Intro

Temperature mapping is a crucial process in various industries, including pharmaceutical, food, and medical, where temperature-sensitive products are stored, transported, or used. It involves identifying and documenting the temperature distribution within a specific area, such as a warehouse, storage room, or vehicle. Temperature mapping protocols are essential to ensure that products are stored and transported within a safe temperature range, maintaining their quality and integrity. In this article, we will outline the 7 essential steps for a temperature mapping protocol.

Understanding the Importance of Temperature Mapping

Temperature mapping is a critical process that helps to identify temperature variations within a specific area. It is essential to ensure that products are stored and transported within a safe temperature range, which is critical for maintaining their quality and integrity. Temperature mapping protocols help to detect any temperature fluctuations, which can be detrimental to the products.

Step 1: Define the Scope and Objectives

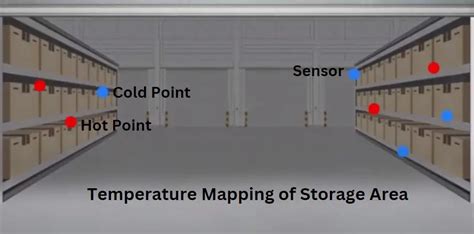

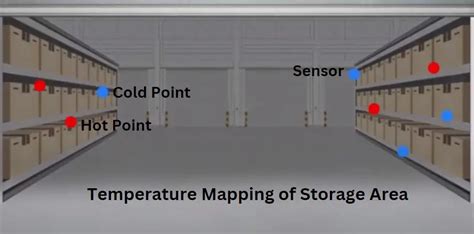

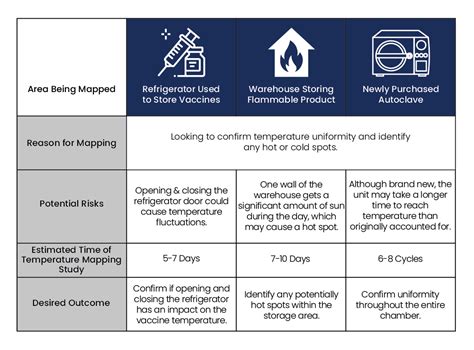

The first step in creating a temperature mapping protocol is to define the scope and objectives of the mapping exercise. This includes identifying the area to be mapped, the type of products stored or transported, and the temperature range required for the products. The objectives of the mapping exercise should be clearly defined, including the identification of temperature variations, the detection of hot and cold spots, and the development of a corrective action plan.

Step 2: Gather Equipment and Resources

The second step is to gather the necessary equipment and resources required for the temperature mapping exercise. This includes temperature data loggers, thermocouples, and other measurement devices. The equipment should be calibrated and validated to ensure accuracy and precision.

Step 3: Develop a Mapping Strategy

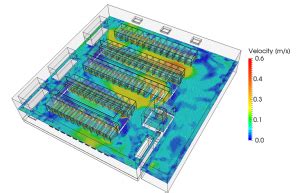

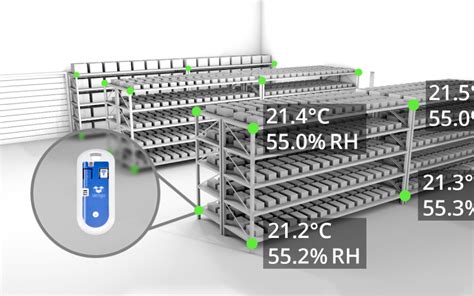

The third step is to develop a mapping strategy, which includes identifying the locations where temperature measurements will be taken. The strategy should take into account the size and layout of the area, the type of products stored or transported, and the temperature range required for the products. The mapping strategy should also include the frequency of measurements, the duration of the mapping exercise, and the data analysis procedure.

Step 4: Conduct the Temperature Mapping Exercise

The fourth step is to conduct the temperature mapping exercise, which involves taking temperature measurements at the designated locations. The measurements should be taken over a specified period, and the data should be recorded and analyzed.

Step 5: Analyze the Data

The fifth step is to analyze the data collected during the temperature mapping exercise. The data should be analyzed to identify temperature variations, hot and cold spots, and any areas where the temperature range is outside the required limits. The data analysis should also include the development of a corrective action plan to address any temperature-related issues.

Step 6: Develop a Corrective Action Plan

The sixth step is to develop a corrective action plan to address any temperature-related issues identified during the data analysis. The plan should include actions to be taken to correct any temperature variations, hot and cold spots, and areas where the temperature range is outside the required limits.

Step 7: Review and Update the Protocol

The seventh and final step is to review and update the temperature mapping protocol regularly. The protocol should be reviewed to ensure that it is effective in identifying temperature variations and addressing any temperature-related issues. The protocol should also be updated to reflect any changes in the area, products, or temperature range required.

Temperature Mapping Protocol Gallery

Temperature Mapping Protocol Image Gallery

In conclusion, a temperature mapping protocol is an essential tool for ensuring that products are stored and transported within a safe temperature range. By following the 7 essential steps outlined in this article, you can develop a comprehensive temperature mapping protocol that helps to maintain the quality and integrity of your products.