Intro

Unlock the power of Industrial Engineers! Discover the 5 key roles they play in optimizing systems, increasing efficiency, and reducing waste. From process improvement to project management, learn how Industrial Engineers leverage data analysis, operations research, and lean manufacturing to drive innovation and profitability in various industries.

Industrial engineers play a vital role in optimizing the efficiency and productivity of various industries, including manufacturing, healthcare, and logistics. Their expertise in designing, developing, and implementing systems, processes, and products enables organizations to reduce costs, improve quality, and enhance customer satisfaction. In this article, we will delve into the five key roles of industrial engineers and explore their responsibilities, skills, and impact on industries.

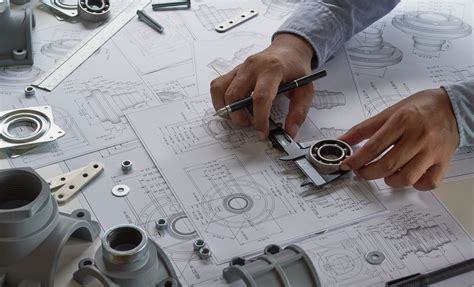

Role 1: Design and Development

Industrial engineers are responsible for designing and developing new systems, processes, and products. They use computer-aided design (CAD) software, simulations, and modeling techniques to create prototypes and test their performance. Their goal is to create efficient, cost-effective, and safe solutions that meet customer requirements and industry standards.

In this role, industrial engineers must possess excellent problem-solving skills, creativity, and attention to detail. They must also be able to communicate effectively with stakeholders, including customers, suppliers, and colleagues.

Key Responsibilities:

- Designing and developing new products, processes, and systems

- Conducting simulations and modeling to test performance

- Collaborating with cross-functional teams to ensure successful implementation

- Ensuring compliance with industry standards and regulations

Role 2: Process Improvement

Industrial engineers are responsible for analyzing and improving existing processes to increase efficiency, reduce costs, and enhance quality. They use techniques such as lean manufacturing, Six Sigma, and total productive maintenance (TPM) to identify and eliminate waste, reduce variability, and improve throughput.

In this role, industrial engineers must possess strong analytical and problem-solving skills, as well as excellent communication and interpersonal skills. They must be able to work with stakeholders to identify opportunities for improvement and implement changes.

Key Responsibilities:

- Analyzing existing processes to identify opportunities for improvement

- Implementing lean manufacturing, Six Sigma, and TPM techniques

- Collaborating with stakeholders to implement changes

- Monitoring and evaluating the effectiveness of process improvements

Role 3: Quality Control and Assurance

Industrial engineers are responsible for ensuring that products and processes meet quality and safety standards. They design and implement quality control systems, conduct audits and inspections, and analyze data to identify trends and opportunities for improvement.

In this role, industrial engineers must possess strong analytical and problem-solving skills, as well as excellent attention to detail. They must be able to communicate effectively with stakeholders and ensure compliance with industry regulations and standards.

Key Responsibilities:

- Designing and implementing quality control systems

- Conducting audits and inspections to ensure compliance

- Analyzing data to identify trends and opportunities for improvement

- Collaborating with stakeholders to implement changes

Role 4: Supply Chain Management

Industrial engineers are responsible for managing supply chains to ensure that products are delivered on time, at the right cost, and with the required quality. They analyze data, optimize inventory levels, and develop logistics strategies to reduce costs and improve efficiency.

In this role, industrial engineers must possess strong analytical and problem-solving skills, as well as excellent communication and interpersonal skills. They must be able to work with stakeholders to identify opportunities for improvement and implement changes.

Key Responsibilities:

- Analyzing data to optimize inventory levels and logistics strategies

- Collaborating with stakeholders to implement changes

- Monitoring and evaluating the effectiveness of supply chain management strategies

- Ensuring compliance with industry regulations and standards

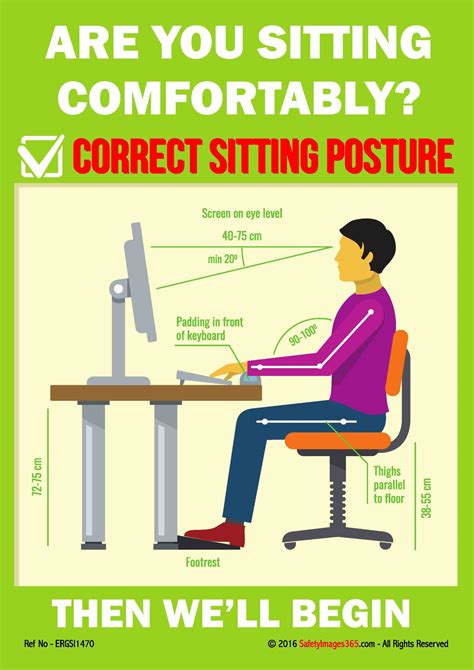

Role 5: Ergonomics and Safety

Industrial engineers are responsible for designing and implementing ergonomic and safe workspaces to reduce the risk of injury and improve employee well-being. They analyze data, conduct risk assessments, and develop strategies to reduce musculoskeletal disorders, noise exposure, and other workplace hazards.

In this role, industrial engineers must possess strong analytical and problem-solving skills, as well as excellent communication and interpersonal skills. They must be able to work with stakeholders to identify opportunities for improvement and implement changes.

Key Responsibilities:

- Analyzing data to identify opportunities for ergonomic and safety improvements

- Conducting risk assessments to identify potential hazards

- Developing strategies to reduce musculoskeletal disorders, noise exposure, and other workplace hazards

- Collaborating with stakeholders to implement changes

Industrial Engineers at Work Image Gallery

In conclusion, industrial engineers play a critical role in ensuring the efficiency, productivity, and quality of various industries. Their expertise in design, development, process improvement, quality control, supply chain management, and ergonomics and safety enables organizations to reduce costs, improve customer satisfaction, and enhance competitiveness. If you're interested in learning more about the roles and responsibilities of industrial engineers, we encourage you to share your thoughts and questions in the comments section below.