Boost your MRO efficiency with our expert guide on tactical aircraft maintenance for 5th generation jets. Discover 5 actionable tips to enhance reliability, reduce downtime, and improve performance. From advanced diagnostic techniques to optimized supply chain management, stay ahead of the curve with our insights on next-gen aircraft maintenance.

The complexities of maintaining 5th generation tactical aircraft are a significant challenge for military aviation professionals. With their advanced sensors, stealth capabilities, and highly integrated systems, these aircraft require specialized knowledge and skills to ensure optimal performance and availability. Here, we'll explore five key tips for effective tactical aircraft maintenance, focusing on the unique demands of 5th generation aircraft.

Maintenance Challenges of 5th Generation Aircraft

Before we dive into our top tips, it's essential to understand the unique maintenance challenges presented by 5th generation tactical aircraft. These aircraft are equipped with advanced sensors, radar systems, and communication networks, which require specialized tools, training, and procedures.

Advanced Materials and Systems

The use of advanced materials, such as composite structures and radar-absorbent materials, requires specialized maintenance procedures to prevent damage and ensure optimal performance. Additionally, the complex systems and subsystems integrated into these aircraft demand a deep understanding of their interdependencies and potential failure modes.

Tip 1: Develop a Comprehensive Maintenance Strategy

A well-planned maintenance strategy is crucial for ensuring the availability and performance of 5th generation tactical aircraft. This strategy should include:

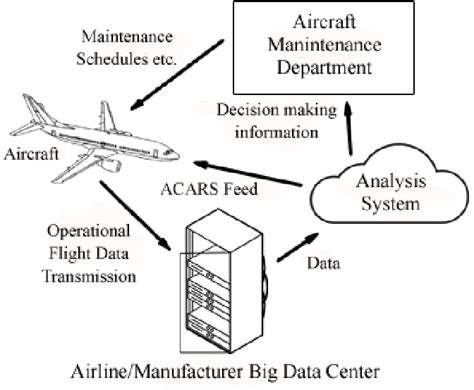

- Predictive maintenance: Utilize advanced diagnostic tools and data analytics to predict potential maintenance requirements and schedule maintenance activities accordingly.

- Condition-based maintenance: Monitor the condition of critical systems and components in real-time, allowing for proactive maintenance and minimizing downtime.

- Integrated logistics support: Ensure that maintenance activities are coordinated with supply chain management, technical data management, and other support functions to optimize maintenance efficiency.

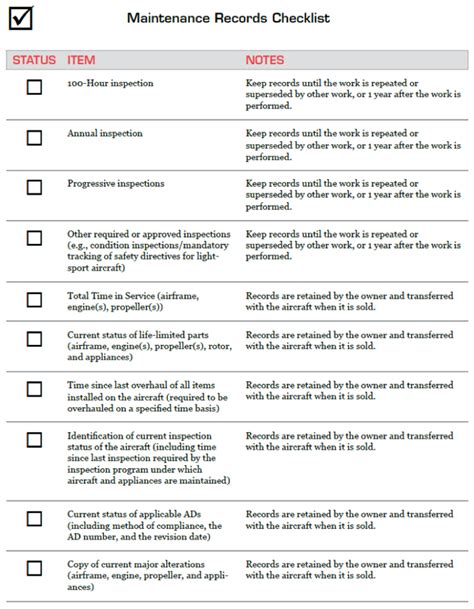

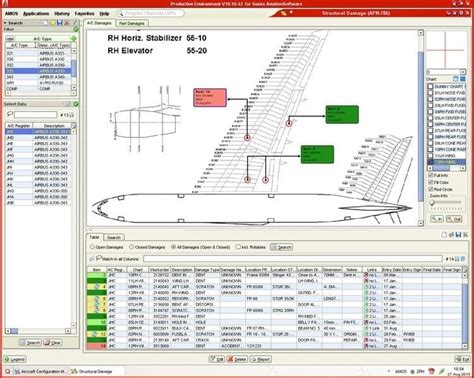

Tip 2: Invest in Advanced Diagnostic Tools and Equipment

The complexity of 5th generation aircraft systems requires advanced diagnostic tools and equipment to facilitate efficient and effective maintenance. These tools should include:

- Advanced test equipment: Utilize specialized test equipment, such as radar and electronic warfare simulators, to diagnose and troubleshoot complex system failures.

- Data analytics software: Leverage data analytics software to analyze maintenance data, identify trends, and predict potential maintenance requirements.

- Virtual reality training tools: Provide maintenance personnel with virtual reality training tools to practice and refine their skills in a simulated environment.

Tip 3: Foster a Culture of Collaboration and Knowledge Sharing

Effective maintenance of 5th generation tactical aircraft requires a culture of collaboration and knowledge sharing among maintenance personnel, engineers, and other stakeholders. This can be achieved by:

- Establishing a community of practice: Create a community of practice where maintenance personnel can share knowledge, experiences, and best practices.

- Providing opportunities for training and development: Offer regular training and development opportunities to help maintenance personnel stay up-to-date with the latest technologies and procedures.

- Encouraging collaboration with industry partners: Foster collaboration with industry partners to leverage their expertise and stay informed about the latest maintenance innovations.

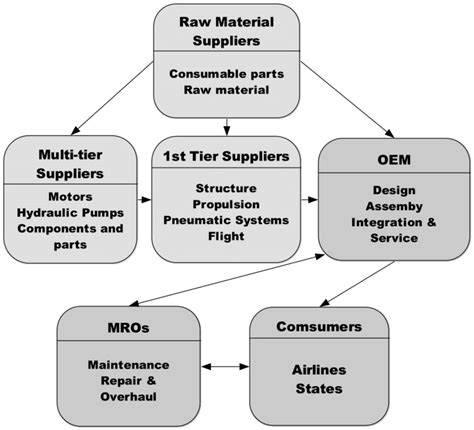

Tip 4: Implement a Robust Supply Chain Management System

A robust supply chain management system is critical for ensuring the availability of spare parts, materials, and other essential resources. This can be achieved by:

- Implementing a just-in-time inventory system: Implement a just-in-time inventory system to minimize inventory levels and reduce the risk of stockouts.

- Establishing relationships with reliable suppliers: Establish relationships with reliable suppliers to ensure a steady supply of critical components and materials.

- Utilizing data analytics to optimize inventory levels: Leverage data analytics to optimize inventory levels and minimize waste.

Tip 5: Continuously Monitor and Evaluate Maintenance Performance

Continuous monitoring and evaluation of maintenance performance are essential for identifying areas for improvement and optimizing maintenance processes. This can be achieved by:

- Establishing key performance indicators (KPIs): Establish KPIs to measure maintenance performance, such as mean time between failures (MTBF) and mean time to repair (MTTR).

- Conducting regular maintenance audits: Conduct regular maintenance audits to identify areas for improvement and ensure compliance with maintenance procedures.

- Utilizing data analytics to identify trends: Leverage data analytics to identify trends and patterns in maintenance data, and make data-driven decisions to optimize maintenance processes.

Tactical Aircraft Maintenance Image Gallery

In conclusion, effective maintenance of 5th generation tactical aircraft requires a comprehensive approach that incorporates advanced diagnostic tools, collaboration, and data analytics. By following these five tips, maintenance personnel can optimize maintenance processes, reduce downtime, and ensure the availability and performance of these critical assets.