Discover the crucial role of welding in the military and the specialized skills required for success. Learn about the various welding techniques and technologies used in military applications, from equipment repair to infrastructure development, and the benefits of military welding training for civilian careers, including MIG, TIG, and arc welding.

Welding is a critical skill set that plays a vital role in various industries, including the military. In the military, welding is used for a wide range of applications, from repairing and maintaining equipment to fabricating new components and structures. Military personnel who possess welding skills are in high demand, as they are essential for ensuring the readiness and effectiveness of military equipment and operations.

The military relies heavily on welding for various reasons. Firstly, welding is a cost-effective way to repair and maintain equipment, which is essential for reducing maintenance costs and extending the lifespan of military assets. Secondly, welding allows for the fabrication of custom components and structures that are not readily available or are too expensive to procure. Finally, welding is a critical skill set for military personnel who are deployed in remote or austere environments, where access to repair facilities and spare parts may be limited.

The importance of welding in the military cannot be overstated. In combat situations, the ability to weld can mean the difference between life and death. For example, welding can be used to repair damaged equipment, such as tanks and aircraft, which can quickly get back into operation. Additionally, welding can be used to fabricate makeshift repairs, such as repairing damaged tracks or creating improvised armor plating.

Types of Welding Used in the Military

The military uses various types of welding, including:

Shielded Metal Arc Welding (SMAW)

SMAW, also known as "stick" welding, is a common welding process used in the military. It involves using a consumable electrode covered in a flux to protect the arc and molten metal from the atmosphere. SMAW is widely used for repairing and maintaining equipment, as well as for fabricating new components and structures.

Gas Metal Arc Welding (GMAW)

GMAW, also known as "MIG" welding, is another common welding process used in the military. It involves using a continuous wire electrode and an inert gas to shield the arc and molten metal. GMAW is widely used for welding thin-gauge metals, such as aluminum and steel.

Gas Tungsten Arc Welding (GTAW)

GTAW, also known as "TIG" welding, is a precision welding process used in the military. It involves using a non-consumable tungsten electrode and an inert gas to shield the arc and molten metal. GTAW is widely used for welding critical components, such as aircraft and missile parts.

Military Welding Equipment and Tools

The military uses a wide range of welding equipment and tools, including:

Welding Machines

Welding machines are used to generate the electrical arc needed for welding. The military uses a variety of welding machines, including SMAW, GMAW, and GTAW machines.

Welding Electrodes

Welding electrodes are used to transfer the electrical arc to the workpiece. The military uses a variety of welding electrodes, including SMAW, GMAW, and GTAW electrodes.

Welding Helmets and Shields

Welding helmets and shields are used to protect the welder's face and eyes from the intense light and heat generated by the welding arc. The military uses a variety of welding helmets and shields, including automatic darkening helmets and fixed-shade helmets.

Military Welding Safety Precautions

Welding can be a hazardous activity, and the military takes welding safety precautions seriously. Some of the safety precautions used by the military include:

Personal Protective Equipment (PPE)

PPE, such as welding helmets, gloves, and safety glasses, is used to protect the welder's face, eyes, and skin from the intense light and heat generated by the welding arc.

Ventilation

Ventilation is used to remove welding fumes and particles from the air. The military uses a variety of ventilation systems, including exhaust fans and respirators.

Fire Prevention

Fire prevention measures are used to prevent fires from starting. The military uses a variety of fire prevention measures, including fire extinguishers and fire-resistant materials.

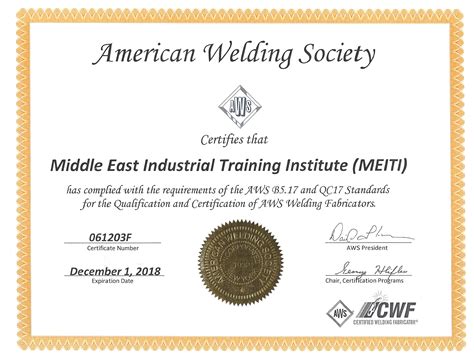

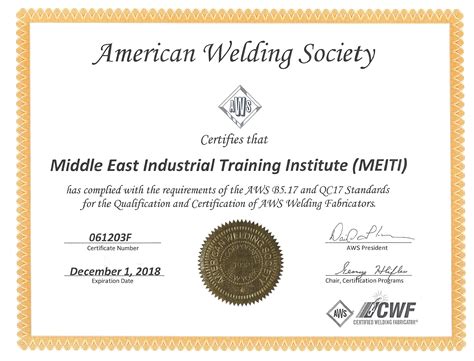

Military Welding Training and Certification

The military provides extensive training and certification programs for welders. Military welders must complete a rigorous training program, which includes both classroom and hands-on training. Upon completion of the training program, military welders are certified in one or more welding processes.

Welding Certifications

The military offers a variety of welding certifications, including SMAW, GMAW, and GTAW certifications. Military welders must pass a written and practical exam to become certified.

Welding Qualifications

The military also offers welding qualifications, which are used to qualify welders to work on specific equipment and projects. Military welders must meet specific qualification requirements, which include passing a written and practical exam.

Gallery of Military Welding Images

Military Welding Image Gallery

We hope this article has provided you with a comprehensive understanding of the critical role that welding plays in the military. Whether you're a military personnel or a civilian, welding is an essential skill set that can benefit you in many ways. If you have any questions or would like to learn more about military welding, please don't hesitate to contact us.