Discover the crucial roles of aircraft mechanics in ensuring flight safety. Learn about the 5 key tasks of aircraft mechanics, including routine inspections, repairs, and maintenance, as well as troubleshooting and replacement of aircraft components. Understand the importance of aviation maintenance, aircraft repair, and quality control in the aerospace industry.

The aviation industry relies heavily on the skills and expertise of aircraft mechanics to ensure the safety and airworthiness of aircraft. These professionals play a critical role in maintaining, inspecting, and repairing aircraft to prevent accidents and ensure smooth flight operations. In this article, we will delve into the 5 key tasks of aircraft mechanics, highlighting their responsibilities and the importance of their work.

Aircraft mechanics, also known as aircraft maintenance technicians, are responsible for performing a range of tasks to ensure that aircraft are in good working condition. Their work involves diagnosing problems, repairing and replacing parts, and conducting regular maintenance checks to prevent malfunctions.

The work of aircraft mechanics is highly regulated, with strict guidelines and standards set by aviation authorities such as the Federal Aviation Administration (FAA). These regulations ensure that aircraft are maintained to the highest standards, minimizing the risk of accidents and ensuring the safety of passengers and crew.

5 Key Tasks of Aircraft Mechanics

The Importance of Maintenance Checks

One of the primary tasks of aircraft mechanics is to perform regular maintenance checks on aircraft. These checks are designed to identify potential problems before they become major issues, ensuring that the aircraft remains airworthy and safe to fly. Maintenance checks involve inspecting the aircraft's systems, including the engine, electrical, and hydraulic systems, as well as checking for any signs of wear and tear.

Aircraft mechanics use a range of tools and equipment to perform maintenance checks, including specialized software and diagnostic equipment. They must also keep detailed records of their work, including any repairs or replacements made to the aircraft.

Types of Maintenance Checks

There are several types of maintenance checks that aircraft mechanics perform, including:

- Routine maintenance checks: These checks are performed on a regular basis, typically every 100-200 hours of flight time.

- Non-routine maintenance checks: These checks are performed in response to a specific issue or problem with the aircraft.

- Pre-flight checks: These checks are performed before each flight to ensure that the aircraft is airworthy.

Task 2: Repairing and Replacing Parts

Repairing and Replacing Parts

Another key task of aircraft mechanics is to repair and replace parts on the aircraft. This involves identifying faulty or damaged parts and replacing them with new or refurbished ones. Aircraft mechanics must have a strong understanding of the aircraft's systems and components, as well as the ability to use specialized tools and equipment.

Repairing and replacing parts is a critical task, as faulty parts can pose a significant safety risk to passengers and crew. Aircraft mechanics must follow strict guidelines and regulations when performing repairs, ensuring that all work is done to the highest standards.

Types of Repairs

Aircraft mechanics perform a range of repairs, including:

- Minor repairs: These repairs involve replacing small parts or making minor adjustments to the aircraft's systems.

- Major repairs: These repairs involve replacing major components or making significant repairs to the aircraft's systems.

- Overhaul repairs: These repairs involve completely overhauling the aircraft's engine or other major components.

Task 3: Inspecting Aircraft Systems

Inspecting Aircraft Systems

Aircraft mechanics are responsible for inspecting the aircraft's systems to ensure that they are functioning properly. This involves using specialized tools and equipment to inspect the aircraft's engines, electrical, and hydraulic systems, as well as checking for any signs of wear and tear.

Inspecting aircraft systems is a critical task, as faulty systems can pose a significant safety risk to passengers and crew. Aircraft mechanics must follow strict guidelines and regulations when performing inspections, ensuring that all work is done to the highest standards.

Types of Inspections

Aircraft mechanics perform a range of inspections, including:

- Routine inspections: These inspections are performed on a regular basis, typically every 100-200 hours of flight time.

- Non-routine inspections: These inspections are performed in response to a specific issue or problem with the aircraft.

- Pre-flight inspections: These inspections are performed before each flight to ensure that the aircraft is airworthy.

Task 4: Troubleshooting

Troubleshooting

Aircraft mechanics are responsible for troubleshooting problems with the aircraft's systems. This involves using specialized tools and equipment to diagnose issues and identify faulty parts or systems.

Troubleshooting is a critical task, as faulty systems can pose a significant safety risk to passengers and crew. Aircraft mechanics must have a strong understanding of the aircraft's systems and components, as well as the ability to use specialized tools and equipment.

Types of Troubleshooting

Aircraft mechanics perform a range of troubleshooting tasks, including:

- Diagnostic troubleshooting: This involves using specialized software and diagnostic equipment to identify issues with the aircraft's systems.

- Visual troubleshooting: This involves visually inspecting the aircraft's systems to identify signs of wear and tear or faulty parts.

Task 5: Keeping Records

Keeping Records

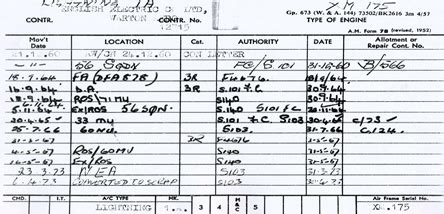

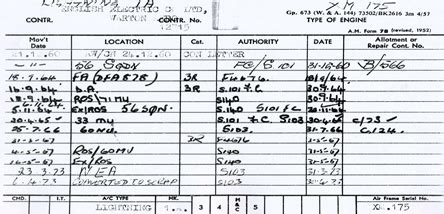

Finally, aircraft mechanics are responsible for keeping detailed records of their work, including any repairs or replacements made to the aircraft. This involves maintaining accurate and detailed records of all maintenance checks, inspections, and repairs performed on the aircraft.

Keeping records is a critical task, as it ensures that the aircraft's maintenance history is accurately documented and easily accessible. This helps to ensure that the aircraft is airworthy and safe to fly.

Types of Records

Aircraft mechanics maintain a range of records, including:

- Maintenance records: These records document all maintenance checks, inspections, and repairs performed on the aircraft.

- Inspection records: These records document all inspections performed on the aircraft, including any issues or problems identified.

- Repair records: These records document all repairs performed on the aircraft, including any parts replaced or repaired.

Gallery of Aircraft Mechanics at Work

Aircraft Mechanics at Work

In conclusion, the work of aircraft mechanics is critical to ensuring the safety and airworthiness of aircraft. Their tasks involve performing regular maintenance checks, repairing and replacing parts, inspecting aircraft systems, troubleshooting problems, and keeping detailed records of their work. By following strict guidelines and regulations, aircraft mechanics play a vital role in preventing accidents and ensuring the smooth operation of flight.