Discover the truth about aluminums brittleness. Learn how aluminums unique properties, such as its ductility and malleability, affect its susceptibility to cracking and breaking. Explore the factors that influence aluminums brittleness, including its alloy composition, processing methods, and environmental conditions. Get the facts on aluminums strength and durability.

Aluminum is one of the most widely used metals in the world, and its properties have made it an essential material in various industries, from aerospace to packaging. However, one question that often arises is whether aluminum is a brittle metal. To answer this, we need to delve into the world of materials science and understand the properties of aluminum.

What is Brittleness in Metals?

Brittleness in metals refers to the tendency of a material to break or shatter without undergoing significant plastic deformation. In other words, a brittle metal will snap or fracture when subjected to stress, rather than bending or deforming. This is in contrast to ductile metals, which can undergo significant deformation before failing.

Factors Affecting Brittleness in Metals

Several factors can contribute to brittleness in metals, including:

- Crystal structure: Metals with a face-centered cubic (FCC) crystal structure, such as aluminum, tend to be more ductile than those with a body-centered cubic (BCC) structure.

- Alloying elements: The presence of certain alloying elements, such as silicon or iron, can affect the brittleness of a metal.

- Temperature: Metals can become more brittle at low temperatures or when exposed to thermal stress.

- Processing history: The way a metal is processed, including rolling, forging, or casting, can influence its brittleness.

Is Aluminum a Brittle Metal?

Aluminum is generally considered a ductile metal, meaning it can undergo significant plastic deformation before failing. However, under certain conditions, aluminum can exhibit brittle behavior.

For example:

- At low temperatures, aluminum can become more brittle, making it more prone to cracking or shattering.

- When exposed to thermal stress, such as during welding or casting, aluminum can become more brittle due to the formation of defects or micro-cracks.

- Certain aluminum alloys, such as those containing high levels of silicon or iron, can be more brittle than others.

Why is Aluminum Used Despite its Brittleness?

Despite its potential for brittleness, aluminum remains a widely used metal due to its many advantages, including:

- Low density: Aluminum is one-third the density of steel, making it an ideal material for applications where weight is a concern, such as in aerospace or transportation.

- Corrosion resistance: Aluminum has a naturally occurring oxide layer that provides excellent corrosion resistance, reducing the need for additional coatings or treatments.

- Electrical conductivity: Aluminum is an excellent conductor of electricity, making it widely used in electrical applications, such as wiring or circuitry.

- Recyclability: Aluminum is highly recyclable, reducing waste and conserving natural resources.

Applications of Aluminum

Aluminum's unique combination of properties makes it an ideal material for a wide range of applications, including:

- Aerospace: Aluminum is used in aircraft and spacecraft due to its high strength-to-weight ratio and resistance to corrosion.

- Packaging: Aluminum is widely used in food and beverage packaging due to its corrosion resistance and ability to be easily formed into complex shapes.

- Transportation: Aluminum is used in the manufacture of vehicles, including cars, buses, and bicycles, due to its low density and high strength-to-weight ratio.

- Electrical: Aluminum is used in electrical applications, such as wiring or circuitry, due to its high electrical conductivity.

Future Developments in Aluminum

Researchers are continually working to improve the properties of aluminum, including its brittleness. Some potential developments include:

- New alloying elements: Researchers are exploring the use of new alloying elements to improve the strength and ductility of aluminum.

- Advanced processing techniques: New processing techniques, such as 3D printing or advanced casting methods, are being developed to improve the properties of aluminum.

- Composite materials: Researchers are investigating the use of composite materials, such as aluminum-matrix composites, to improve the strength and ductility of aluminum.

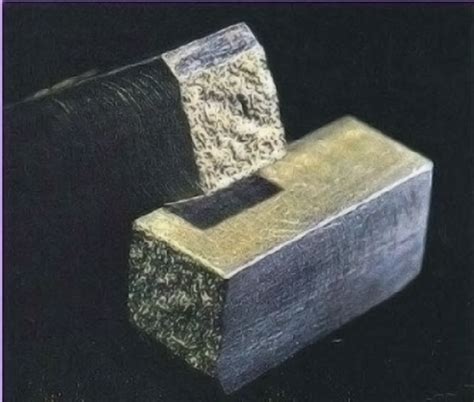

Aluminum Image Gallery

In conclusion, while aluminum can exhibit brittle behavior under certain conditions, it is generally considered a ductile metal. Its unique combination of properties makes it an ideal material for a wide range of applications, from aerospace to packaging. As researchers continue to develop new alloys and processing techniques, we can expect to see even more innovative uses of aluminum in the future.