Intro

Ensure a safe welder work environment with these 7 essential tips. Learn how to prevent welding hazards, improve ventilation, and reduce fire risks. Discover the importance of personal protective equipment (PPE), proper storage, and emergency preparedness. Create a safe and healthy workspace for welders with these expert guidelines.

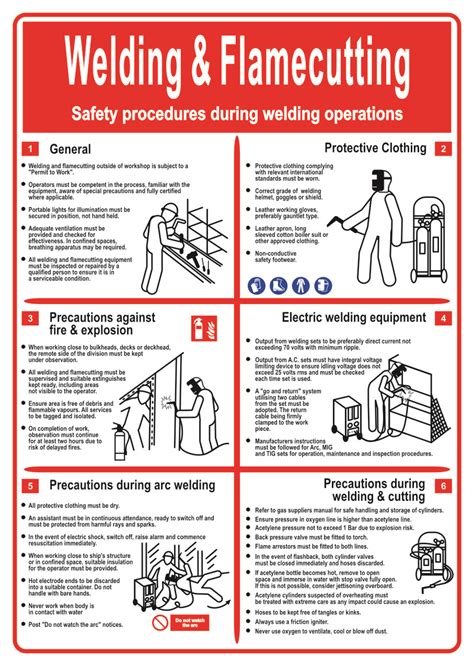

Welding is a crucial process in various industries, including construction, manufacturing, and repair. However, it can be hazardous if proper safety measures are not taken. A safe welder work environment is essential to prevent injuries, ensure the quality of work, and boost productivity. In this article, we will discuss seven tips to create a safe welder work environment.

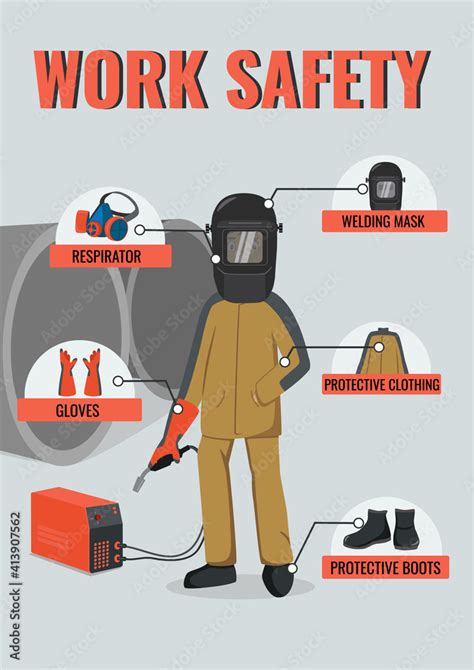

Tip 1: Personal Protective Equipment (PPE)

Personal protective equipment (PPE) is the most critical aspect of a safe welder work environment. Welders should wear PPE to protect themselves from the hazards associated with welding, such as heat, sparks, and fumes. The essential PPE for welders includes:

- A welding helmet or shield to protect the face and eyes from sparks and UV radiation

- Safety glasses or goggles to protect the eyes from debris and chemical splashes

- A fire-resistant welding jacket and pants to prevent burns from sparks and flames

- Insulated, fire-resistant gloves to prevent electrical shock and burns

- Steel-toed boots or shoes to prevent foot injuries from heavy objects

Choosing the Right PPE

When choosing PPE, consider the type of welding you will be doing, the materials you will be working with, and the level of risk involved. For example, if you will be working with hazardous materials, you may need to wear a respirator or a hazmat suit.

Tip 2: Ventilation and Fume Extraction

Proper ventilation and fume extraction are crucial in a welder work environment to prevent inhalation of hazardous fumes and particles. Welding fumes can contain toxic substances like lead, cadmium, and chromium, which can cause respiratory problems and other health issues.

- Use a fume extraction system or a ventilation system to remove fumes and particles from the air

- Ensure good airflow in the work area to prevent the accumulation of fumes

- Use a respirator or a mask if you are working in a confined space or with hazardous materials

Types of Ventilation Systems

There are different types of ventilation systems available, including:

- Local exhaust ventilation (LEV) systems, which capture fumes at the source

- General ventilation systems, which provide overall airflow in the work area

- Portable ventilation systems, which can be moved around the work area as needed

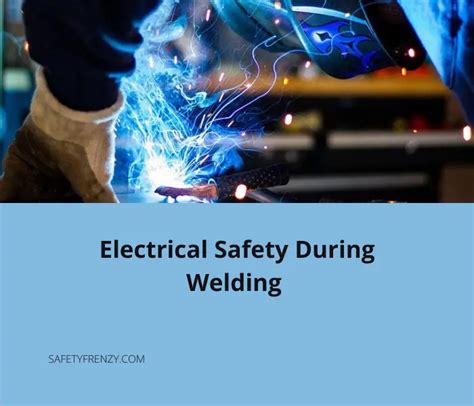

Tip 3: Electrical Safety

Electrical safety is critical in a welder work environment to prevent electrical shock, arc flash, and other electrical hazards.

- Use electrical equipment and tools that are designed for welding and meet safety standards

- Ensure that all electrical equipment is properly installed, maintained, and inspected

- Use personal protective equipment, such as insulated gloves and safety glasses, when working with electrical equipment

Electrical Safety Precautions

When working with electrical equipment, take the following precautions:

- Turn off the power source when not in use

- Use lockout/tagout procedures to prevent accidental start-up

- Keep electrical equipment away from water and moisture

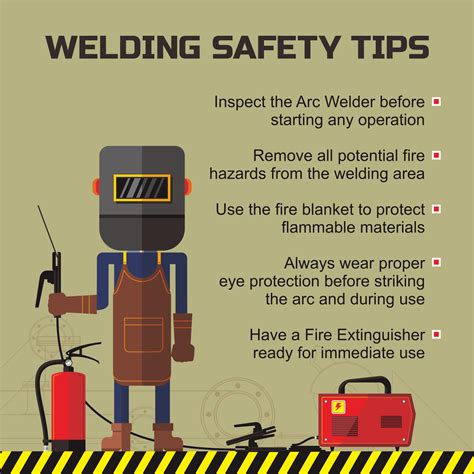

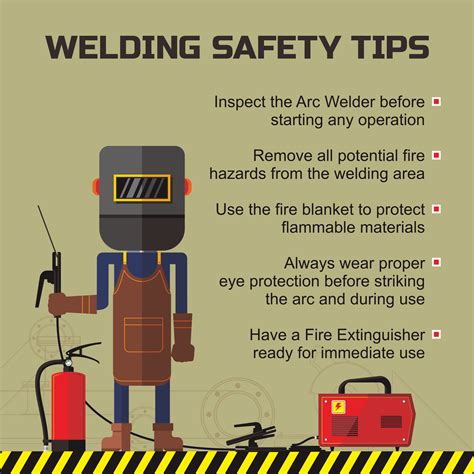

Tip 4: Fire Safety

Fire safety is essential in a welder work environment to prevent fires and ensure a quick response in case of an emergency.

- Keep a fire extinguisher in the work area and ensure that it is easily accessible

- Use fire-resistant materials and equipment in the work area

- Keep the work area clean and free of combustible materials

Types of Fire Extinguishers

There are different types of fire extinguishers available, including:

- Class A extinguishers, which are designed for ordinary combustibles like paper and wood

- Class B extinguishers, which are designed for flammable liquids and gases

- Class C extinguishers, which are designed for electrical fires

Tip 5: Ergonomics and Comfort

Ergonomics and comfort are important in a welder work environment to prevent musculoskeletal disorders and other health issues.

- Use an ergonomic welding station or chair to reduce strain and discomfort

- Keep the work area clean and organized to reduce tripping hazards and improve visibility

- Take regular breaks to stretch and rest

Benefits of Ergonomics

Ergonomics can provide several benefits, including:

- Reduced risk of musculoskeletal disorders

- Improved productivity and efficiency

- Enhanced comfort and well-being

Tip 6: Regular Maintenance and Inspection

Regular maintenance and inspection are crucial in a welder work environment to ensure that equipment is in good working condition and to prevent accidents.

- Regularly inspect and maintain welding equipment, including cables, hoses, and nozzles

- Check for wear and tear, damage, or malfunction

- Follow the manufacturer's instructions for maintenance and repair

Types of Maintenance

There are different types of maintenance, including:

- Routine maintenance, which involves regular checks and repairs

- Preventive maintenance, which involves proactive measures to prevent equipment failure

- Corrective maintenance, which involves repairing or replacing faulty equipment

Tip 7: Training and Supervision

Training and supervision are essential in a welder work environment to ensure that welders have the necessary skills and knowledge to work safely and efficiently.

- Provide regular training and supervision to welders, including new hires and experienced workers

- Ensure that welders are familiar with safety procedures and protocols

- Monitor welders' work and provide feedback and coaching as needed

Benefits of Training and Supervision

Training and supervision can provide several benefits, including:

- Improved safety and reduced risk of accidents

- Enhanced productivity and efficiency

- Increased confidence and competence among welders

Welder Safety Image Gallery

By following these seven tips, you can create a safe welder work environment that protects your workers, equipment, and facility. Remember to always prioritize safety and take proactive measures to prevent accidents and injuries.