Intro

Discover the power of thrust vectoring, a game-changing technology that enables aircraft to fly with unparalleled agility and precision. Learn how it works, its benefits, and applications in aerospace engineering. Get a simple explanation of thrust vectoring, including its types, advantages, and real-world examples, and explore its role in shaping the future of flight.

Thrust vectoring is a complex concept in aerospace engineering that plays a crucial role in the development of advanced aircraft and spacecraft. In simple terms, thrust vectoring refers to the ability of an aircraft or spacecraft to change the direction of its thrust, or the force that propels it forward. This technology has revolutionized the way aircraft and spacecraft maneuver, making them more agile and efficient.

In traditional aircraft, the thrust is fixed in one direction, which means that the plane can only move in a straight line. However, with thrust vectoring, the aircraft can change the direction of its thrust, allowing it to turn, climb, and descend more easily. This technology has been used in various military aircraft, including fighter jets and bombers, as well as in some commercial aircraft.

The concept of thrust vectoring is not new, and it has been around for several decades. However, recent advancements in materials and design have made it possible to develop more efficient and reliable thrust vectoring systems. These systems use a combination of mechanical and electrical components to control the direction of the thrust, allowing the aircraft to maneuver more precisely.

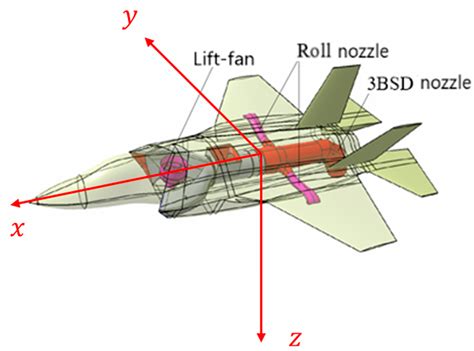

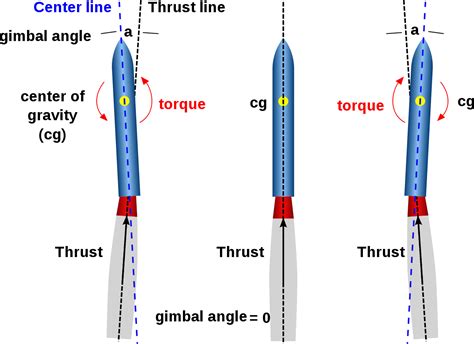

How Thrust Vectoring Works

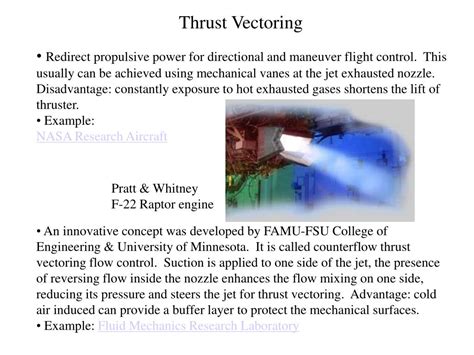

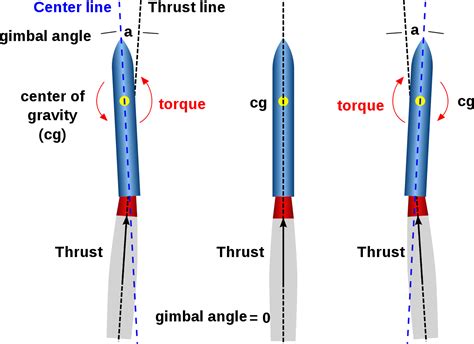

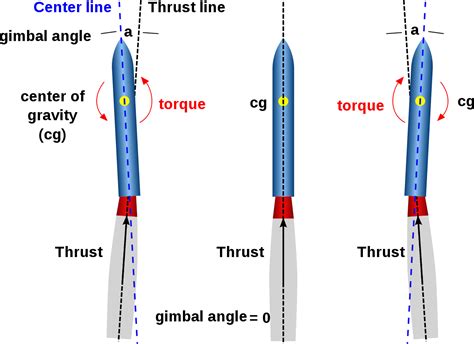

Thrust vectoring works by using a combination of mechanical and electrical components to control the direction of the thrust. The system typically consists of a nozzle, a control system, and a actuator. The nozzle is the part of the engine that produces the thrust, while the control system is the brain of the operation, determining the direction of the thrust. The actuator is the component that actually changes the direction of the nozzle.

When the control system sends a signal to the actuator, it adjusts the nozzle to change the direction of the thrust. This allows the aircraft to turn, climb, or descend more easily. The system can also be used to control the speed of the aircraft, making it more efficient and agile.

Types of Thrust Vectoring

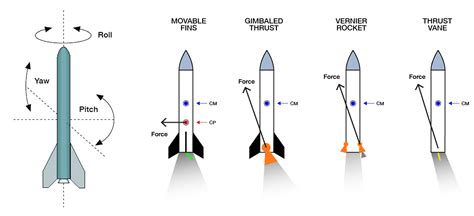

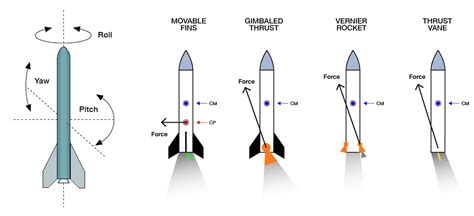

There are several types of thrust vectoring systems, including:

- Mechanical Thrust Vectoring: This type of system uses mechanical components, such as gears and levers, to control the direction of the thrust.

- Electrical Thrust Vectoring: This type of system uses electrical components, such as motors and actuators, to control the direction of the thrust.

- Hydraulic Thrust Vectoring: This type of system uses hydraulic components, such as pumps and cylinders, to control the direction of the thrust.

Each type of thrust vectoring system has its own advantages and disadvantages, and the choice of system depends on the specific application and requirements of the aircraft.

Benefits of Thrust Vectoring

Thrust vectoring offers several benefits, including:

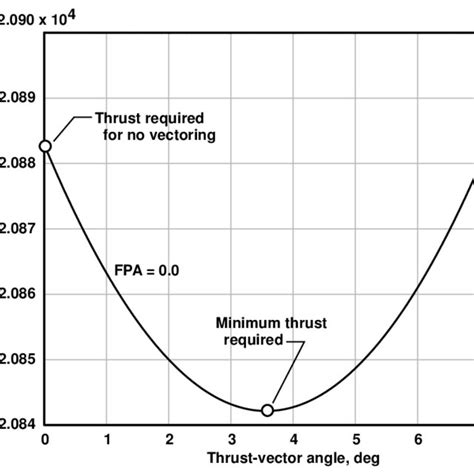

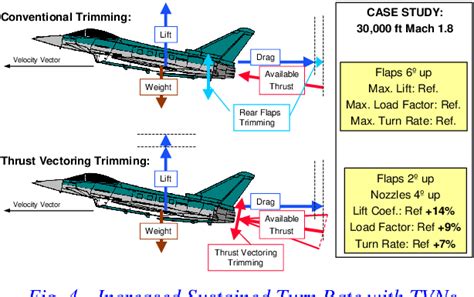

- Improved Maneuverability: Thrust vectoring allows aircraft to turn and climb more easily, making them more agile and efficient.

- Increased Safety: Thrust vectoring can improve safety by allowing aircraft to avoid obstacles and hazards more easily.

- Reduced Fuel Consumption: Thrust vectoring can reduce fuel consumption by allowing aircraft to fly more efficiently.

- Increased Payload Capacity: Thrust vectoring can increase payload capacity by allowing aircraft to carry more weight.

Applications of Thrust Vectoring

Thrust vectoring has a wide range of applications, including:

- Military Aircraft: Thrust vectoring is used in many military aircraft, including fighter jets and bombers.

- Commercial Aircraft: Thrust vectoring is used in some commercial aircraft, including business jets and regional airliners.

- Spacecraft: Thrust vectoring is used in some spacecraft, including satellites and space probes.

- Missiles: Thrust vectoring is used in some missiles, including ballistic missiles and cruise missiles.

Challenges of Thrust Vectoring

Thrust vectoring also has several challenges, including:

- Complexity: Thrust vectoring systems are complex and require sophisticated control systems.

- Weight: Thrust vectoring systems can add weight to the aircraft, which can reduce its performance.

- Cost: Thrust vectoring systems can be expensive to develop and maintain.

Despite these challenges, thrust vectoring remains an important technology in aerospace engineering, and it continues to play a crucial role in the development of advanced aircraft and spacecraft.

Future of Thrust Vectoring

The future of thrust vectoring looks bright, with several new technologies and applications on the horizon. Some of the future developments in thrust vectoring include:

- Electric Thrust Vectoring: Electric thrust vectoring systems use electric motors and actuators to control the direction of the thrust.

- Artificial Intelligence: Artificial intelligence can be used to improve the control and efficiency of thrust vectoring systems.

- Advanced Materials: Advanced materials, such as composites and nanomaterials, can be used to reduce the weight and increase the performance of thrust vectoring systems.

Gallery of Thrust Vectoring

Thrust Vectoring Image Gallery

If you have any questions or comments about thrust vectoring, please leave a comment below. We would be happy to hear from you and provide more information on this topic.