Effective machine maintenance is crucial for industries that rely heavily on equipment to ensure smooth operations, reduce downtime, and increase overall productivity. One of the most accessible and widely used tools for optimizing machine maintenance is Microsoft Excel. By utilizing an Excel template, maintenance teams can streamline their processes, improve efficiency, and make data-driven decisions.

Benefits of Using Excel Template for Machine Maintenance

Using an Excel template for machine maintenance offers several benefits, including:

- Improved organization: Excel templates help maintenance teams to organize and structure their data in a clear and concise manner.

- Enhanced collaboration: Multiple team members can access and update the template, ensuring that everyone is on the same page.

- Increased efficiency: Pre-built templates save time and reduce the effort required to create maintenance schedules, track inventory, and analyze data.

- Better decision-making: Excel templates enable teams to analyze data, identify trends, and make informed decisions about machine maintenance.

7 Ways to Optimize Machine Maintenance with Excel Template

Here are seven ways to optimize machine maintenance using an Excel template:

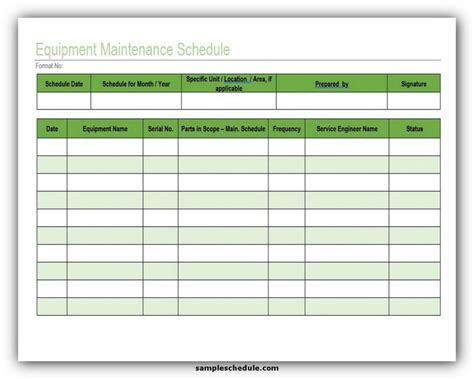

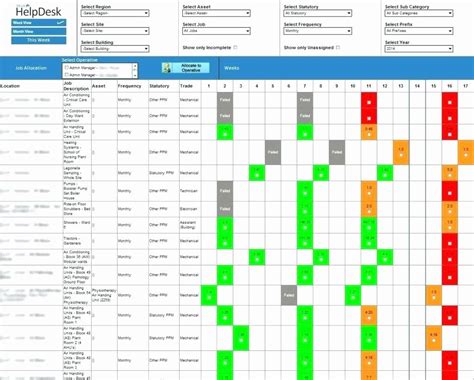

1. Create a Preventive Maintenance Schedule

Use an Excel template to create a preventive maintenance schedule that outlines the frequency and type of maintenance required for each machine. This can include daily, weekly, monthly, and annual maintenance tasks.

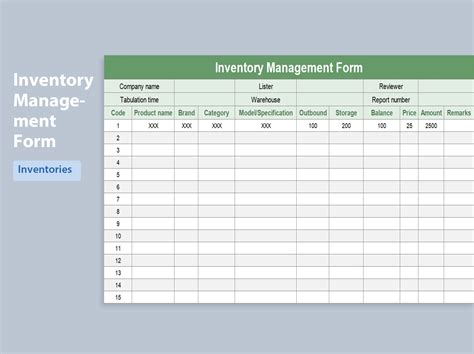

2. Track Inventory and Spare Parts

Set up an Excel template to track inventory and spare parts for each machine. This can include information such as part numbers, quantities, and storage locations.

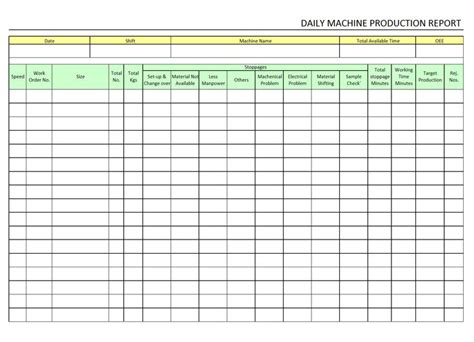

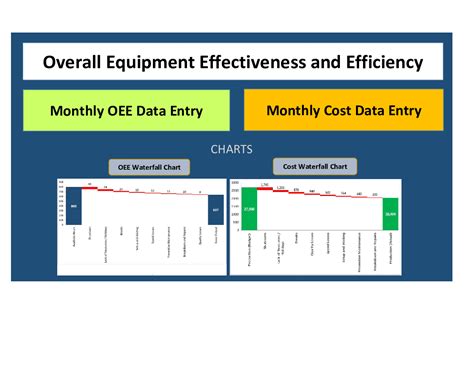

3. Monitor Machine Performance

Use an Excel template to monitor machine performance and track key performance indicators (KPIs) such as uptime, downtime, and overall equipment effectiveness (OEE).

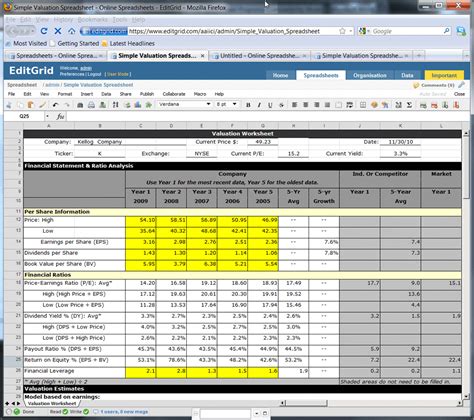

4. Analyze Maintenance Data

Utilize an Excel template to analyze maintenance data and identify trends and patterns. This can include tracking maintenance costs, labor hours, and frequency of repairs.

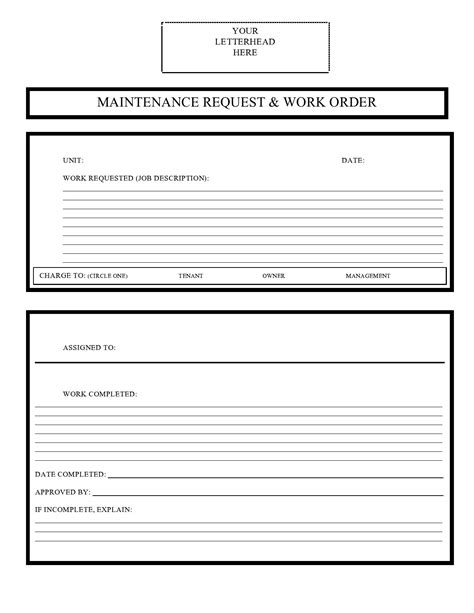

5. Create a Maintenance Request System

Set up an Excel template to create a maintenance request system that allows employees to submit requests for maintenance and repairs.

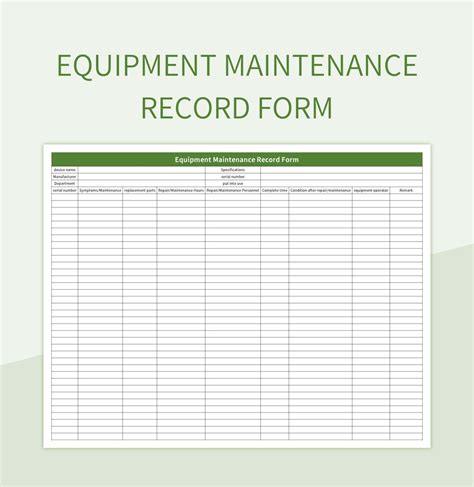

6. Track Maintenance History

Use an Excel template to track maintenance history for each machine, including details of past repairs, maintenance tasks, and inspections.

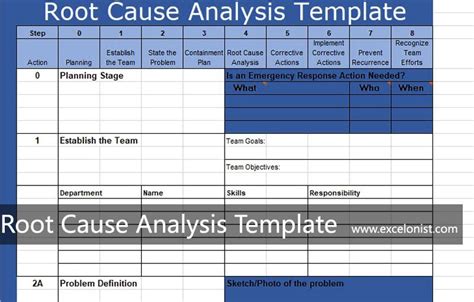

7. Conduct Root Cause Analysis

Utilize an Excel template to conduct root cause analysis (RCA) to identify the underlying causes of equipment failures and develop strategies to prevent future occurrences.

Implementing an Excel Template for Machine Maintenance

Implementing an Excel template for machine maintenance involves several steps, including:

- Identifying requirements: Determine the specific requirements of the maintenance team and the types of data that need to be tracked.

- Designing the template: Design a template that meets the identified requirements and is easy to use and understand.

- Populating the template: Populate the template with relevant data, including machine information, maintenance schedules, and inventory levels.

- Training users: Train maintenance team members on how to use the template and ensure that everyone is comfortable with the new system.

Best Practices for Using Excel Template for Machine Maintenance

Here are some best practices for using an Excel template for machine maintenance:

- Keep it simple: Keep the template simple and easy to use to ensure that all team members can understand and use it.

- Use clear headings: Use clear headings and labels to ensure that data is easy to identify and understand.

- Use formulas and functions: Use formulas and functions to automate calculations and reduce errors.

- Regularly review and update: Regularly review and update the template to ensure that it remains relevant and effective.

Conclusion

In conclusion, using an Excel template for machine maintenance can help optimize maintenance processes, improve efficiency, and reduce downtime. By following the seven ways outlined above and implementing an Excel template, maintenance teams can make data-driven decisions and improve overall equipment effectiveness.

Share Your Thoughts

Have you used an Excel template for machine maintenance? Share your experiences and best practices in the comments below.

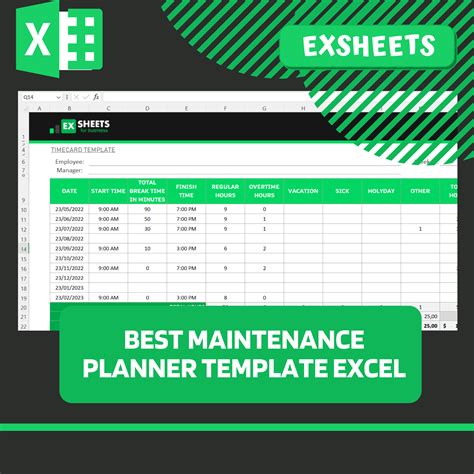

Gallery of Machine Maintenance Excel Templates

Machine Maintenance Excel Template Gallery

Frequently Asked Questions

Q: What is the purpose of using an Excel template for machine maintenance?

A: The purpose of using an Excel template for machine maintenance is to optimize maintenance processes, improve efficiency, and reduce downtime.

Q: How can I create a preventive maintenance schedule using an Excel template?

A: You can create a preventive maintenance schedule using an Excel template by setting up a table with columns for machine name, maintenance frequency, and due date.

Q: What are some best practices for using an Excel template for machine maintenance?

A: Some best practices for using an Excel template for machine maintenance include keeping it simple, using clear headings, and regularly reviewing and updating the template.