Intro

Discover the cutting-edge methods for superior joining technologies. Explore 5 innovative ways to enhance your manufacturing processes, including advanced welding techniques, precision bonding methods, and robust fastening systems. Improve product reliability, reduce costs, and increase efficiency with these expert-recommended joining technologies and material handling solutions.

In today's fast-paced manufacturing landscape, the ability to efficiently and effectively join materials is crucial for producing high-quality products. Superior joining technologies are essential for achieving strong, durable, and reliable bonds between materials, which can significantly impact the overall performance and lifespan of a product. In this article, we will explore five ways to achieve superior joining technologies, highlighting the benefits, working mechanisms, and practical applications of each method.

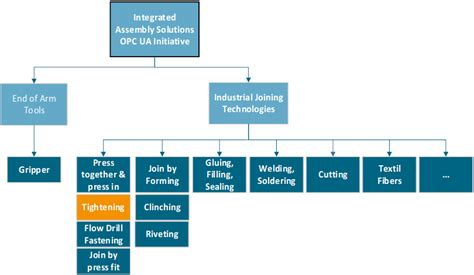

Understanding the Importance of Joining Technologies

Joining technologies play a vital role in modern manufacturing, enabling the creation of complex structures and assemblies from individual components. The quality of the join can significantly impact the overall performance, safety, and reliability of a product. Superior joining technologies can help manufacturers achieve improved product quality, reduced production costs, and increased efficiency.

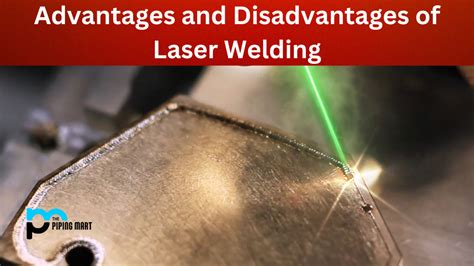

1. Laser Welding: A Precise and Efficient Joining Method

Laser welding is a high-precision joining method that uses a focused beam of light to melt and join materials. This process offers several benefits, including high accuracy, low heat input, and minimal distortion. Laser welding is commonly used in the aerospace, automotive, and medical industries, where precision and quality are paramount.

Benefits of Laser Welding

• High precision and accuracy • Low heat input and minimal distortion • Fast welding speeds • Ability to weld thin and delicate materials

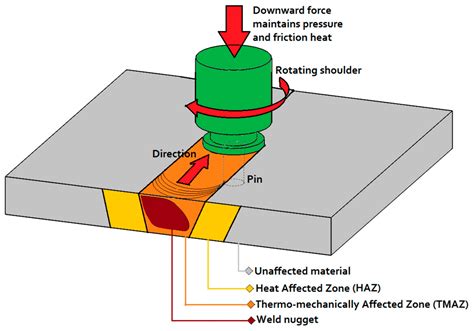

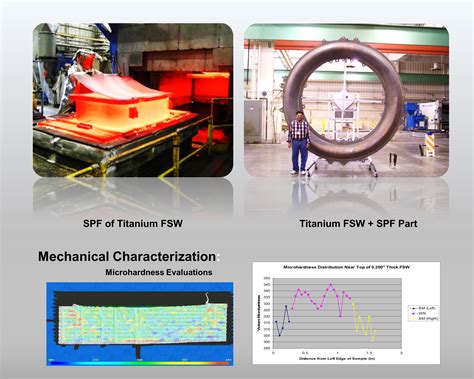

2. Friction Stir Welding: A Solid-State Joining Method

Friction stir welding (FSW) is a solid-state joining method that uses a rotating tool to heat and plasticize materials, creating a strong and durable bond. FSW offers several benefits, including low distortion, minimal heat input, and improved joint strength. This method is commonly used in the aerospace and automotive industries, where high-strength and lightweight materials are required.

Benefits of Friction Stir Welding

• Low distortion and minimal heat input • Improved joint strength and quality • Ability to weld thin and delicate materials • Low energy consumption

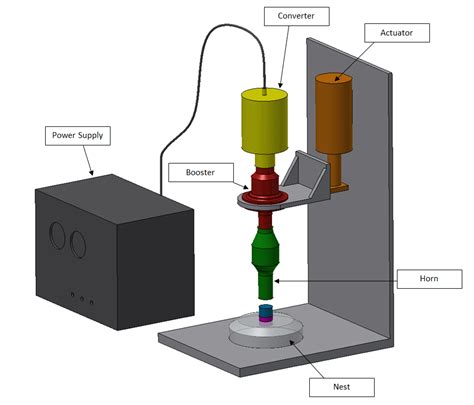

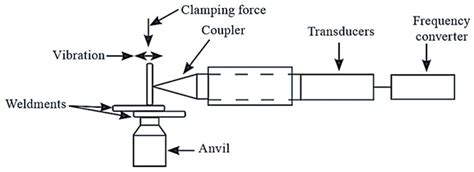

3. Ultrasonic Welding: A High-Frequency Joining Method

Ultrasonic welding is a high-frequency joining method that uses high-frequency vibrations to generate heat and create a strong bond between materials. This process offers several benefits, including fast welding speeds, low energy consumption, and minimal heat input. Ultrasonic welding is commonly used in the automotive and aerospace industries, where high-speed and high-volume production is required.

Benefits of Ultrasonic Welding

• Fast welding speeds and high-volume production • Low energy consumption and minimal heat input • Ability to weld thin and delicate materials • Improved joint quality and strength

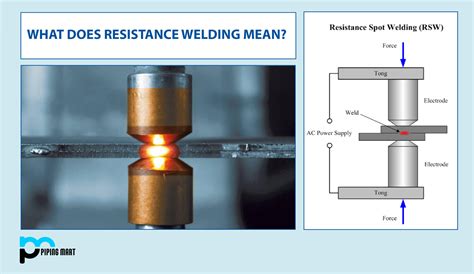

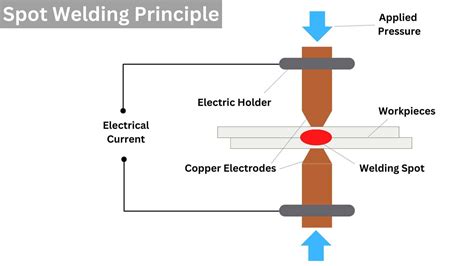

4. Resistance Spot Welding: A Cost-Effective Joining Method

Resistance spot welding (RSW) is a cost-effective joining method that uses electrical resistance to heat and join materials. This process offers several benefits, including low equipment costs, fast welding speeds, and minimal heat input. RSW is commonly used in the automotive and consumer goods industries, where high-volume production and cost-effectiveness are essential.

Benefits of Resistance Spot Welding

• Low equipment costs and high-volume production • Fast welding speeds and minimal heat input • Ability to weld thin and delicate materials • Improved joint quality and strength

5. Brazing: A Versatile Joining Method

Brazing is a versatile joining method that uses a filler material to create a strong and durable bond between materials. This process offers several benefits, including high joint strength, low distortion, and minimal heat input. Brazing is commonly used in the aerospace, automotive, and HVAC industries, where high-strength and durable joints are required.

Benefits of Brazing

• High joint strength and durability • Low distortion and minimal heat input • Ability to weld thin and delicate materials • Improved joint quality and reliability

Gallery of Joining Technologies Images

Joining Technologies Image Gallery

In conclusion, achieving superior joining technologies is crucial for manufacturers to produce high-quality products with strong, durable, and reliable bonds between materials. By understanding the benefits, working mechanisms, and practical applications of various joining methods, manufacturers can select the most suitable joining technology for their specific needs. Whether it's laser welding, friction stir welding, ultrasonic welding, resistance spot welding, or brazing, each joining method offers unique advantages and benefits that can significantly impact the overall quality and performance of a product.