Discover the crucial role of welding in the army, from equipment maintenance to fabrication of critical infrastructure. Learn about the 5 key roles of welding in military operations, including repair, modification, and creation of vital assets, leveraging LSI keywords: military fabrication, equipment repair, infrastructure development, and tactical operations.

Welding plays a vital role in the army, contributing significantly to the construction, maintenance, and repair of various military equipment and infrastructure. The importance of welding in the army cannot be overstated, as it is essential for ensuring the effectiveness and efficiency of military operations. In this article, we will explore the five key roles of welding in the army.

Role 1: Equipment Maintenance and Repair

Welding is crucial for maintaining and repairing military equipment, including tanks, trucks, and other vehicles. Army welders are responsible for ensuring that equipment is in good working condition, which is essential for military operations. They perform various welding tasks, such as repairing damaged armor, fixing broken axles, and replacing worn-out parts. By maintaining equipment in good condition, army welders help to prevent breakdowns and ensure that military operations run smoothly.

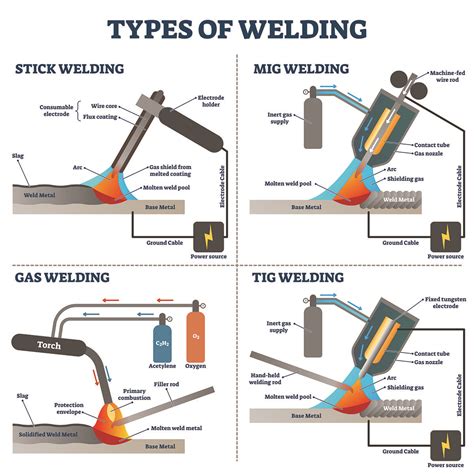

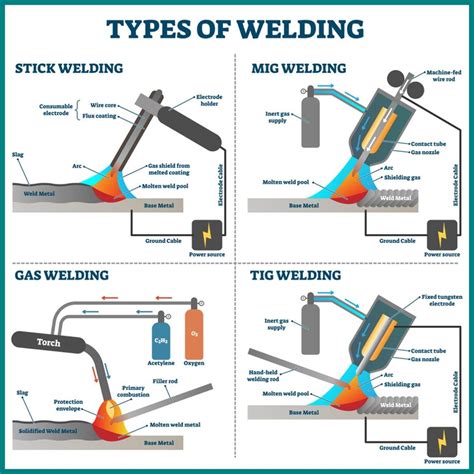

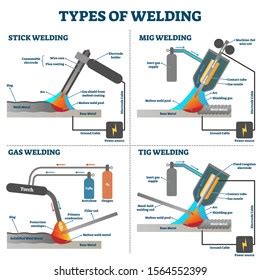

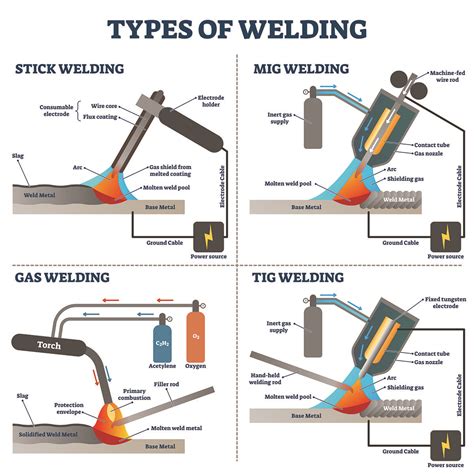

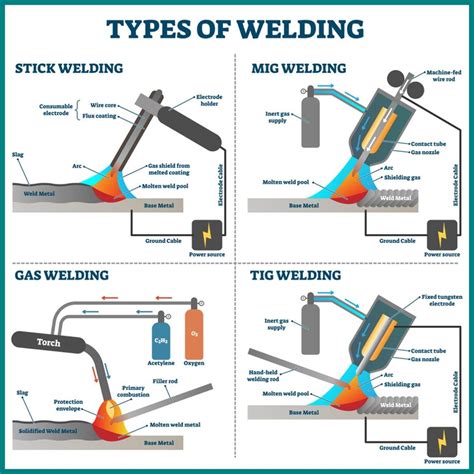

Welding Techniques Used in Equipment Maintenance

Army welders use various welding techniques, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW). These techniques allow them to repair and maintain a wide range of equipment, from small engines to large tanks.

Role 2: Construction of Military Infrastructure

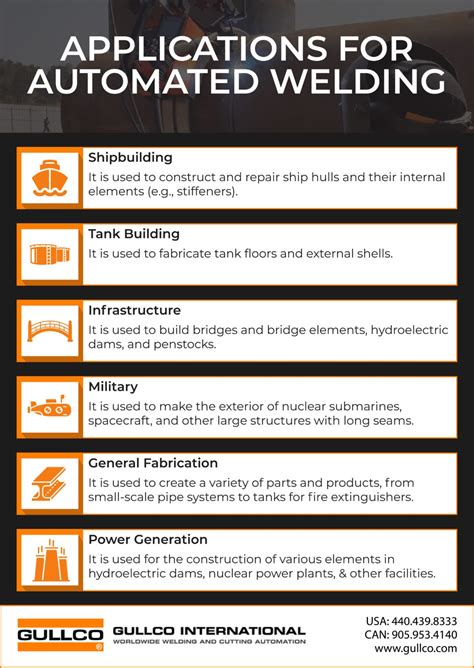

Welding plays a significant role in the construction of military infrastructure, including barracks, bridges, and other facilities. Army welders work with engineers and architects to design and build structures that meet military specifications. They use welding techniques to join steel beams, pipes, and other metal components, ensuring that structures are strong and durable.

Welding Materials Used in Construction

Army welders use a variety of welding materials, including steel, aluminum, and titanium. These materials are chosen for their strength, durability, and resistance to corrosion.

Role 3: Fabrication of Specialized Equipment

Welding is used to fabricate specialized equipment, such as mine rollers, explosive ordnance disposal (EOD) equipment, and other custom-made devices. Army welders work with engineers and technicians to design and build equipment that meets specific military requirements. They use welding techniques to join metal components, ensuring that equipment is strong, durable, and functional.

Welding Processes Used in Fabrication

Army welders use various welding processes, including manual welding, automated welding, and robotic welding. These processes allow them to fabricate complex equipment with high precision and accuracy.

Role 4: Research and Development

Welding plays a significant role in research and development (R&D) activities in the army. Army welders work with scientists and engineers to develop new materials, technologies, and techniques. They use welding to join advanced materials, such as composites and nanomaterials, and to test their properties and performance.

Welding Techniques Used in R&D

Army welders use advanced welding techniques, such as laser welding, electron beam welding, and friction stir welding. These techniques allow them to join complex materials and to study their behavior under various conditions.

Role 5: Training and Education

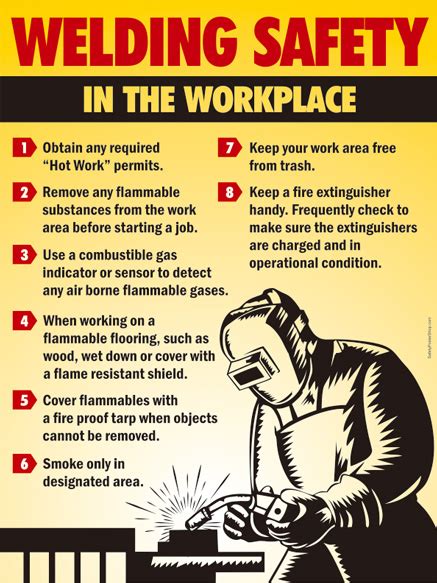

Welding is an essential skill for army personnel, and welding training is an integral part of military education. Army welders provide training and education to other soldiers, teaching them welding techniques, safety procedures, and equipment operation. They also develop and update training manuals and programs to ensure that soldiers have the necessary skills to perform welding tasks effectively.

Welding Training Programs

Army welders participate in various training programs, including apprenticeships, certification programs, and continuing education courses. These programs help them to develop and maintain their welding skills, ensuring that they are proficient in the latest techniques and technologies.

Welding in the Army Image Gallery

In conclusion, welding plays a vital role in the army, contributing significantly to equipment maintenance, construction, fabrication, research and development, and training and education. Army welders are skilled professionals who use various welding techniques, materials, and processes to perform their tasks effectively. By highlighting the importance of welding in the army, we hope to raise awareness about the critical role that welding plays in military operations.

We invite you to share your thoughts and experiences about welding in the army. Have you served in the military and worked as a welder? What were some of the challenges you faced, and how did you overcome them? Share your stories and comments below.