Intro

Discover the 5 key roles of an industrial engineer, from optimizing manufacturing processes to improving quality control and supply chain management. Learn how industrial engineers apply lean principles, use data analytics, and implement sustainable solutions to drive efficiency and innovation in various industries.

Industrial engineers play a vital role in optimizing the efficiency and productivity of systems, processes, and organizations. They are responsible for designing, implementing, and improving integrated systems that involve people, materials, equipment, and energy. In this article, we will explore the five key roles of an industrial engineer and how they contribute to the success of various industries.

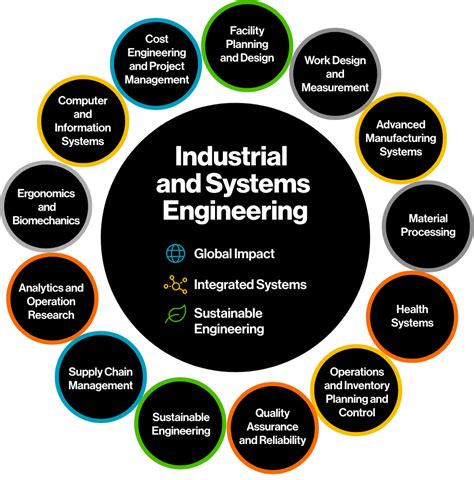

What is Industrial Engineering?

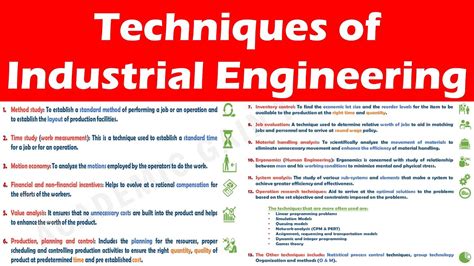

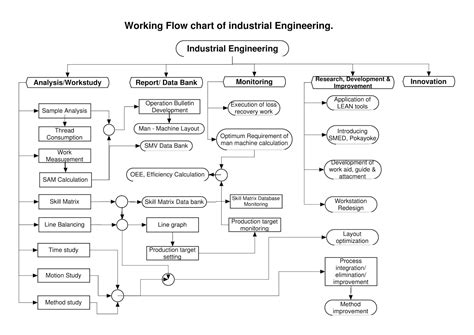

Industrial engineering is a branch of engineering that deals with the design, improvement, and installation of integrated systems of people, materials, equipment, and energy. It involves analyzing and optimizing the use of resources, eliminating waste, and improving productivity. Industrial engineers use a combination of technical knowledge, business acumen, and social skills to achieve these goals.

Role 1: Process Improvement

One of the primary roles of an industrial engineer is to identify areas for process improvement and implement changes to increase efficiency and productivity. This involves analyzing data, identifying bottlenecks, and developing solutions to optimize workflows. Industrial engineers use various tools and techniques, such as lean manufacturing, Six Sigma, and total quality management, to improve processes and reduce waste.

Key Responsibilities:

- Analyze data to identify areas for process improvement

- Develop and implement process changes to increase efficiency and productivity

- Collaborate with cross-functional teams to implement changes

- Monitor and evaluate the effectiveness of process improvements

Role 2: System Design

Industrial engineers are responsible for designing and developing integrated systems that involve people, materials, equipment, and energy. This includes designing production systems, supply chains, and logistics systems. Industrial engineers use computer-aided design (CAD) software and other tools to create models and simulations of systems.

Key Responsibilities:

- Design and develop integrated systems that meet customer requirements

- Use CAD software and other tools to create models and simulations of systems

- Collaborate with cross-functional teams to ensure system design meets requirements

- Test and evaluate system design to ensure effectiveness

Role 3: Operations Research

Industrial engineers use operations research techniques to analyze and optimize complex systems. This involves using mathematical models and algorithms to analyze data and make informed decisions. Industrial engineers use operations research to optimize supply chains, production planning, and inventory management.

Key Responsibilities:

- Use mathematical models and algorithms to analyze data and make informed decisions

- Develop and implement optimization models to improve system performance

- Collaborate with cross-functional teams to implement changes

- Monitor and evaluate the effectiveness of optimization models

Role 4: Quality Control

Industrial engineers are responsible for ensuring that products and services meet customer requirements and industry standards. This involves developing and implementing quality control processes, such as inspection and testing, to ensure that products meet specifications. Industrial engineers also use statistical process control (SPC) and other techniques to monitor and control process variation.

Key Responsibilities:

- Develop and implement quality control processes to ensure products meet specifications

- Use SPC and other techniques to monitor and control process variation

- Collaborate with cross-functional teams to implement quality control processes

- Monitor and evaluate the effectiveness of quality control processes

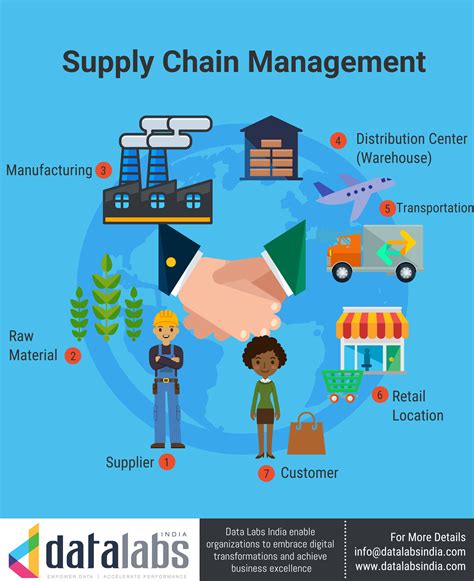

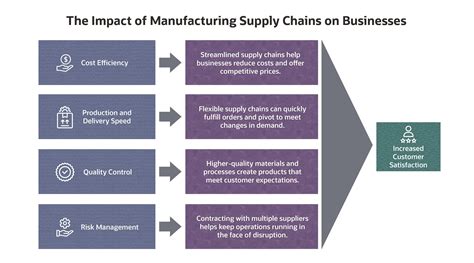

Role 5: Supply Chain Management

Industrial engineers are responsible for managing supply chains to ensure that products are delivered to customers on time and at the right cost. This involves developing and implementing supply chain strategies, such as just-in-time (JIT) and vendor-managed inventory (VMI), to optimize supply chain performance. Industrial engineers also use data analytics and other tools to monitor and evaluate supply chain performance.

Key Responsibilities:

- Develop and implement supply chain strategies to optimize supply chain performance

- Use data analytics and other tools to monitor and evaluate supply chain performance

- Collaborate with cross-functional teams to implement supply chain changes

- Monitor and evaluate the effectiveness of supply chain strategies

Industrial Engineering Image Gallery

We hope this article has provided you with a comprehensive understanding of the key roles of an industrial engineer. From process improvement to supply chain management, industrial engineers play a vital role in optimizing the efficiency and productivity of systems, processes, and organizations. If you have any questions or comments, please feel free to share them below.