Intro

Boost productivity and reduce waste with expert strategies from industrial engineers. Discover 5 ways they improve efficiency, from optimizing workflows and supply chains to implementing lean manufacturing and automation. Learn how to streamline processes, reduce costs, and enhance quality with the latest industrial engineering techniques and tools.

Industrial engineers play a crucial role in optimizing the efficiency of various industries, from manufacturing to healthcare. By analyzing systems, identifying bottlenecks, and implementing improvements, industrial engineers help organizations streamline their operations, reduce waste, and increase productivity. In this article, we will explore five ways industrial engineers improve efficiency in different sectors.

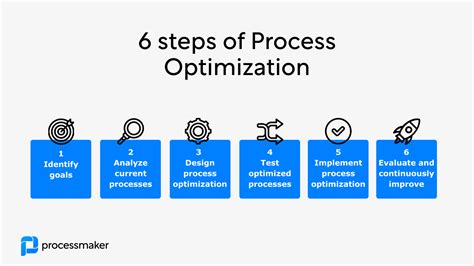

1. Process Optimization

One of the primary ways industrial engineers improve efficiency is by optimizing processes. This involves analyzing the workflow, identifying areas of inefficiency, and implementing changes to improve productivity. By streamlining processes, industrial engineers can help organizations reduce waste, decrease lead times, and increase overall efficiency.

For example, in a manufacturing plant, an industrial engineer might analyze the production line and identify bottlenecks that are slowing down production. By implementing changes such as rearranging the layout, improving communication between workers, or introducing new technology, the engineer can help increase production rates and reduce waste.

Benefits of Process Optimization

- Improved productivity

- Reduced waste

- Decreased lead times

- Increased efficiency

2. Lean Manufacturing

Lean manufacturing is a philosophy that aims to minimize waste and maximize value-added activities. Industrial engineers play a key role in implementing lean manufacturing principles, which involve identifying and eliminating non-value-added activities, improving workflow, and increasing efficiency.

For instance, in a hospital setting, an industrial engineer might apply lean principles to improve patient flow. By analyzing the workflow, identifying bottlenecks, and implementing changes such as streamlining patient registration or improving communication between staff, the engineer can help reduce waiting times, improve patient satisfaction, and increase efficiency.

Benefits of Lean Manufacturing

- Reduced waste

- Improved productivity

- Increased efficiency

- Enhanced patient satisfaction

3. Quality Control

Industrial engineers also play a crucial role in ensuring quality control. By analyzing data, identifying trends, and implementing improvements, engineers can help organizations reduce defects, improve product quality, and increase customer satisfaction.

For example, in a food processing plant, an industrial engineer might analyze data on product defects and identify areas for improvement. By implementing changes such as improving quality control measures, training staff, or introducing new technology, the engineer can help reduce defects, improve product quality, and increase customer satisfaction.

Benefits of Quality Control

- Reduced defects

- Improved product quality

- Increased customer satisfaction

- Enhanced reputation

4. Supply Chain Optimization

Supply chain optimization is another key area where industrial engineers can improve efficiency. By analyzing the supply chain, identifying bottlenecks, and implementing improvements, engineers can help organizations reduce lead times, decrease costs, and increase efficiency.

For instance, in a retail setting, an industrial engineer might analyze the supply chain and identify areas for improvement. By implementing changes such as improving inventory management, streamlining logistics, or introducing new technology, the engineer can help reduce lead times, decrease costs, and increase efficiency.

Benefits of Supply Chain Optimization

- Reduced lead times

- Decreased costs

- Increased efficiency

- Improved customer satisfaction

5. Workforce Optimization

Finally, industrial engineers can improve efficiency by optimizing the workforce. By analyzing workforce data, identifying trends, and implementing improvements, engineers can help organizations reduce labor costs, improve productivity, and increase efficiency.

For example, in a manufacturing setting, an industrial engineer might analyze workforce data and identify areas for improvement. By implementing changes such as improving training programs, introducing new technology, or optimizing workflows, the engineer can help reduce labor costs, improve productivity, and increase efficiency.

Benefits of Workforce Optimization

- Reduced labor costs

- Improved productivity

- Increased efficiency

- Enhanced job satisfaction

Industrial Engineers Improving Efficiency Image Gallery

In conclusion, industrial engineers play a vital role in improving efficiency in various industries. By optimizing processes, implementing lean manufacturing principles, ensuring quality control, optimizing supply chains, and optimizing the workforce, engineers can help organizations reduce waste, improve productivity, and increase efficiency. As technology continues to evolve, the role of industrial engineers will become even more critical in driving innovation and improvement in various sectors.