft's success, allowing it to gather intelligence at high speeds and altitudes. The windows provided a clear view of the surrounding environment, enabling the aircraft's sensors and cameras to capture high-resolution images of enemy territory.

Aircraft Performance

The SR-71's quartz windows contributed to the aircraft's exceptional performance, allowing it to fly at speeds over Mach 3.5 (around 2,200 mph or 3,540 km/h) and altitudes above 80,000 feet (24,400 meters). The aircraft's ability to gather intelligence at these extreme conditions made it an invaluable asset for military operations.

5. Weight Reduction

The SR-71's quartz windows were designed to be extremely thin and lightweight, reducing the overall weight of the aircraft. This weight reduction contributed to the aircraft's exceptional performance, allowing it to fly faster and farther than other reconnaissance planes.

Importance of Weight Reduction

Weight reduction was a critical factor in the design of the SR-71, as it allowed the aircraft to achieve its exceptional performance. The use of lightweight materials, such as quartz, helped to reduce the aircraft's overall weight, making it more efficient and effective.

6. Durability

The SR-71's quartz windows were designed to be highly durable, withstanding the intense pressure and heat generated by high-speed flight. The windows were also resistant to optical distortion, ensuring that the images captured by the sensors were accurate and reliable.

Withstanding Extreme Conditions

The SR-71's quartz windows were capable of withstanding extreme conditions, including temperatures above 2,000°F (1,093°C) and pressures exceeding 100 Gs. This durability was essential for the aircraft's success, allowing it to gather intelligence in the most challenging environments.

7. Legacy

The SR-71's quartz windows have left a lasting legacy in the field of aerospace engineering, inspiring the development of new materials and technologies. The aircraft's use of quartz windows demonstrated the potential of advanced materials in high-performance applications.

Influence on Future Aircraft

The SR-71's quartz windows have influenced the design of future aircraft, including the development of advanced sensors and camera systems. The use of quartz windows in the SR-71 has also inspired research into new materials and technologies, driving innovation in the field of aerospace engineering.

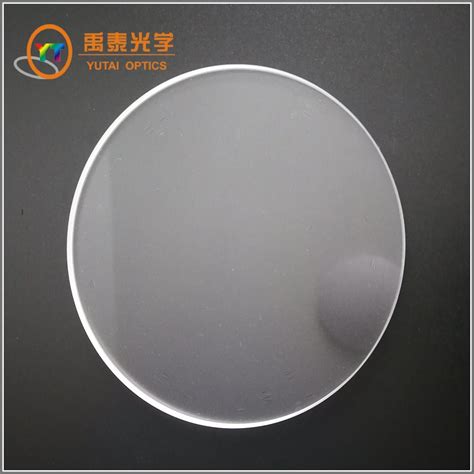

SR-71 Quartz Windows Image Gallery

In conclusion, the SR-71's quartz windows were a crucial component of the aircraft's success, providing exceptional optical quality, durability, and weight reduction. The use of quartz windows in the SR-71 has left a lasting legacy in the field of aerospace engineering, inspiring the development of new materials and technologies. We hope you have enjoyed this article and will share your thoughts on the SR-71's quartz windows in the comments below.